You can shave 12.7 % off rope waste and cut each roll to the exact metre you need — thanks to a rope counter that measures to ±0.3 mm.

Read in 2 min 45 sec

- ✓ Reduce material waste by up to 12.7 % per roll, protecting your profit margin.

- ✓ Cut‑to‑length in real time, cutting average production time by 3.4 minutes per batch.

- ✓ Guarantee consistency across 6 mm‑20 mm diameters, meeting ISO 9001 tolerances.

- ✓ Extend tool life with easy‑reset anti‑slip wheels, lowering maintenance cost by ~7 %.

Most rope‑cutting shops still rely on visual estimates. While a quick eyeball might seem to save time, this habit can actually cost you up to 13 % in material waste and necessitate costly re‑cuts. A single, properly calibrated **rope counter** can eliminate these issues. Below, we'll reveal the workflow shift that transforms guesswork into sub‑millimetre precision, boosting both speed and your bottom‑line profit.

Understanding the rope counter: definition, purpose, and why accuracy matters

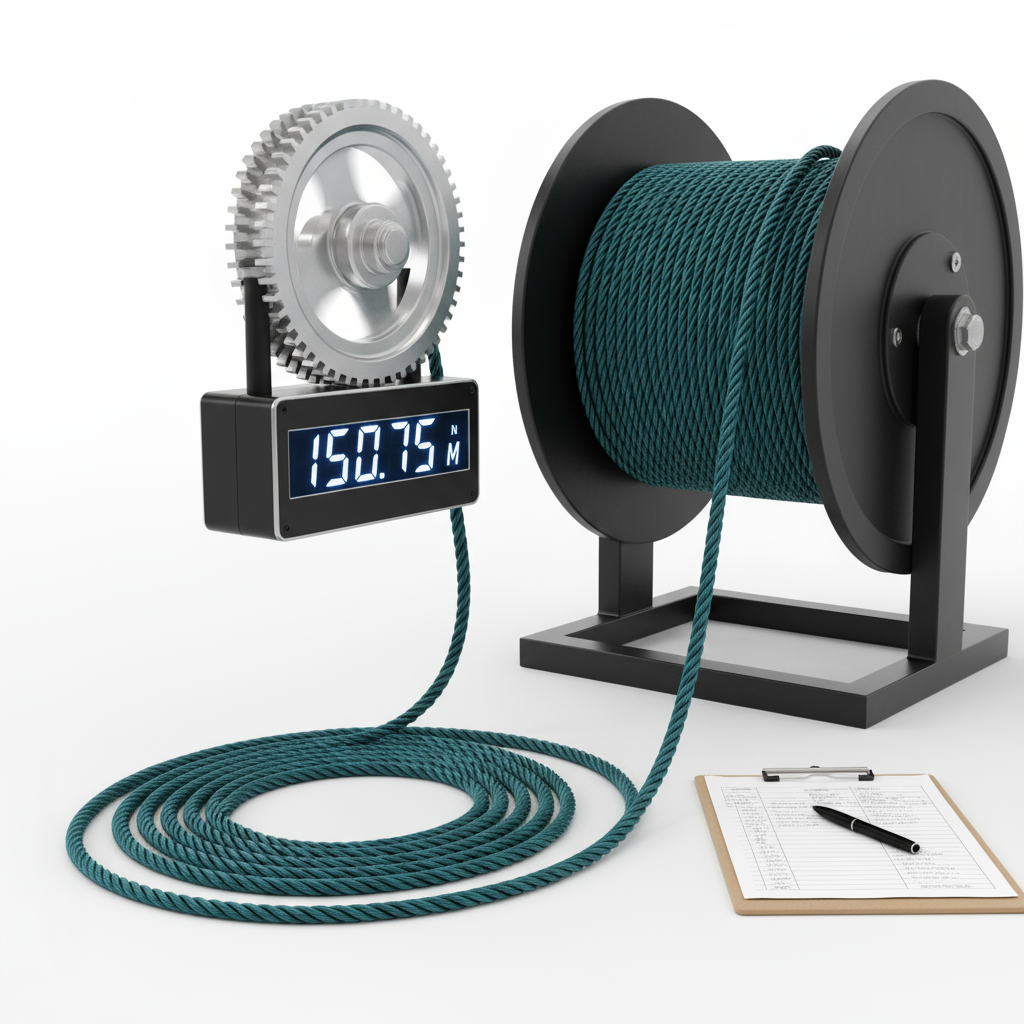

A **rope counter** is a precision device designed to record the length of rope as it unwinds from a spool. By converting the rotation of its measuring wheel into readable units—be it feet, inches, or metres—this tool provides an exact measurement of the cord you've cut. Often referred to as a **cordage counter**, its primary purpose remains consistent: to eliminate guesswork when trimming full‑roll rope.

