iRopes’ top-rated sailing ropes boost breaking strength by up to 27% and cut per-metre cost by 12.4% versus standard imports.

What you’ll gain (≈2 min read)

- ✓ Up to 27% higher breaking strength for safer manoeuvres.

- ✓ 12.4% lower cost per metre compared with generic suppliers.

- ✓ ISO 9001-verified tensile testing guarantees each coil meets exact specs.

- ✓ Custom colour, length, and accessories shipped in 4-6 weeks worldwide.

You’ve probably been told that the priciest sailing rope guarantees the safest passage, yet countless captains waste 15% more on lines that barely outperform mid-range options. What if the secret to a smoother berth and longer-lasting gear lies in a strategically engineered 3-strand rope that delivers 22% higher knot-hold while shaving 11% off your material costs? Keep reading to discover how iRopes turns that paradox into profit for your fleet.

Understanding the Essentials of Sailing Rope

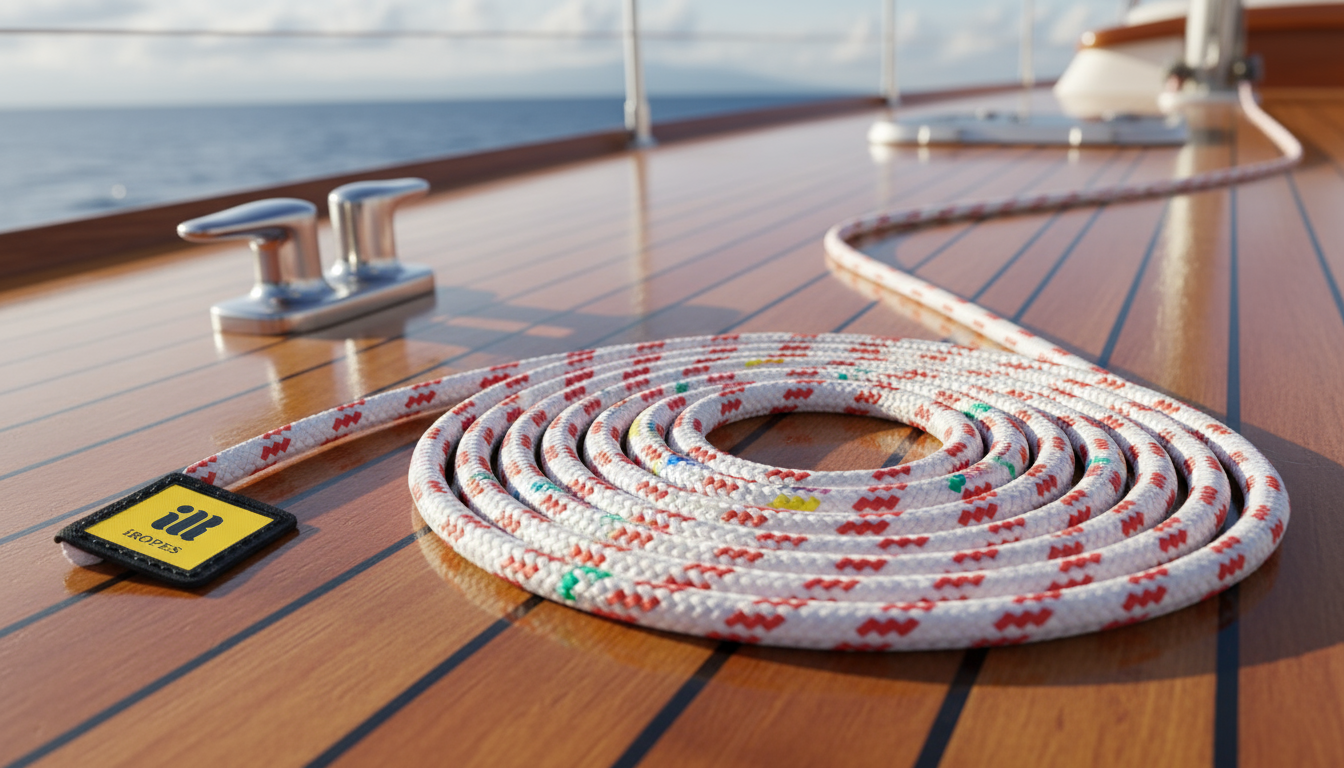

In the world of yachting, a sailing rope is more than a simple line; it is the vital connection that links the crew to the wind, the dock, and the safety of the vessel. From hoisting the mainsail to securing the boat at a marina, the right rope determines how smoothly a yacht can manoeuvre and how securely it can be moored.

