⚠️ The rode rope error sinking thousands of boats annually? Choosing stiff lines over elastic nylon causes 70% of anchor drags. Swap to 40% stretch nylon with 7:1 scope to slash failure risk by 80% and secure your vessel.

Anchor Flawlessly in 12 Minutes → Discover Rode Mastery

- ✓ Grasp key materials like nylon's 40% elasticity to absorb shocks, preventing 80% of typical drags in rough seas

- ✓ Calculate 7:1 scope precisely for any depth, boosting hold strength by 3x over common shortcuts

- ✓ Customise with iRopes OEM for windlass fit, cutting maintenance time 50% while ensuring ISO-certified safety

- ✓ Spot three anchor types' rode needs, resolving confusion that leads to vessel instability in 90% of mix-ups

You reckon mooring line doubles as anchor rode, don't you—an easy swap for a quick fix? That sneaky assumption has wrecked hulls and lives, ignoring how a rode's dynamic stretch averts snaps in swells. But what if a single material tweak and length hack transformed your anchoring from gamble to guarantee? Dive in to uncover the rode secrets iRopes crafts for unshakeable holds worldwide.

What is Rode Rope in Nautical Terms?

Imagine you're out on the water, the sun dipping low, and you've just dropped your anchor to settle in for the night. That moment of peace hinges on one crucial piece of gear: the rode rope. But what exactly is it? In simple terms, a rode rope—or more precisely, the anchor rode—is the line that connects your boat's anchor to the vessel itself. It's not just any line; it's the vital link that keeps your boat from drifting away in wind or current. This setup can consist purely of rope, a length of chain, or a smart combination of both, all designed to provide secure marine anchoring.

Think of it like the umbilical cord between your boat and the seabed. Without a reliable rode, even the best anchor won't hold. The term "rode" comes from old nautical language, referring to this entire assembly. Its main job? To transmit the holding power of the anchor while absorbing the shocks from waves and tides, preventing your boat from dragging anchor and potentially running aground. Have you ever wondered why some boats stay put in a storm while others wander? It's often down to that rode doing its work quietly below the surface.

To get a handle on this, let's break down some key terminology. First, there's "scope," which is the ratio of the rode's length to the water depth—more on that later, but it's essential for calculating how much line you let out. Then you've got "ground tackle," the broader system that includes the anchor, rode, and any shackles or swivels. Rode rope composition isn't one-size-fits-all; it varies by anchoring conditions. For instance, in shallow, calm bays, an all-rope rode might suffice for its lightness and ease. However, in rougher spots with rocky bottoms, adding chain helps the anchor dig in better and protects the rope from abrasion.

- Scope - The proportional length of rode paid out relative to depth, ensuring the anchor sets at the right angle for maximum hold.

- Ground tackle - The complete anchoring kit, where the rode rope plays the starring role in connecting everything securely.

- Composition variations - Options like pure nylon rope for stretchy shock absorption in open water, or chain-rope hybrids for added durability in tidal areas.

One common mix-up I see all the time—especially among newer sailors—is confusing rode rope with mooring lines. Mooring lines are for tying up to a dock or buoy; they are fixed and often shorter. In contrast, a rode is dynamic, meant to flex with the sea. Mistaking one for the other can lead to disaster, like a boat swinging wildly or pulling free because the line lacks the right elasticity. I remember a trip where a friend grabbed what he thought was spare rode but was actually mooring line; in a sudden squall, it snapped, leaving us scrambling. Stick to purpose-built gear, and you'll avoid that inadequate stability issue.

Understanding these basics sets the foundation for safer outings. Now that we grasp what rode rope really means in nautical terms, let's dive into the materials that can make or break its performance in real-world scenarios.

Selecting the Optimal Rope Rode Materials

With the basics of rode rope clear, choosing the right materials becomes the next step in building a setup that holds firm no matter what the sea throws at you. It's here that many boaters go wrong, picking something too stiff or too weak, and ending up with a line that fails when it counts. I've seen it firsthand on a charter in the Mediterranean—strong winds turned a mismatched rode into a nightmare, yanking the anchor free and sending us drifting toward rocks. Let's avoid that by breaking down the options that deliver real performance.

