Choose the perfect marine rope – Spectra’s ultra‑light line delivers 2–3× the strength‑to‑weight of polyester and nylon, with < 1 % stretch.

Your quick wins at a glance

- ✓ Choose faster with side‑by‑side specs

- ✓ Match load ratings with confidence

- ✓ Optimise total cost over the rope’s service life

Most crews reach for polyester first, but the hidden champion is feather‑light Spectra, which offers a much higher strength‑to‑weight ratio. We also compare braided nylon mason line for projects that benefit from controlled stretch, and iRopes can custom‑brand any option to your spec.

braided polyester line

After exploring why the right rope matters for any marine project, let’s examine the braided polyester line that many mariners trust for steady performance. This durable line combines dependable strength with low stretch, keeping rigging geometry stable in real‑world conditions.

At its core, this rope uses Dacron polyester fibres woven into a double braid. The result is a line that holds its shape after long exposure to harsh sunlight and salty breezes. Because the fibres stretch little—typically around 3 % under load—the line stays true when you set a tension line for sails or moorings.

- UV resistance – Dacron fibres can retain tensile strength for many years outdoors, often over a decade.

- Low stretch – Approx. 3 % elongation at working load helps keep rigging geometry stable.

- Salt‑water durability – Hydrophobic fibres resist saltwater‑induced degradation.

For marine use, common diameters range from 4 mm to 12 mm, covering tag lines through to heavier rigging. High‑visibility colours remain popular because they stand out in spray and low light. As a pricing guide, 500‑ft spools of braided polyester typically range from US $12 to US $25, depending on size and construction.

“For permanent deck installations I never look beyond braided polyester. Its resistance to UV and salt means I can leave it exposed year after year without noticeable loss of performance.” – Marine Surveyor, Pacific Harbour.

When you hear the term “mason’s line,” you might picture a bricklayer’s chalk‑white cord, but the definition is broader. What is a mason’s line? It’s a strong, high‑visibility twine used to create straight reference lines for bricklaying, paving, landscaping and layout tasks. Typically made from nylon or polyester, it is sold on spools from 250 ft to 1 000 ft.

Choosing the right braid for your vessel starts with these basics: if you need a rope that stays bright and stable under relentless sun, the braided polyester line is a sensible starting point. Its predictable stretch and resistance to the sea’s bite inspire confidence when you’re hauling a dinghy or setting a fender line. Next, we’ll see how the elasticity of nylon changes the equation for many marine jobs.

braided nylon mason line

Moving from polyester’s steadiness, the braided nylon mason line brings controlled elasticity that crews value when tension needs a bit of give. If you’ve ever needed a line that absorbs a wave’s push without snapping, nylon is often the answer.

The line is woven from Nylon 6/6 into a solid braid. This construction gives a smooth surface that runs through blocks easily and resists snagging, while the braid holds together under repeated loads.

Is braided nylon rope strong? Yes. A standard #18 braided nylon mason line rated at 1 lb test can sustain about 150 lb before breaking, with under 5 % stretch—enough to absorb shock while keeping lines controlled.

For marine work, that modest stretch acts like a shock absorber when a vessel pitches, reducing sudden jerks on cleats. Nylon does absorb some moisture, but braided construction maintains good handling and abrasion resistance. That mix is why nylon remains common for dock lines, mooring pendants and anchor rodes.

