A 1‑inch four‑leg wire‑rope sling can be rated up to 34 t at a 60° angle, while 12‑strand UHMWPE winch rope offers high pull strength at a fraction of steel’s weight.

4‑minute read – What you’ll gain

- ✓ Cut rig‑up time with pre‑engineered bridle geometry and clear setup steps.

- ✓ Reduce shipment weight using high‑performance materials like 12‑strand UHMWPE.

- ✓ Manufacture under ISO 9001 with options to meet ASME B30.9 proof‑testing requirements.

- ✓ Use colour‑coding and branding to speed inspections and reduce identification errors.

You’ve probably been told that heavier steel rope is the only way to guarantee safety on high‑load lifts. iRopes’ 12‑strand UHMWPE solutions challenge that idea by delivering excellent tensile strength at far lower weight. In the sections below, we break down sling geometry, show angle‑adjusted capacity calculations, and explain how customised finishes—such as glow‑in‑the‑dark sheaths—streamline work on site.

four leg wire rope sling

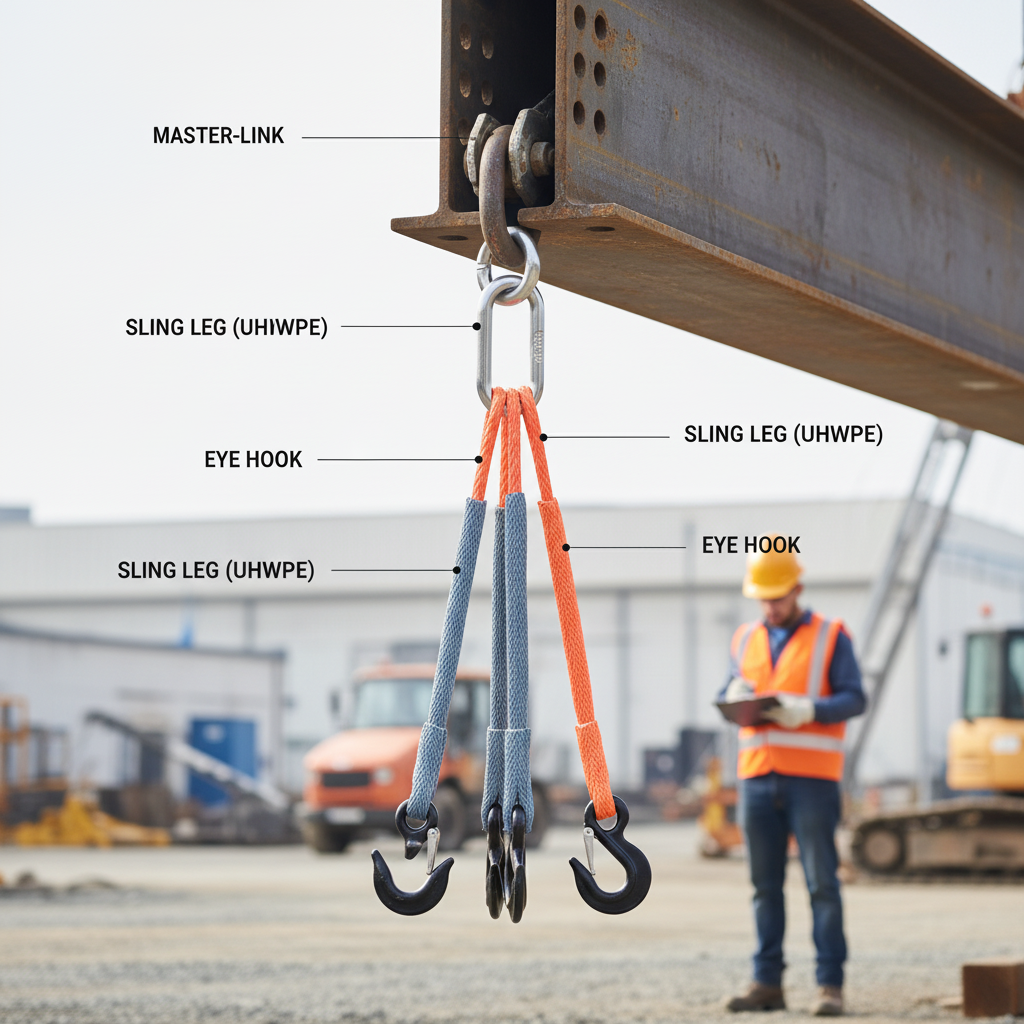

A four‑leg wire‑rope sling is a bridle‑type lifting device composed of four equal‑length wire‑rope legs joined at a master‑link, commonly used for symmetrical loads in construction, offshore rigs and recovery work. Its geometry distributes weight across multiple pick points, reducing point‑load stress on the load.

