⚓ Knots can slash your anchor rope's strength by 20-50% under storm loads—but splicing retains over 90%, turning potential disaster into unbreakable security for your vessel.

In a 12-minute read, unlock these anchoring essentials:

- ✓ Grasp why knots fail in rough seas, cutting strength to just 50% and risking drag

- ✓ Master chain and eye splices for 90%+ rope power, perfect for windlass setups

- ✓ Learn secure knots like the anchor bend for quick, temporary rope-to-anchor ties

- ✓ Select nylon ropes and hardware to prevent chafe, extending your setup's life by 5+ years

You've tied that bowline a hundred times, trusting it to hold your boat steady against the swell—yet under relentless wave shock, it compresses fibres, halving your line's breaking strength. Imagine instead a seamless splice that channels full force through every strand, outlasting tempests without a hitch. What hidden techniques flip the script on failure? And how can custom iRopes solutions anchor your safety for good?

Understanding Your Rope Anchor System

Imagine you're out on the water, the wind picking up, and you need to drop anchor to stay put safely. That's when your rope anchor system—often called the "rode"—becomes your lifeline. Let's break it down simply, because getting these basics right can make all the difference between a peaceful night at sea and a tense ordeal.

The anchor rode consists of three main parts: the anchor itself, the chain, and the rope. The anchor is the business end that digs into the seabed, holding your boat steady against wind and current. It's designed to penetrate sand, mud, or rock, depending on the type—like a plow or fluke anchor. The chain connects directly to the anchor and adds weight to help it set firmly. Then comes the rope, which extends from the chain to your boat, providing the bulk of the length needed for proper scope. Together, they absorb shocks from waves and keep everything secure. Think of it like a team's coordinated effort: the anchor grabs, the chain directs the pull horizontally for better hold, and the rope stretches to handle sudden jerks.

- Anchor - Grips the seabed to prevent drifting, with designs optimised for different bottoms.

- Chain - Lies flat on the bottom, keeping the anchor's pull low and reducing upward strain.

- Rope - Offers elasticity to cushion boat movements, typically nylon for its give under load.

Now, why bother with chain in your rope anchor setup? It isn't just extra weight—it's smart engineering. Chain resists chafe from rocks or coral better than rope alone, which can fray quickly in rough spots. That weight also helps the anchor set faster by keeping the angle low, improving holding power by up to three times compared to all-rope systems. In my early boating days, I skipped enough chain once and watched my anchor drag in a mild current; lesson learned the hard way. Aim for at least a few metres of chain, depending on your boat size—say, 3 to 5 metres for smaller vessels.

Speaking of connections, what links the anchor to the anchor chain? It's usually a sturdy shackle, a U-shaped metal pin that clamps through the anchor's shank and a chain link. For swivel action to prevent twisting, add a swivel fitting between the shackle and chain. These hardware pieces must match your setup's load—galvanised steel for corrosion resistance in saltwater. Secure the shackle pin with a seizing wire or mousing to stop it from unscrewing under vibration.

To make it all work, follow the 7:1 anchor rule for scope—the ratio of rode length to water depth. For every foot of depth, let out seven feet of rode. In 10 feet of water, that's 70 feet total, including chain. This angle keeps the pull horizontal, maximising hold against storms. Adjust for wind or tide, but skimping here risks dragging. Have you ever calculated your scope before dropping anchor? It's a quick habit that builds confidence.

Grasping these fundamentals sets the stage for connecting your components reliably, especially when loads get heavy.

Tying Anchor Rope to Chain: Permanent Splicing Techniques

With those basics in mind, especially under heavy loads, it's time to focus on permanent ways to join your rope to the chain. These methods ensure your setup holds up without the weaknesses that plague knots, giving you peace of mind when the seas turn rough. Splicing, unlike tying, weaves the rope directly into the chain or forms a strong loop, preserving nearly all the line's original power. This is crucial when tying anchor rope to chain.