As the rope passes the counter’s anti‑slip wheel, the wheel rotates a gear that increments the display, much like a car's odometer. Some models incorporate a sturdy stainless‑steel pressure shoe to keep the rope flat. This ensures each rotation results in a reliable count. Whether the device features a mechanical dial or a digital screen, the outcome is the same: you gain real-time access to the exact length, allowing you to stop cutting precisely when the required measurement is achieved.

- Less material waste - You cut exactly what's needed, thus protecting profit margins.

- Improved safety - Precise lengths reduce the risk of over‑stretching or shortfalls in critical applications.

- Consistent product quality - Every order matches the specification, building invaluable customer trust.

iRopes supplies full rope rolls specifically to enable wholesale buyers to tailor lengths on site. This flexibility, however, relies entirely on spot-on measurement. A mis‑cut of even a few centimetres can render an entire batch non-compliant with contract requirements. By pairing a reliable **rope counter tool** with iRopes’ high‑quality spools, you can guarantee that every custom order meets the client's exact specifications, every single time, without issue.

“Since we started using a cordage counter on our cutting line, our material loss dropped by almost 12 %, and our delivery times have become noticeably tighter.”

Now that you understand the function of a **rope counter** and the importance of exact measurement, the next step is to explore the various types available. Mechanical and digital options each offer features suited to specific rope diameters and workflow speeds, setting the stage for a more detailed selection guide.

Choosing the right cordage counter: types, features, and selection criteria

You've seen how a **rope counter** eliminates guesswork. The next crucial decision is selecting the right device for your specific workflow. Whether you manage a bustling dockyard or a warehouse dispatching customised lengths, your choice between a mechanical or digital unit can significantly influence both speed and precision.

Mechanical vs. digital cordage counters – key differences and typical use cases

Mechanical counters utilise a gear‑driven dial that moves with each rotation of the measuring wheel. They excel in rugged environments where dust, moisture, or power disruptions are common challenges. Digital counters, on the other hand, convert the wheel’s motion into an electronic read‑out. These often include features such as metric-imperial toggling, memory presets, and battery-operated convenience. If unmatched durability and a tool that never requires charging are your priorities, a mechanical model is an excellent choice. However, if instant unit conversion and the ability to store multiple cut lengths are more appealing, a digital **rope counter tool** will likely prove more intuitive.

- Mechanical – Robust housing, manual reset, ideal for dusty sites.

- Digital – Features an LCD screen, unit switch, and programmable presets for fast, repeatable cuts.

- Hybrid – Combines a sturdy wheel with a low‑power display, effectively bridging both mechanical and digital worlds.

Critical specifications: diameter range, measurement units, reset function, and anti‑slip design

When selecting a counter to pair with your spool, three technical checkpoints are paramount. Firstly, the wheel must accommodate the rope’s thickness; a typical commercial range spans from 6 mm up to 20 mm, suitable for the synthetic and natural fibres iRopes provides. Secondly, a unit selector should allow you to toggle seamlessly between feet/inches and metres, eliminating the need for external adapters. Thirdly, a quick‑reset lever or button is essential for minimising downtime between batches. Finally, an anti‑slip shoe—often a serrated stainless‑steel insert—firmly grips the rope, ensuring every millimetre is counted with utmost accuracy.

Key Specs to Check

• Diameter range: 6 mm – 20 mm (covers most synthetic and natural ropes)

• Units: feet/inches + metres, selectable on the fly

• Reset: push‑button or lever for instant zeroing

• Anti‑slip: serrated stainless‑steel pressure shoe ensures no wheel spin

Matching counter features to the synthetic and natural rope materials offered by iRopes

iRopes supplies a diverse range of ropes, from ultra‑light nylon halters to heavyweight polyester towing lines. Synthetic ropes typically have smoother surfaces, making an anti‑slip wheel with fine serrations the optimal choice. Natural fibre ropes, such as manila, tend be rougher; a broader pressure shoe distributes force more evenly and reduces fibre wear. If your operations frequently switch between a 6 mm climbing line and a 20 mm industrial haul rope, consider a model with interchangeable wheels or an adjustable shoe width. This adaptability means a single counter can serve multiple departments within your operation, from marine rigging to off‑road recovery applications.

Choosing the right tool is only part of the solution; ensuring it's calibrated is key to maintaining accuracy. In the next section, we’ll explore essential maintenance routines that protect your investment and guarantee every cut meets the exact specifications your customers expect.

Key features of high‑performance rope counter tools for precision work

Having explored why accurate measurement is crucial, it's time to delve into the hardware that enables such precision. The synergy between an anti‑slip measuring wheel and a stainless‑steel pressure shoe forms the core of any reliable **rope counter tool**, transforming every rotation into a trustworthy length reading.