Definition, bridle geometry and typical industry use‑cases

The bridle forms a diamond‑shaped pattern where each leg meets the central master‑link. Adjusting the attachment points changes the leg angles, helping riggers maintain safer load‑angle ratios during lifts.

- Construction sites – lifting steel beams and prefabricated modules where precise load distribution is critical.

- Offshore platforms – handling heavy pipe spools and equipment in corrosive marine environments.

- Off‑road recovery – securing uneven loads on winches and recovery trucks.

Core construction details – wire‑rope core, strand count, and common end fittings

Inside each leg lies an independent wire‑rope core (IWRC) that can be specified in 6×19 or 6×36 construction. The strand count influences flexibility, fatigue resistance and tensile strength, while the outer coating—galvanised, bright‑steel or stainless—protects against corrosion.

- Strand count – typical options are 6×19 for flexibility and 6×36 for higher fatigue life.

- End fittings – latched eye hooks, thimbles, or heavy‑duty shackles are attached by swaging, socketing or mechanical connectors.

- Material grades – EIPS (Extra Improved Plowed Steel) offers an excellent balance of strength and wear resistance.

Comparison with 2‑leg and 3‑leg slings to illustrate load‑balance benefits

Compared with a two‑leg sling, a four‑leg configuration provides additional pick points and can improve stability on bulky or irregular loads. A three‑leg sling is lighter but may develop uneven tension on asymmetrical lifts. When rigged correctly, four legs help balance complex loads and reduce re‑rigging.

“Always verify the angle; a 30° lift can nearly halve the rated capacity compared with 60°.” — John Miller, Certified Rigger

Understanding the sling’s anatomy sets the foundation for the next step: applying load‑angle theory to determine the capacity needed for any lift.

four leg sling

Building on the anatomy of the bridle, the next logical step is to understand how the angle at which each leg meets the load influences the overall rating. Even a shift from 60° to 30° can dramatically reduce usable capacity, so angle awareness is a safety essential.

Load‑angle theory and its impact on capacity

When each leg forms a 30° angle with the vertical, the sine of the angle (0.5) increases leg tension and reduces the effective rating. At 45°, the sine is 0.707; at 60°, it is 0.866, which yields the highest effective capacity for a given rope diameter. In practice, many published capacities assume a 60° condition; for shallower angles, apply the ratio sin θ / sin 60° to the 60° figure.

For example, a ½‑inch four‑leg sling is typically rated around 8.8 t at 60°, 7.1 t at 45°, and 5.1 t at 30°. These values align with common capacity tables from leading suppliers.

Translating theory into a quick decision is straightforward. Start with the load weight, choose the lift angle, and then select the next‑larger standard rope diameter that meets the adjusted capacity.

Quick‑calc guide for diameter and length selection

- Identify the maximum load weight.

- Choose the intended lift angle (30°, 45°, or 60°).

- Apply the sine‑ratio to the published 60° capacity, then pick the nearest standard diameter that meets or exceeds the result.

Suppose a contractor must hoist a 4 t package at 45°. A ½‑inch sling rated 8.8 t at 60° adjusts to about 7.1 t at 45°, which is sufficient. At 30°, it adjusts to roughly 5.1 t—still acceptable, though many engineers step up to 5/8‑inch for added margin.

Answering a common query, “How do I calculate capacity for a four‑leg sling?” involves three steps: (1) start with the manufacturer’s 60° capacity, (2) multiply by sin (actual angle) / sin 60°, and (3) confirm the adjusted figure exceeds the load. This approach aligns with OSHA 1910.184 and ASME B30.9 guidance.