One standout option is the chain splice, perfect for setups with a windlass since it creates a smooth, low-profile connection that won't snag during retrieval. This technique works best with 3-strand nylon rope, which is common for its flexibility and strength in marine use. You'll need tools like a fid—a tapered tool for threading strands—and some marline for whipping the end. Start by unlaying the rope's strands for about a metre, then carefully insert them through a chain link, alternating over and under to lock in place. Once woven, taper the ends and tuck them back into the rope's core for a seamless finish. I remember my first attempt on a calm dock day; it took patience, but the result felt solid, like the rope and chain were born together.

Another reliable approach is the eye splice with a thimble and shackle. Here, you form a permanent loop in the rope's end, insert a metal thimble to prevent collapse under tension, and secure it to the chain via a shackle. For 3-strand nylon, unravel the end, pass the fid through to create the eye around the thimble, then interlock the strands back into the standing part. The thimble acts as a rigid protector against chafe where the loop rubs. Always use a galvanised or stainless shackle rated for your boat's load, and secure the pin with a cable tie or wire to avoid it working loose from waves. This method shines for easy replacement if damage occurs—just swap the shackle without redoing the whole splice.

- Unlay the rope end and insert fid to form eye around thimble.

- Tuck working strands into the standing part, tapering for smoothness.

- Attach to chain with shackle, securing pin firmly.

What sets splices apart from knots? They retain over 90% of the rope's breaking strength, while knots often drop it to just 20-50% by creating weak points where fibres crush or slip. Under sustained load, like in a storm, knots can tighten unevenly, leading to failure as water and motion exacerbate the stress. Splices distribute force evenly, avoiding that vulnerability.

If you're wondering how to tie an anchor rope to a chain for a lasting bond, splicing is the way to go for permanent setups—it's stronger and more reliable than any knot. For those short on time or expertise, companies like iRopes offer custom pre-spliced ropes, tailored to your specifications with OEM precision and ISO 9001-backed quality. Imagine starting your voyage with a ready-to-deploy line that fits your exact needs.

These enduring joins set a strong foundation, but sometimes you need faster options for direct rope-to-anchor links in a pinch.

Tying Rope to an Anchor: Reliable Knot Methods

While splices provide that unbreakable link between rope and chain for the long haul, there are times when you need a quicker way to secure your line directly to the anchor. Think about setting a secondary hook in a hurry or making an emergency attachment. That's where reliable knots come in, offering temporary strength without the tools or time for splicing. These methods focus on tying rope to an anchor ring or shank, ensuring they hold firm yet release when you need them to. Let's walk through the most trusted options, starting with the one sailors swear by for its balance of security and simplicity.