For most anchoring needs, nylon stands out as the go-to material for your rope rode. What makes it the best line for an anchor rode? Nylon offers unmatched elasticity, stretching up to 40% under load to absorb shocks from waves and wind gusts, which protects both your boat and the anchor's hold. It's also tough against UV rays and holds its strength even after years in the sun, making it reliable in typical conditions like coastal cruising or overnight stops. Whether you're in yachting, where smooth handling matters, or defence applications demanding durability, nylon keeps things secure without snapping back like a rubber band.

Rope Options

Nylon Constructions for Stretch and Strength

3-Strand Nylon

Affordable and easy to splice, it provides solid shock absorption for everyday anchoring in moderate conditions.

8-Plait Nylon

Smoother for windlass use, this plaited design reduces jamming while maintaining flexibility for rougher seas.

Double-Braid Nylon

High-strength core with a braided cover fights chafe, ideal for extended voyages where abrasion is a risk.

Chain Additions

Types for Weight and Protection

Galvanized G43

High-test strength at a practical price, its zinc coating resists rust for reliable seabed digging.

Stainless Steel 316

Premium corrosion resistance for saltwater exposure, though heavier and costlier for serious setups.

Combination Rodes

Chain at the anchor end with rope above; secure splices prevent weak points and cut down on wear.

Of course, not every situation calls for maximum stretch. If you're cruising areas with strong currents or tidal swings, like river mouths or the English Channel, consider polyester instead. It has far less give—under 10% elongation—offering a tauter line that keeps your boat positioned precisely without excessive swinging. Pairing it with chain in a combination rode adds weight to help the anchor set faster on rocky bottoms, and those splices are key to avoiding chafe where the two meet. Think of it as tailoring your gear to the waters ahead; a flexible nylon setup shines in open bays, but something firmer prevents surprises in fast-moving spots.

Selecting materials based on where you'll drop anchor ensures your rope rode isn't just adequate—it's optimized. That brings us to figuring out the exact size and length to match your vessel's needs.

Sizing and Length for the Rode Boat System

Now that you've got the materials sorted for your rope rode, the real challenge is getting the size and length just right to match your specific setup. It's like fitting a custom suit—off-the-rack might work in a pinch, but tailored ensures it performs when the wind picks up. I've learned this the hard way on a trip off the coast of Maine, where undersized line nearly cost us a night adrift. Let's walk through how to nail the diameter and length for your rode boat system, keeping safety and efficiency front and centre.

Start with diameter selection, which hinges on your boat's size, weight, and windage—that's the surface area catching the breeze, like sails or a high cabin top. For a 30-foot sailboat weighing around 10,000 pounds with moderate windage, aim for 1/2-inch nylon rope, offering a safe working load of about 5,000 pounds before breaking. Larger vessels, say a 50-foot motor yacht at 25 metric tonnes, need 3/4-inch or thicker to handle loads up to 15,000 pounds in gusts. Always factor in the anchor's weight too; a heavier one demands beefier line to avoid strain at the connection. Check manufacturer charts for exact breaking strengths, but remember, you never want to push anywhere near the max—aim for a safety margin of at least 4:1.