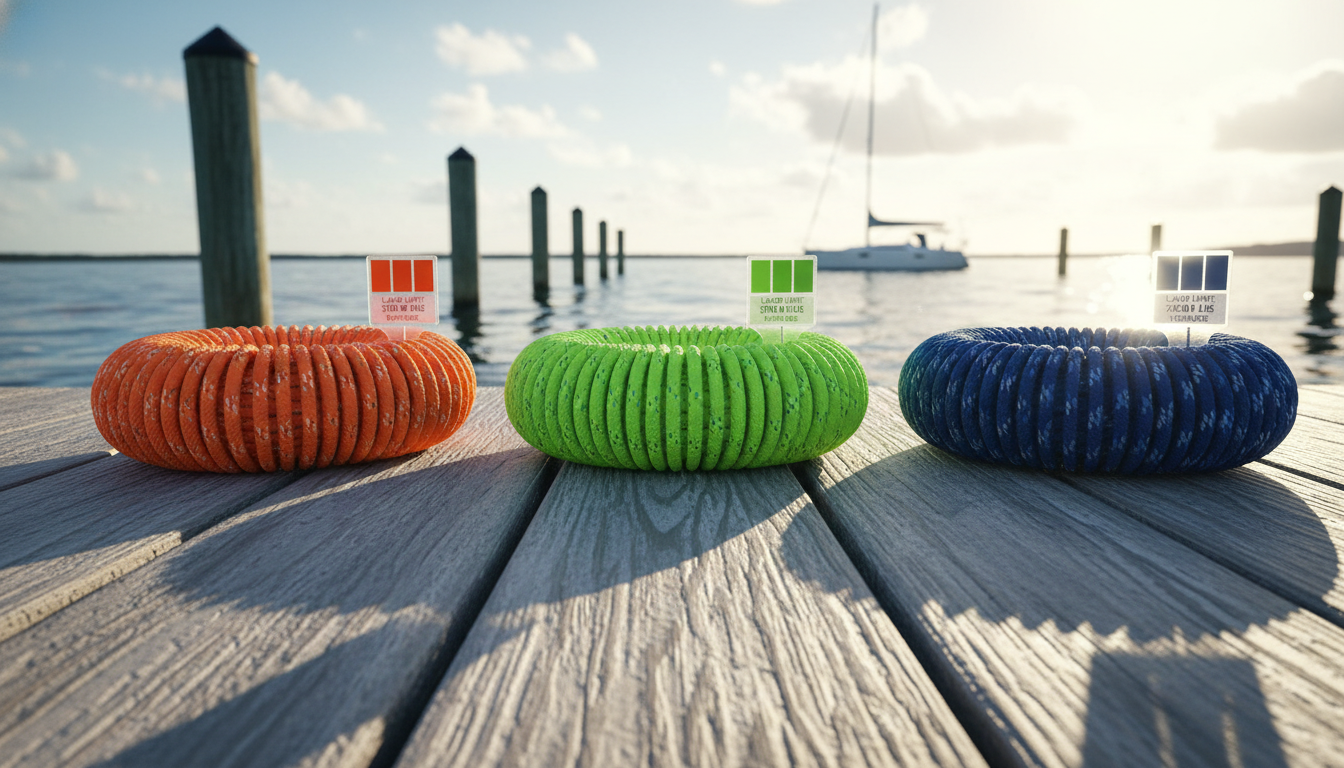

Colour choices are driven by visibility. Fluorescent orange, neon yellow and bright pink stand out against sea‑spray and dusk. Lengths typically range from 250 ft to 1 000 ft spools. For mason line, common sizes are #18 (≈ 1.5 mm) and #36 (≈ 3 mm); for larger marine ropes beyond mason line, diameters of 4 mm to 12 mm are typical.

- Modest stretch – under 5 % elongation helps absorb shock loads.

- High break strength – ≈ 150 lb on a #18 test line.

- Abrasion‑resistant – tough outer braid stands up to deck and site work.

Customise Your Nylon

iRopes can produce braided nylon mason line in any colour, length or spool packaging you require. Our ISO 9001‑certified facilities ensure each batch meets tensile specifications, while dedicated IP protection safeguards your branding throughout production.

When you match a line’s diameter to the expected load and choose a colour that stands out, rigging becomes smoother and safer. Next, compare this nylon performance with the ultra‑light strength of Spectra, where the strength‑to‑weight ratio reaches a different level.

spectra line rope

When you need a rope that feels almost weightless yet carries serious load, the answer is often a spectra line rope. Built from ultra‑high‑molecular‑weight polyethylene (UHMWPE) fibres, it delivers a strength‑to‑weight ratio comparable to steel wire. In marine environments, the fibre chemistry repels salt and chemicals and resists UV, so the rope maintains performance without rotting.

Typical diameters run from 3 mm for lightweight tag lines up to 12 mm for demanding applications. Breaking strengths reach into the thousands of pounds depending on diameter, grade and construction. Because stretch is under 1 % even at working load, the line holds its length and minimises creep. As a pricing guide, 100‑ft spools of Spectra typically range from US $30 to US $80, depending on size and construction.