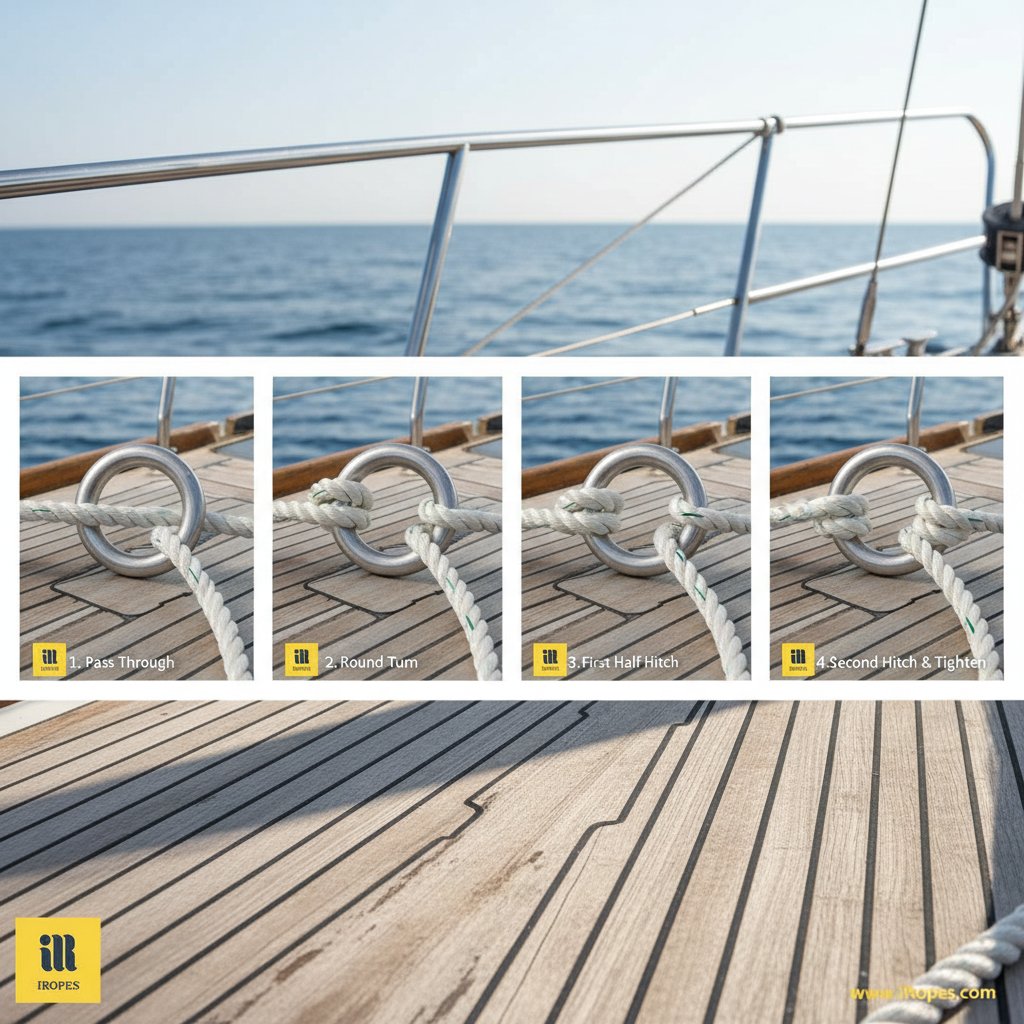

The anchor bend, also known as the anchor hitch, stands out as the gold standard for tying rope to an anchor. It's designed specifically for this job, gripping the ring tightly while allowing easy untying after the strain eases off. To tie it, pass the working end of your rope through the anchor ring, then wrap it around the standing part to form a round turn. Next, make two or three half hitches around the standing part, pulling them snug but not so tight they crush the fibres. Finally, tuck the working end back through the last hitch for extra security. This knot resists slippage under heavy pull, much like how it saved my setup during a sudden squall off the coast—the line held, but I could still untie it without a struggle once calm returned. What makes it shine in rough seas? Its structure jams just enough to lock in place but avoids the over-tightening that dooms lesser knots.

- Thread working end through anchor ring and form a round turn around standing part.

- Wrap working end twice around standing part to create half hitches, tightening each.

- Tuck working end under the final hitch and secure with a half hitch or seizing for backup.

For those versatile moments, like extending your rode or handling a snap change in weather, the round turn and two half hitches offers a solid alternative. Begin with a full round turn around the anchor ring or shank, which bites in immediately for initial hold. Then, pass the working end under the standing part and tie two half hitches on top, cinching them down evenly. It's quicker than the anchor bend and works well on larger rings, though it might need a backup knot in extreme gusts. I've used this one more than once when repositioning gear mid-outing, appreciating how it adjusts without coming undone prematurely.

Don't overlook the bowline when you need a loop for tying rope to an anchor, especially in bridle setups where multiple lines meet at the shank. This knot forms a fixed eye that won't slip under load—start by making a small loop in the standing part, then pass the working end up through it, around the standing part, and back down into the loop. Pull to tighten, ensuring the rabbit ear (the initial loop) stays snug. To avoid slippage, avoid over-twisting the turns and always test the loop under moderate tension before committing. It's ideal for temporary attachments because it unties easily, even after heavy use, but remember to seize the end if waves might loosen it.

If you're searching for how to tie an anchor rope to an anchor, the anchor bend takes the crown for reliability—its design has proven itself through generations of stormy voyages, outlasting flashier options by gripping without binding. These knots give you flexibility on the water, but their performance hinges on the line you choose and the hardware supporting them.