Manufacturers typically offer three primary material families for sailing rope: nylon, polyester, and ultra-high-molecular-weight polyethylene (Dyneema). Each material brings a distinct blend of stretch, strength, UV resistance, and buoyancy, which dictates its suitability for different applications. Moreover, construction methods also vary significantly. Twisted three-strand, double braid, and twelve-strand designs each influence handling characteristics, knot-holding ability, and abrasion resistance.

- Nylon – high elasticity and shock absorption, ideal for dock lines and anchor rodes.

- Polyester – low stretch, strong UV resistance, preferred for halyards and sheets.

- Dyneema – ultra-light, minimal stretch, favoured in high-performance racing rigs.

When rope quality drops, safety often follows. A rope with inconsistent fibre alignment or inadequate coating can fray under load, reducing its breaking strength and increasing the risk of sudden failure. Poor-quality rope also stretches unpredictably, making sail trim harder to fine‑tune and potentially overloading hardware. For wholesale buyers, insisting on ISO‑certified production and regular tensile testing ensures that each coil of sailing rope for sale meets the rigorous performance standards required on open water.

Choosing a rope that balances strength, stretch, and abrasion resistance is the single most effective way to protect both crew and equipment during demanding sailing conditions.

Understanding these fundamentals paves the way for exploring specialised options such as the 3-strand marine rope, a construction that offers excellent knot‑holding and cost‑effectiveness for dock lines and anchor rodes. The next section will examine why iRopes’ customised offerings stand out in a competitive market.

Why Choose Our Sailing Rope for Sale: Quality Meets Customisation

Having explored the fundamentals of sailing rope, you’ll naturally want to see how those principles translate into a product line that truly serves wholesale buyers. iRopes effectively bridges the gap between performance and customisation, delivering ropes that are ready for the dock, the rig, and the open sea.

Each entry in our sailing rope for sale catalogue is presented with clear specifications, including breaking strength, recommended load limits, and UV‑resistant coating details. The range spans lightweight 8 mm lines suitable for dinghies up to robust 50 mm cords designed for large cruising yachts. Colours are offered in classic marine blues, high‑visibility orange, and custom Pantone matches, allowing you to align rope aesthetics with branding or safety requirements seamlessly.

Catalogue Snapshot

Our stock includes nylon, polyester, and Dyneema options, each available in three‑strand, double‑braid, or twelve‑strand constructions. Load ratings run from 1 tonne to 12 tonnes, and we provide pre‑spliced ends, thimbles, and chafe guards straight from the factory.