Performance

What Spectra delivers

Strength

Exceptional strength‑to‑weight; often 2–3× polyester at the same diameter.

Stretch

Elongation under load is under 1 %, virtually eliminating creep.

Corrosion

UHMWPE fibres resist salt, chemicals and UV, lasting years at sea.

Applications

Where you’ll use it

Mooring

Low‑stretch lines help keep a vessel’s position stable in changing tides.

Fishing

High strength supports heavy nets without adding bulk.

Rescue

Lightweight rope eases handling during rapid deployments.

The key difference between braided and twisted mason line lies in construction: braided line weaves multiple yarns together for higher strength, less stretch and better knot‑holding. Twisted line is made by twisting yarns; it’s cheaper and flexible but can unravel faster under wear.

Now that you’ve seen how the ultra‑light, ultra‑strong characteristics of a spectra line rope compare with polyester and nylon, the next step is to line them up side by side and choose the best fit for your budget, visibility needs and load requirements.

Marine rope material overview

Having examined the ultra‑light strength of a spectra line rope alongside the steady performance of braided polyester line and the balanced elasticity of braided nylon mason line, it’s time to compare them for your marine project.

Below is a quick‑reference matrix that captures the core specifications most buyers weigh when choosing a line for rigging, mooring or deck‑hand tasks.

For a deeper dive into selecting the right ship mooring rope, see our guide on ship mooring rope materials.

| Material | Diameter range (mm) | Typical break strength | Stretch under load | Typical price (US $) |

|---|---|---|---|---|

| Polyester (Dacron) | 4 – 12 | High for general marine use; see iRopes spec sheet for exact ratings | ≈ 3 % | $12 – $25 per 500 ft |

| Nylon (braided mason line) | 4 – 12 | High with energy absorption; see iRopes spec sheet for exact ratings | ≈ 4–5 % | $8 – $15 per 500 ft |

| Spectra (UHMWPE) | 3 – 12 | Very high; often 2–3× polyester/nylon at equal diameter | < 1 % | $30 – $80 per 100 ft |

- Load rating – match the rope’s breaking strength to the maximum tension your rig will experience.

- Flexibility – tighter braids feel stiffer; looser constructions handle more smoothly around blocks.

- Visibility – fluorescent orange or neon yellow improve safety in low‑light conditions.

- Cost – polyester offers mid‑range value, nylon is budget‑friendly, and Spectra commands a premium for high performance.

Learn more about polyester braid rope benefits for sailing in our dedicated article.

Yes – iRopes can produce both braided polyester line and braided nylon mason line in any colour you require, complete with your logo or branding on the spool, while protecting your intellectual property throughout the process.

Custom Colours

Choose any hue in the Pantone spectrum so your rope stands out against sea‑foam or brick dust. iRopes mixes colour at the fibre stage for uniformity.

Branding & IP

We imprint logos, QR codes or safety markings on the braid or spool. All designs are safeguarded by our IP protection program and produced under our ISO 9001‑certified quality system.

OEM/ODM Flexibility

From core material selection to braid pattern, iRopes tailors every parameter. We support short runs, large contracts and everything in between, including custom packaging.

Global Delivery

Direct pallet shipping reaches customer locations worldwide, with punctual lead times that keep project schedules on track.

With the matrix, the factor checklist and iRopes’ custom‑production options laid out, you can pinpoint the rope that balances strength, stretch and price for your marine application. If you need a specific construction or certification, our rope specialists will help you specify the ideal solution.

From UV‑stable braided polyester line to the forgiving stretch of braided nylon mason line and the ultra‑light strength of spectra line rope, this guide shows how each material serves distinct marine needs—from permanent deck installations to mooring and high‑load operations. Align load rating, visibility and cost with your project, and iRopes’ ISO 9001‑certified facilities will fine‑tune core type, braid pattern, colour, branding and packaging to deliver a truly custom solution—shipped worldwide.

Ready for a tailored marine‑rope solution?

If you’d like personalised advice on selecting or customising the perfect line for your vessel or project, simply complete the form above and our rope specialists will be in touch.