Selecting and Maintaining Rope for Long-Lasting Anchor Performance

Those reliable knots we just covered will only perform as well as the materials they're tied to, so choosing the right rope and hardware is where true durability begins. Picture yourself scanning your gear before a long trip—does your line have the flex to handle a sudden gust without snapping? Getting this selection right means fewer worries when conditions turn.

For anchor setups, nylon stands out as the top choice thanks to its impressive stretch—up to 40% under load—which absorbs shocks from waves and wind like a built-in buffer. This elasticity prevents abrupt jerks that could pull your anchor free or strain the boat. Unlike stiffer polyester, nylon's give makes it ideal for rough waters, though it does absorb water, so plan for a bit of added weight when wet. As for size, match the diameter to your vessel: go with 3/8-inch for boats under 25 feet, stepping up to 5/8-inch for those around 40 feet, and even 3/4-inch for larger ones. These guidelines ensure the line's breaking strength exceeds your setup's demands—say, at least twice the expected load for safety. I once upgraded from a too-thin line on my small cruiser and noticed how much smoother retrievals became—no more frayed edges after a weekend of chop.

Rope Essentials

Key Factors for Anchor Use

Material

Nylon provides vital shock absorption to protect connections during surges.

Diameter

Select based on boat length: 3/8-inch for small craft, up to 3/4-inch for big ones.

Construction

Opt for 3-strand for easy splicing and flexibility in marine environments.

Hardware Choices

Secure Fittings Explained

Shackles

Galvanised steel ones resist corrosion; ensure load rating matches your boat's weight.

Thimbles

These metal inserts protect loops from wear during tying rope to an anchor or chain.

Load Ratings

Choose fittings rated at least 2x your max pull to avoid failures under stress.

To complement your rope, galvanised shackles and thimbles are must-haves for linking components without weak spots. Shackles act like robust clips, passing through chain links or anchor rings, while thimbles keep loops round and chafe-free. Always check their safe working load—typically marked on the side—and pick ones oversized for your setup to handle dynamic forces at sea.

If DIY isn't your style, partnering with a specialist like iRopes can simplify everything. They provide tailored rope anchor solutions through OEM and ODM services, crafting lines with exact diameters, pre-installed splices, and even custom accessories. Backed by ISO 9001 certification, their products ensure precision and reliability, plus full IP protection so your designs stay yours. It's like having a marine engineer on speed dial for wholesale needs, offering specialised performance characteristics and compliance.

Once in place, maintenance keeps it all going strong. Check your rode monthly for signs of chafe—frayed spots where rope rubs against chain or the boat's edge—and inspect shackles for corrosion or loose pins. To prevent rode chafing, wrap vulnerable areas with tubing or use dedicated guards; it's a simple step that extends life by years. Secure every shackle pin with wire or ties to stop vibration from undoing them. Replace the whole system every 5-7 years or after heavy wear, especially if strength drops below 80% of original. Have you given your gear a close look lately? Spotting issues early could save your next outing.

Securing your rope anchor system starts with understanding why knots often fail under load, reducing strength by up to 80%, while splices preserve over 90% for reliable performance at sea. We've explored permanent techniques like chain and eye splices for tying anchor rope to chain, ensuring windlass compatibility and chafe resistance with thimbles and shackles. For temporary needs, the anchor bend excels in tying rope to an anchor, offering secure yet releasable holds alongside alternatives like round turns and bowlines. Opt for nylon ropes sized to your vessel, backed by regular inspections to spot chafe early and maintain peak holding power per the 7:1 scope rule.

These insights empower safer anchoring, but custom solutions from iRopes can elevate your setup with pre-spliced, ISO 9001-certified lines tailored for your boat. Whether upgrading hardware or preventing failures, personalised guidance ensures your connections endure any adventure.

Need Custom Rope Anchor Solutions? Get Expert Advice

If you're ready to explore bespoke ropes or splicing services to safeguard your marine setup, the inquiry form above connects you directly with iRopes specialists for tailored recommendations.