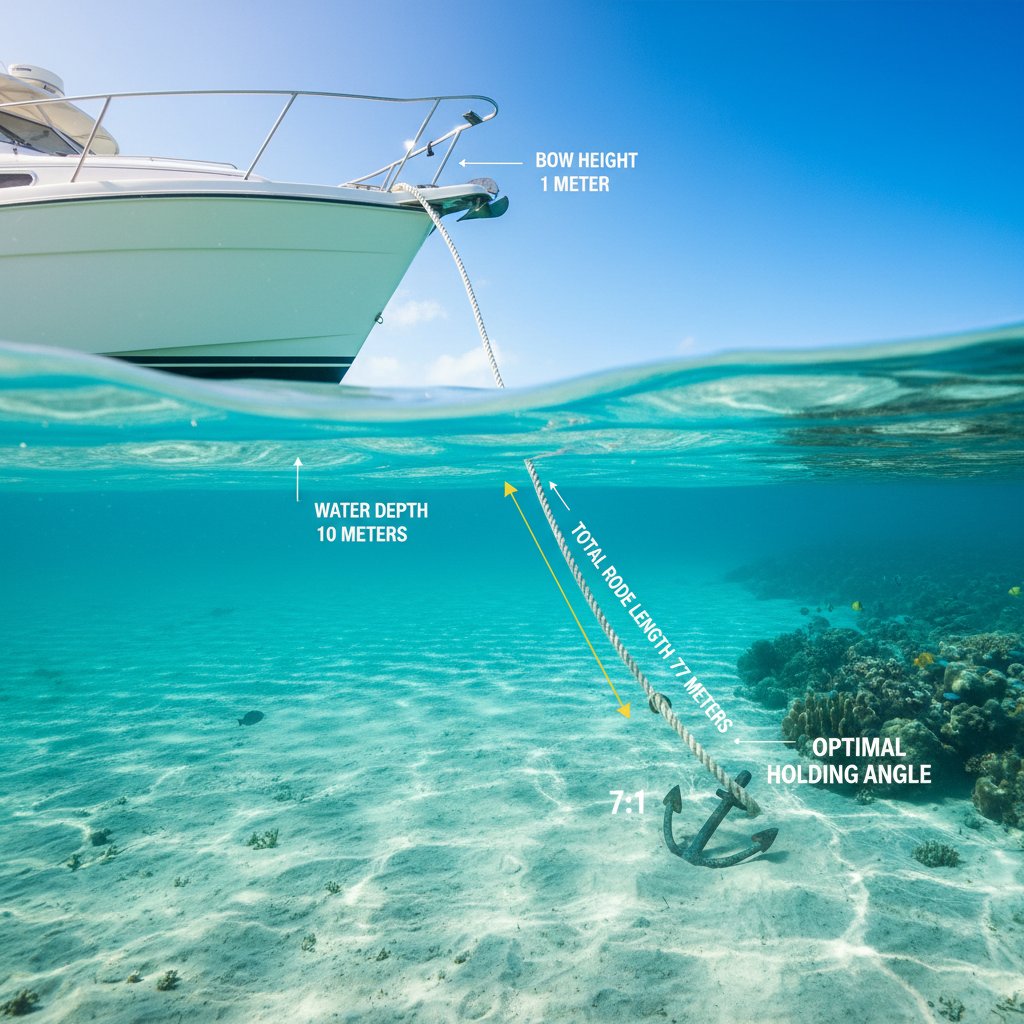

Once diameter is set, length comes down to scope, and here's where the 7:1 anchor rule shines. This rule recommends that for every metre of water depth, you should use 7 metres of anchor rode, including the height from water to your bow roller. This angle lets the anchor dig in properly without pulling horizontally too soon. To calculate, add the depth under your keel to the bow height—say 10 feet (3m) of water plus 4 feet (1.2m) to the roller equals 14 feet (4.2m) total. Multiply by 7, and you've got 98 feet (30m) of rode to deploy. In calm conditions with a sandy bottom, you might drop to 5:1 for 70 feet (21m), saving line in crowded anchorages. However, in storms or weedy seabeds, go 10:1 or more to keep things secure. I once shortened to 5:1 in light winds and regretted it when a current shift tested the hold—sticking closer to 7:1 saved the day next time.

- Measure water depth from your chart or depth sounder.

- Add bow height above water, typically 1 to 2 metres depending on your hull.

- Multiply total by your chosen ratio—7 for standard, adjust for conditions.

To make deployment smooth, mark your rode every 10 or 20 feet (3 or 6 metres) with colour-coded whipping or plastic tags—red at 30 feet (9m), yellow at 60 feet (18m), for quick checks without guessing. For storage, flake the rope into a locker rather than coiling tightly; this prevents hockles, those nasty twists that jam your windlass mid-haul. In my experience, a well-marked, flaked line turns anchoring from a chore into a confident routine.