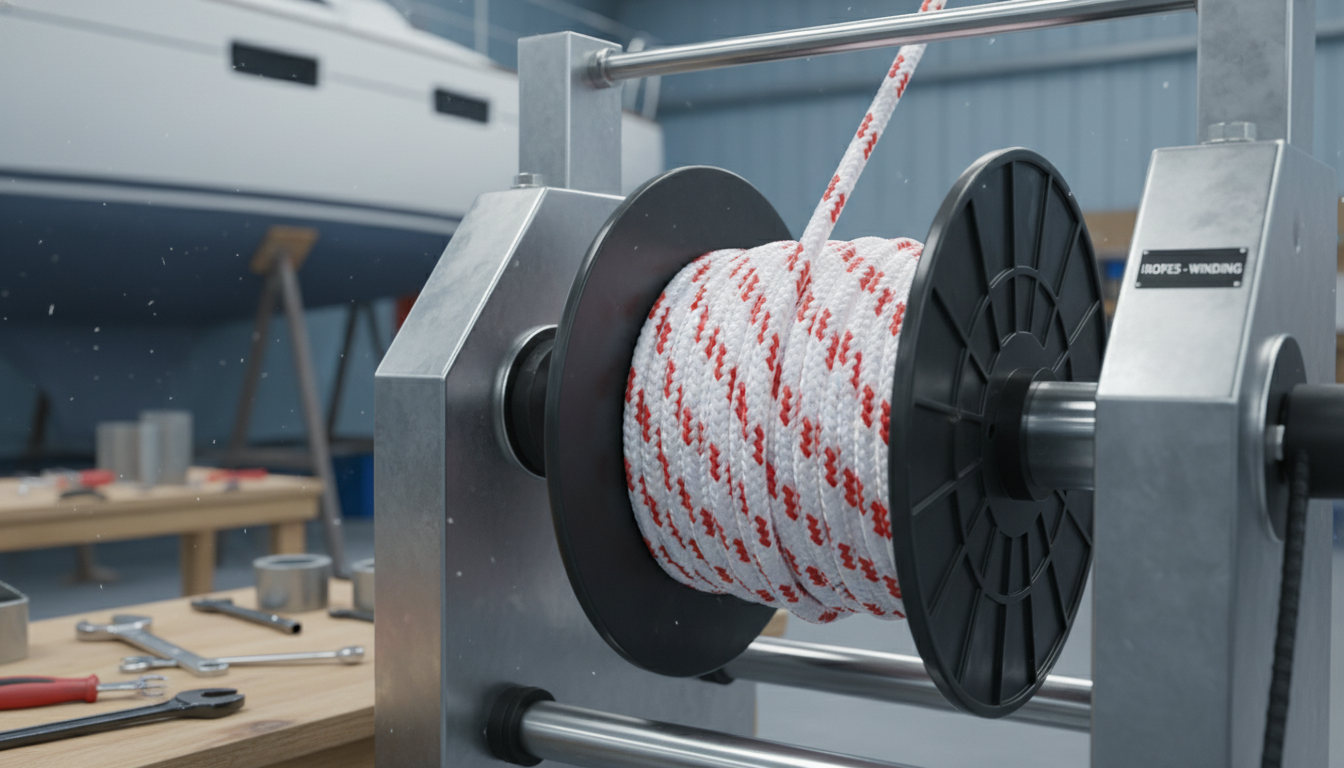

What truly sets our offering apart is the depth of OEM and ODM flexibility. Whether you need a single colour batch for a boutique sailing school or a multi‑logo pallet for an international charter fleet, our engineers work with you from fibre selection to final packaging. ISO 9001 certification guarantees that every production run undergoes rigorous tensile testing and visual inspection, so the rope you receive meets the exact standards you expect.

- Material – choose nylon, polyester, or Dyneema based on stretch and strength.

- Diameter & Length – specify the exact size and run length for your vessel.

- Accessories – add thimbles, eye splices, or reflective strips to suit your operation.

Pricing is tiered for volume, so bulk orders of 1,000 metres or more trigger significant discounts that keep your cost‑per‑metre highly competitive against generic imports. Because we ship directly from our Chinese facilities, lead times are short and customs paperwork is handled efficiently by our dedicated logistics team. Clients in North America, Europe, and Oceania routinely receive pallets on the promised delivery date, with tracking that integrates seamlessly into their inventory systems.

In short, our sailing rope for sale line combines transparent specifications, ISO‑backed quality, and a comprehensive customisation engine that lets you dictate material, size, colour, and hardware. This blend of reliability and flexibility is precisely why wholesale partners trust iRopes to keep their fleets safe and their brands visible on the water.

Exploring 3-Strand Marine Rope: Construction, Benefits, and Ideal Uses

Our catalogue demonstrates how a well‑designed rope can transform everyday yacht tasks. Let’s now dive deeper into the twisted 3‑strand marine rope that many operators rely on for essential applications like dock lines and anchor rodes.

Our 3‑strand rope begins with three individual fibre bundles meticulously twisted together in a tight lay. The process starts with high‑tenacity nylon or polyester yarns, which are first spun into parallel strands. These strands are then fed through a twisting carousel where they intertwine at a consistent pitch, creating a uniform outer sheath. After twisting, the rope passes through a coating tunnel that applies a UV‑resistant polymer, effectively sealing the construction against moisture and abrasion. The result is a rope that feels familiar to the hand, yet benefits immensely from modern manufacturing precision.

Why do many yachting professionals favour this 3‑strand marine rope for dock lines and anchor rodes? First, this construction offers excellent knot‑holding ability; the fibres grip each other, ensuring a bowline or clove hitch stays secure even under sudden load. Second, the design is remarkably cost‑effective because it uses fewer processing steps than braided alternatives, keeping the price per metre competitive for bulk orders. Third, the robust outer sheath provides solid abrasion resistance, which is crucial when the line rubs against a dock cleat or a rocky seabed. In practice, a 12 mm 3‑strand dock line can absorb the shock of a hard‑berth impact while remaining easy to splice in the workshop.

