3‑strand twisted polyester rope offers outstanding UV stability (≈90% strength retention in prolonged sun) and predictable low stretch (~20%) — a dependable choice for outdoor and industrial jobs.

Key takeaways – ~2 min read

- ✓ UV resistance retains about 90% strength after extended sun exposure and can extend service life by ~30% in documented marine cases.

- ✓ Low‑stretch (~20% elongation) delivers predictable load handling; field crews report up to 15% faster rig‑ups.

- ✓ Abrasion durability is excellent and typically outperforms nylon on rough surfaces.

- ✓ Custom OEM/ODM options let you brand the rope while maintaining ISO 9001 quality controls.

You’ve probably dealt with splices that slip, lines that creep under load, and sun‑bleached ropes needing early replacement. The game‑changer is the three‑strand twisted polyester design, which helps reduce splicing time and preserves colour during long UV exposure. Read on for strength tables, step‑by‑step sizing, and iRopes’ custom‑order workflow so you can turn these advantages into a practical plan for your next job.

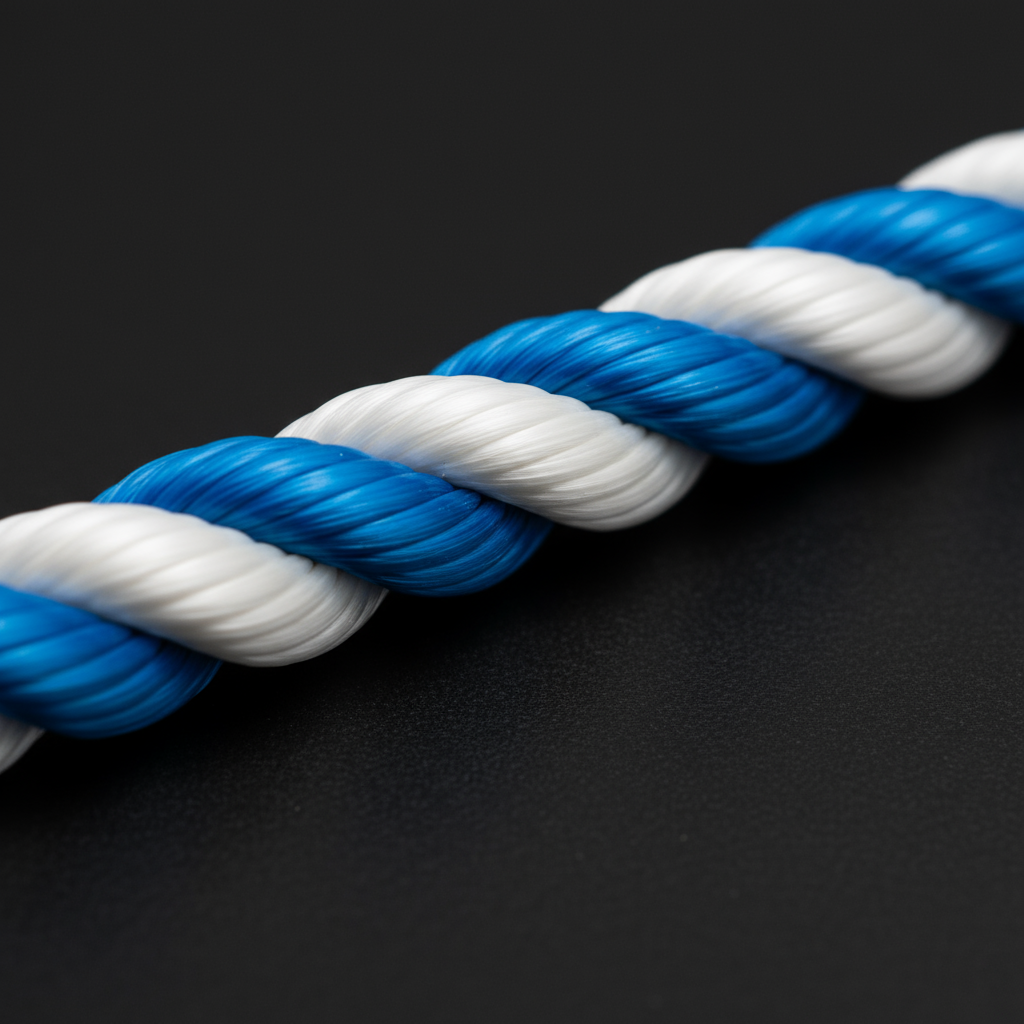

polyester twisted rope – Definition and Core Benefits

Twisted polyester rope is a 3‑strand rope made from 100% filament polyester fibres in a balanced four‑stage twist, delivering high strength, low stretch, and excellent UV resistance. These benefits also extend to other woven polyester constructions (e.g., solid‑braid and double‑braid), where the outer sheath provides strong wear and UV protection.