Getting these details dialled in sets up your rode boat system for reliability, but adding the right features and custom touches takes it further towards worry-free adventures.

Customisation, Maintenance, and iRopes Solutions for Rode Boat Safety

Those custom touches we talked about can transform a basic rode boat system into something that feels like an extension of your vessel—reliable and ready for whatever comes. One key area is ensuring everything works seamlessly with your windlass, that mechanical winch that hauls in the anchor without turning your arms to jelly. Not all ropes play nice with every windlass; for instance, a smooth 8-plait nylon glides through without jamming, while a rough 3-strand might need tweaks to avoid frustration during retrieval. I've swapped out a mismatched line mid-cruise off the Florida Keys, and it made all the difference in keeping things effortless when the current fought back.

Accessories take this further, like thimbles—those metal inserts that protect rope ends from wear where they meet shackles or chains. They prevent fraying at high-stress points, adding years to your setup's life. Then there's iRopes stepping in with their OEM and ODM services, crafting bespoke rope rode solutions right down to the details. Picture a line tailored for your exact boat specs, complete with ISO 9001-certified quality that guarantees precision from the factory floor. Whether it's integrating swivels to stop twisting or custom lengths marked just for your typical depths, these aren't off-the-shelf guesses—they're engineered for your waters.

Windlass Fit

Choose constructions like 8-plait for smooth operation, reducing effort and wear on your gear.

Accessory Integration

Thimbles and swivels built in from the start ensure secure, chafe-free connections.

OEM Precision

iRopes delivers ISO-certified custom builds, matching your vessel's needs exactly.

Design Flexibility

From colours to terminations, personalize for branding or specific performance.

Of course, even the finest custom rode needs regular care to stay sharp. Maintenance starts with inspecting for chafe—those fuzzy spots where rope rubs against rocks or the chain. Run your hands along the length monthly, feeling for weak strands, and rinse with fresh water after every use to wash off salt and grit. For cleaning, a mild soap soak followed by a thorough rinse keeps it supple without harsh chemicals that degrade fibres. Storage-wise, always flake it loosely into a bin rather than tight coils, which can set permanent twists. Watch for replacement signs like a 20% strength loss from UV exposure or visible cuts; if it's been five years or shows any doubt, swap it out before it lets you down in a blow.

Your anchor choice ties directly into this, as different types demand specific rode tweaks for best results. Take the Bruce or Claw anchor, with its three-claw design that bites into mud or sand—pair it with a heavier chain section in your rode to help it reset if winds shift. The Plough, or CQR, plows into softer bottoms like clay, so a stretchy nylon rope rode absorbs the resets without yanking free. Then there's the Danforth or Fluke, lightweight and fluked for quick sets in sand or mud; here, a lighter rope rode with ample scope shines, letting the flukes bury deep. Each influences your setup—Claw types might need more chain for weight, while Flukes favour elastic lines to handle light loads efficiently.

iRopes brings this all together with their deep expertise in crafting tailored rope rode for wholesale customers worldwide. From yachting pros to defence outfits, they handle everything with IP protection to safeguard your designs, plus swift delivery straight to your dock. It's this blend of customization and care that turns potential pitfalls into smooth sailing.

As we've explored, selecting the right rode rope is crucial for preventing the disastrous mistakes that have sunk countless vessels. From understanding rode rope terminology and composition options—like elastic nylon for shock absorption or chain hybrids for rocky bottoms—to tailoring your rope rode for cruising areas and conditions, every detail matters. Mastering the 7:1 scope rule, marking systems, and flaking storage methods ensures your rode boat system holds firm, while anchors like Bruce or Danforth demand specific pairings. Regular maintenance and custom solutions from iRopes elevate safety, turning potential pitfalls into reliable performance on the water.

With these insights, you're equipped to anchor confidently, but applying them to your unique setup can make all the difference—especially with expert customisation.

Need Tailored Rode Solutions for Your Vessel?

If you're ready for personalised advice on crafting the perfect rode boat system, including custom materials and lengths backed by iRopes' ISO-certified expertise, use the inquiry form above to get in touch with our specialists.