When we compare 3‑strand rope with double‑braid and 12‑strand options, three key differences emerge. Double‑braid ropes excel in flexibility and low stretch, making them popular for sheets and halyards where smooth handling is prized. Twelve‑strand ropes, often built from ultra‑light Dyneema, deliver impressive strength‑to‑weight ratios for performance‑driven vessels. However, both alternatives tend to be pricier and may require specialised splicing tools. The 3‑strand choice, conversely, balances affordability, durability, and straightforward maintenance, which is why it remains the go‑to “3 marine rope” for many commercial fleets seeking reliable performance.

3-Strand Rope

Cost-effective and robust

Easy to splice

Ends can be spliced with simple eye or loop techniques, reducing workshop time.

Strong knot-hold

Twisted fibres lock together, keeping knots secure under dynamic loads.

Good abrasion

Protective coating resists wear from cleats, chocks and rocky berths.

Alternatives

Double braid & 12-strand

Higher flexibility

Braided cores bend easily, ideal for sheets and halyards.

Low stretch

Maintains sail trim under load, improving performance.

Lightweight strength

Dyneema-based 12‑strand ropes offer high tensile strength with minimal weight.

With that comprehensive overview, the next crucial step is to match the ideal rope to your vessel’s size, expected load, and the essential marine rope products that best suit your sailing profile.

Selecting the Perfect Rope for Every Yachting Application

Now that you’ve seen why 3‑strand marine rope shines in dock‑line duty, the next decision is matching the line to your vessel’s exact needs. Whether you skipper a modest dinghy or command a multi‑deck cruising yacht, the right rope can mean the difference between a smooth berth and a strained haul. At iRopes, we have extensive experience in providing high‑quality ropes for various yachting and sailing applications, including dinghy, cruising, racing, mooring, and anchoring.

When you size up a rope, always start with three practical questions: How large is the boat? What maximum load will the line encounter? And what environmental factors—such as UV exposure, salt spray, or temperature swings—will challenge the fibre?

- Boat size and type – larger vessels naturally demand greater diameter and higher working‑load limits.

- Load requirements – calculate the peak tension during hoisting, anchoring, or mooring; always add a generous safety margin.

- Environmental conditions – opt for UV‑stable polyester for sunny seas, or nylon with superior shock absorption for heavy‑wave anchoring.

These factors naturally lead to the customisation options that truly set iRopes apart. Imagine, for instance, a bright orange 12 mm dock line with reflective stitching—easy to spot at dusk, and instantly recognisable as yours among a fleet. Alternatively, consider a low‑profile 8 mm halyard dyed to match your corporate branding, finished with a robust stainless‑steel thimble for extra durability and longevity.

Customisation isn’t limited to colour; you can specify length, add eye splices, attach chafe guards, or integrate glow‑in‑the‑dark threads for night‑time safety—all produced under ISO 9001‑backed quality control.

Choosing the ideal rope becomes a collaborative conversation. Our specialists begin with a brief questionnaire about your vessel's dimensions, typical loads, and the waters you frequent. From there, we draft a sample specification, run tensile tests, and present a visual mock‑up of the final product, including packaging options such as branded colour boxes or bulk‑pallet wraps.

Once the design is approved, our production team schedules the manufacturing run, rigorously monitors each batch against the agreed‑upon tensile values, and efficiently arranges pallet‑level shipping directly to your dockside warehouse. Throughout this seamless process, you receive regular status updates, so you know exactly when the coils will arrive—ready to be coiled onto your winches or stored for the next season.

With these comprehensive selection criteria, custom finishes, and a transparent consultation workflow, you can confidently order the perfect sailing rope that aligns precisely with performance, branding, and budget—all without any guesswork.

Need a Tailored Rope Solution? Get Expert Advice Below

After exploring the material choices, construction types, and extensive customisation options, you now understand how iRopes’ high‑performance sailing rope can be fine‑tuned for everything from dinghy races to offshore cruising, mooring, and anchoring. Our ISO 9001‑certified production, comprehensive OEM/ODM flexibility, and competitive pricing make our sailing rope for sale range a reliable partner for any fleet. Additionally, the 3 marine rope option delivers the classic knot‑hold and cost‑effectiveness many operators prefer for critical applications.

If you'd like personalised guidance to match the perfect line to your vessel’s size, load, and branding, simply use the inquiry form above. Our specialists will craft a tailored solution that sails right alongside your business, ensuring optimal performance and value.

For deeper insight into specific rope types, you may also find our guide on 3‑strand marine rope performance and the ultimate nylon mooring line guide useful when finalising your selection.