Key Benefits of polyester twisted rope

- UV resistance - polyester retains around 90% of its strength after prolonged sun exposure.

- Low stretch - elongation is typically ~20% under load, giving predictable performance.

- Abrasion durability - the outer strands resist cuts and scrapes, extending service life.

Compared with a solid‑braid design, the differences are clear. A solid braid weaves all fibres into a tight sheath, which can be stiffer and harder to splice. In contrast, the three separate strands of a twisted rope allow straightforward splicing and, when handled with the correct lay, help mitigate the dreaded “hockling” issue. Because each strand follows its own twist direction, the rope flexes naturally around pulleys and knots — a benefit you’ll notice on a sailing deck or a tree‑climbing rig.

“After switching to the three‑strand version for our marina rails, the rope held its colour after 12 months of harsh sun, and we estimate a 30% improvement in service life.” — Marine rigging supervisor

twisted polyester rope – Technical Specifications and Performance

Now that you know what twisted polyester rope is and why its three‑strand design matters, let’s look at the numbers that determine whether it will meet your project’s demands.

Below is a compact spec table capturing the most relevant data for common sizes. The values reflect industry‑standard test ranges.

| Diameter (in) | Weight /100 ft (lb) | Breaking Strength (lb) | Safe Working Load (SWL) (lb) |

|---|---|---|---|

| 0.25 | 2 | 1,490 | 298 |

| 0.50 | 8 | 5,900 | 1,180 |

| 0.75 | 18 | 12,500 | 2,500 |

| 1.00 | 32 | 22,000 | 4,400 |

| 1.50 | 70 | 44,500 | 8,900 |

| 2.00 | 103 | 80,600 | 16,120 |

The breaking strength column directly answers “What is the breaking strength of 3‑strand polyester rope?” — match your required load against the table, then apply a safety factor of at least five to arrive at the SWL.

- Check the diameter that fits your load requirement.

- Locate the corresponding breaking strength in the table.

- Divide that number by five to obtain the safe working load.

How does this material stack up against the ever‑popular nylon alternative? The side‑by‑side comparison below highlights the most asked‑about attributes.

| Property | Twisted Polyester Rope | Nylon Rope |

|---|---|---|

| UV resistance | Extremely high — retains ≈90% strength after prolonged sun exposure | Lower — degrades faster in outdoor UV |

| Stretch (under load) | ≈ 20% elongation (low stretch) | ≈ 30% elongation (higher stretch) |

| Water absorption | < 1% (minimal change when wet) | 6–12% (adds weight and reduces strength) |

| Abrasion durability | Excellent — outer strands resist cuts and scrapes | Good but wears faster on rough surfaces |

Because polyester absorbs almost no water and resists UV fading, it stays consistent in weight and retains its colour even after years on a sailing deck or a tree‑work rig. Those advantages become especially clear when you compare nylon’s higher stretch and moisture‑related strength loss.

With specs clarified, we can now explore real‑world uses and how to size the 3 strand twisted polyester rope correctly — including a quick calculation for a 1,000 lb load.

3 strand twisted polyester rope – Applications and Sizing Guide

With the technical specs in mind, it’s time to see where the rope really shines. Whether you’re hauling a sail, securing a tree, camping off‑grid, or tying down heavy equipment, the same core properties translate into real‑world reliability.

Below are the sectors that most often reach for a 3 strand twisted polyester rope. Each industry benefits from the same blend of UV durability, abrasion resistance, and predictable elongation.

Industries

Where professionals rely on the rope

Marine rigging

Handles constant sun, salt spray and dynamic loads on sailing vessels.

For detailed guidance on using three‑strand polyester rope for mooring and anchoring, see our dedicated article.