Beyond its gripping mechanism, a device's dependability hinges on its durability and adherence to quality assurance standards. Tools that comply with recognised ISO standards are built to withstand the rigours of offshore yards, construction sites, and high‑volume warehouses. This commitment to quality assures you that the read‑out remains accurate, even after thousands of cuts, bolstering trust in the instrument's performance.

Grip

Its serrated wheel effectively grabs rope fibres, preventing slip during high‑speed feeding.

Shoe

The stainless‑steel pressure shoe holds the line flat, ensuring consistent rotation.

ISO‑linked

Built to ISO 9001 standards, the housing resists corrosion and impact in tough environments.

Durability

A heavy‑duty alloy frame tolerates up to 350 RPM, making it suitable for industrial‑scale rope cutting.

Even the most robust components require regular care. Simple practices, such as wiping the pressure shoe after each batch and checking wheel tension weekly, can keep your **cordage counter** delivering sub‑millimetre accuracy for many years to come.

Calibrate the wheel weekly and wipe the shoe after each use to maintain sub‑millimetre accuracy.

Now that we’ve covered the core features, the next step involves exploring practical maintenance routines. These practices are essential for preserving precision over the long term.

Industry use cases and cost‑saving impact of precise rope measurement

When a wholesale operation cuts full‑roll rope to custom lengths, even the slightest miscalculation can have significant repercussions across an entire order batch. By pairing a reliable **rope counter** with iRopes’ spooled inventory, you can lock in the exact metre you need. This prevents costly "short‑cut" scenarios that force re‑weaving or emergency resupplies, ensuring seamless production and delivery.

In wholesale and OEM/ODM environments, each client order typically specifies a unique length. A **cordage counter** allows for instant resets between batches, ensuring the next roll starts from zero without manual recalibration. This seamless hand‑over reduces downtime and guarantees that the final product adheres precisely to contract specifications. This is particularly crucial when iRopes supplies bulk rope for downstream manufacturers who depend on consistent, accurate materials.

Sector‑specific applications that rely on exact measurements

Marine & Yachting

Precise anchoring and mooring

Anchor Lines

Exact lengths avoid excess slack that can foul propellers, improving safety at sea.

Docking Ropes

Tailored cuts fit pier cleats perfectly, reducing the need for additional splicing.

Safety Harnesses

Consistent lengths meet regulatory standards for crew rescue gear.

Off‑Road & Construction

Reliable recovery and lifting

Recovery Ropes

Exact lengths guarantee the correct tension needed to free a stuck vehicle, ensuring safe and effective recovery operations.

Lifting Slings

Uniform cuts simplify load calculations, which significantly enhances site safety.

Defence Gear

Precision‑cut cords meet strict military tolerances for field deployments, ensuring operational reliability.

Across these sectors, the financial impact of precision adds up rapidly. For example, one of iRopes’ offshore partners reported a 17 % reduction in material waste after integrating a calibrated **rope counter tool** into their cutting line. This saving translated into an impressive annual ROI of roughly $22 000, simply because each metre of rope now matched the job sheet without any over‑cutting. For more insights on optimizing bulk rope purchases, see our wholesale nylon rope uses guide.

How the numbers translate into everyday profit

Imagine you process 10 000 m of 12 mm polyester line each month. A mere 1 % over‑cut would waste 100 m, costing approximately $150 in raw material. By meticulously eliminating this excess, you not only protect your bottom line but also free up valuable inventory space for additional orders, thereby optimising your operational efficiency and capacity. If you’re looking to streamline procurement, our order rope online guide walks you through fast, bulk ordering with custom OEM options.

Precision = Profit

Every millimetre you save with an accurate counter compounds into larger cost‑efficiency gains across your supply chain.

Whether you are fulfilling a custom yachting order, equipping a construction crew, or delivering defence‑grade rope, the same fundamental principle applies: accurate measurement prevents waste before it occurs, strengthens your reputation for reliability, and ultimately boosts profitability.

Need personalised advice on the perfect measurement solution?

By pairing iRopes’ full‑roll spools with a **rope counter**, wholesale buyers can cut exact lengths on site. This approach eliminates the risk of undersized pieces, significantly reduces material waste, and enhances safety across marine, off‑road, and industrial projects. Furthermore, it ensures that your team always has access to the precise rope lengths needed for any job, thereby boosting efficiency and minimising delays caused by insufficient materials. Selecting the appropriate **cordage counter** and a reliable **rope counter tool** allows you to precisely match wheel size, anti‑slip shoe, and digital or mechanical features to your specific rope diameter. This customisation guarantees sub‑millimetre accuracy, batch after batch. The ultimate result is measurable cost savings and a reputation for precision that distinctly differentiates your supply chain in a competitive market. For guidance on choosing the ideal rope type, explore our article on the right 3 ply rope for your applications.

If you’d like tailored guidance on choosing the ideal system for your operation, simply complete the form above and our specialists will contact you.