With a clear grasp of angle‑adjusted capacity and a simple sizing workflow, we can turn to winch lines used in off‑road recovery.

four wheeler winch rope

A four‑wheeler winch rope is a single line designed to wind on a recovery‑vehicle winch drum. Unlike a multi‑leg sling, it transmits pulling force directly from the winch to the stuck load, so tensile strength and abrasion resistance are critical.

Standard specifications fall between 3/8 inch (9.5 mm) and 1 inch (25.4 mm) in diameter, with lengths from 15 ft to 30 ft. Smaller diameters suit mid‑size 4×4 winches, while larger sizes pair with heavy‑duty units.

Key Specs

Diameter range 3/8–1 inch; length options 15–30 ft; material choices include steel or 12‑strand UHMWPE; compatible with most WARN, Superwinch and ARB winch models.

For material selection, steel rope offers excellent heat resistance and a familiar feel on the drum, but it adds significant weight. UHMWPE (ultra‑high‑molecular‑weight polyethylene) ropes—especially 12‑strand designs—deliver a high strength‑to‑weight ratio and very low stretch, which translates to smoother pulls and reduced winch‑motor strain. Protect UHMWPE from sharp edges and prolonged UV exposure with sleeves and covers.

Match the rope diameter to the winch’s rated pull – undersizing can cause premature wear, while oversizing adds unnecessary weight.

In plain terms, a four‑wheeler winch rope differs from a regular sling because it is a single line for pulling, not for distributing a static lift. A sling’s legs share weight across the load, whereas a winch rope transfers the entire force through one strand, so a safety margin of about 2× over the winch’s rated pull is common practice.

With definitions and material choices clarified, here’s how iRopes can customise winch ropes and slings to match your branding, colour and performance requirements.

customization & OEM advantages

Having clarified the rope’s definition, material choices, and how it stands apart from a conventional sling, the next step is to see how iRopes can tailor these products to match exact branding, colour, and performance requirements.

iRopes’ OEM/ODM program covers every stage of the product life‑cycle. Choose from steel, stainless, or 12‑strand UHMWPE, then specify colour, sleeve type, and branding placement. Throughout development, iRopes safeguards intellectual property with NDAs and traceable documentation, so your proprietary design remains protected end‑to‑end.

“The custom UHMWPE sling cut our lift‑cycle in half while meeting all ASME B30.9 inspections.”

This offshore case study shows the benefits of a fully custom solution. The client—an offshore wind‑farm contractor—needed a 12‑strand UHMWPE bridle with a glow‑in‑the‑dark sheath for night work. iRopes delivered ISO 9001‑manufactured gear that achieved a 30 % weight reduction versus steel, improved rig‑up speed by 25 %, and shipped on time across four ports. The sling met the required ASME B30.9 proof‑test.

- Define load parameters – weight, lift angle, and environmental factors.

- Select material & strand count – e.g., 12‑strand UHMWPE for high specific strength.

- Confirm branding & IP safeguards – logo placement, colour code, and confidentiality agreement.

When the checklist is complete, a single click on iRopes’ online portal generates a free custom quote, complete with CAD‑ready drawings and lead‑time estimates. Whether you need a four‑leg wire rope sling for heavy‑duty offshore lifts or a four‑wheeler winch rope for rugged recovery work, the same OEM framework ensures a seamless transition from concept to delivery.

The article has shown how a four leg wire rope sling’s bridle spreads weight across multiple points, how load‑angle calculations dictate the right diameter, and why 12‑strand UHMWPE rope delivers outstanding strength‑to‑weight performance for demanding offshore or recovery work.

Whether you need a four leg sling tuned to specific angles or a four wheeler winch rope built from steel or UHMWPE, iRopes’ ISO‑9001‑certified OEM/ODM service can tailor material, colour, branding and IP protection to your exact specs. Our engineers will help you select the optimal strand count, core type and accessories, ensuring safety and efficiency on every lift.

Request your personalised rope solution

For tailored advice and a free custom quote, simply complete the form above and our specialists will reach out to help you choose the perfect rope or sling for your application.