Arborist work

Low stretch lets climbers position gear precisely while climbing trees.

Industrial tie‑downs

Resists abrasion from metal edges and retains strength after repeated use.

Camping

Reliable guy‑lines and general‑purpose cordage that won’t fade or soak up water.

Rescue and safety

Predictable elongation helps maintain control under load and around hardware.

Sizing guide

Step‑by‑step to a safe working load

Step 1

Identify the maximum load you expect to carry.

Step 2

Match that load to a diameter using the spec table (breaking strength ÷ 5 = SWL).

Step 3

Confirm the chosen size meets any regulatory safety factor (usually ≥ 5).

Applying those steps to a common request — a 1,000 lb load — is straightforward. First, divide 1,000 lb by the safety factor of 5, giving a required safe working load of 200 lb. Looking at the spec table, a 0.25‑inch rope provides a SWL of 298 lb, which covers the load but leaves little margin for dynamic forces. The next size up, a 0.50‑inch 3 strand twisted polyester rope, offers a SWL of 1,180 lb, providing a comfortable safety cushion. Therefore, for a 1,000 lb requirement, the 0.50‑inch diameter is the recommended choice.

Custom options

iRopes can colour‑match the rope to your brand, add eye splices, thimbles or a printed logo, and safeguard your design with dedicated IP protection — all while maintaining the performance figures you calculated.

With the industry list, the sizing method, and the exact rope size for a 1,000 lb load, you can now choose colour, end terminations, and bulk‑order quantities — topics we’ll explore next.

Customization, Buying Tips, and Maintenance

Now that you’ve identified the right diameter, the next step is to make the rope truly yours — from colour and end fittings to the way you purchase it.

iRopes offers a full OEM/ODM package: choose any colour, specify eye splices, thimbles or printed logos, and rely on ISO 9001‑backed quality control with dedicated IP protection. The result is a rope that looks like yours and still meets the same breaking‑strength tables you saw earlier. If you need marine‑grade dock lines, explore our custom New England dock lines guide for additional insight.

Buying guide — retail price per foot typically ranges from $0.17 to $0.24. Bulk tiers commonly run about $50–$150 for 600‑ft spools and $150–$350 for 1,200‑ft coils. Stocked sizes usually dispatch within 1 day; custom colours and terminations require about 2–3 weeks. iRopes can ship pallets directly to your location worldwide, with neutral or customer‑branded packaging (bags, colour boxes, or cartons).

If you need to join two lengths without causing hockling, follow this five‑step routine for twisted polyester rope. The method keeps the three strands aligned and preserves the low‑stretch characteristic you rely on.

- Lay the rope ends parallel and trim both ends cleanly.

- Unwind each of the three strands a few inches to expose the core.

- Cross the left‑hand strand over the centre, then the right‑hand over the new centre, creating a simple three‑strand braid.

- Tighten the braid evenly while maintaining the original twist direction of each strand.

- Seal the splice with heat‑shrink or a polyester whipping to improve abrasion resistance.

Regular care will keep your rope performing for years. A quick maintenance checklist looks like this: clean with mild soap and fresh water, rinse and air‑dry out of direct sunlight, store coiled on a dry rack away from chemicals, inspect the outer strands for cuts before each use, and replace any rope that shows fraying or excessive wear.

With colour, terminations and buying strategy sorted, you’re ready to place a bulk order or request a sample with the exact finish you need. The next logical step is to request a free technical quote from iRopes so you can compare pricing against your project budget.

Need a personalised rope solution?

The guide has shown how the three‑strand construction of polyester twisted rope creates a structure that delivers outstanding wear and UV resistance while keeping stretch low and strength high. With clear tables for the breaking strength of twisted polyester rope and a simple safety‑factor formula, you can confidently pick the right diameter for a 1,000 lb load. The 3 strand twisted polyester rope also offers easy customisation of colour, terminations and IP‑protected OEM/ODM solutions, making it ideal for marine, arborist, camping and industrial applications. iRopes backs every order with ISO 9001 quality assurance and global, on‑time shipping. For more on selecting the best ship mooring rope, explore our comparative guide.

If you’d like personalised guidance on selecting the perfect size, colour or termination for your project, simply complete the form above and our rope specialists will reply promptly.