Have you ever wondered about the hidden heroes holding our world together? From the depths of the ocean to the heights of skyscrapers, three remarkable materials are quietly revolutionising industries and enhancing our daily lives. Welcome to the fascinating world of UHMWPE, nylon, and braided ropes.

In this eye-opening exploration, we'll unravel the impressive uses of these high-performance ropes across various sectors. Whether you're a seasoned professional or simply curious about the technology behind everyday objects, prepare to be amazed by the versatility and strength of these unassuming yet extraordinary materials.

Join us as we dive into the marine applications of UHMWPE, discover how nylon ropes are transforming outdoor adventures, and unveil the crucial role of braided ropes in industries you might never have imagined. By the end of this journey, you'll see the world around you through new eyes, recognising the incredible engineering that goes into the ropes that quite literally hold our modern lives together.

So, are you ready to discover the impressive uses of UHMWPE, nylon, and braided ropes? Let's embark on this enlightening adventure together and uncover the hidden strength beneath the surface of our everyday world.

Impressive UHMWPE Applications in Various Industries

Have you ever wondered about the secret material behind some of the toughest and most versatile products in various industries? Let me introduce you to UHMWPE, or Ultra-High Molecular Weight Polyethylene. This remarkable material has been revolutionising industries with its exceptional properties, and I've had the pleasure of witnessing its impact firsthand.

Key Properties of UHMWPE Driving Industrial Use

During my years working with manufacturing clients, I've seen UHMWPE's unique characteristics shine in countless applications. Here are the standout properties that make it a game-changer:

- Low friction: UHMWPE's slick surface reduces wear and tear on machinery, extending equipment life and reducing maintenance costs.

- Exceptional wear resistance: This material outlasts many traditional options, making it ideal for high-stress environments.

- Chemical resistance: UHMWPE stands up to harsh chemicals, making it perfect for use in corrosive environments.

These properties combine to create a material that's not just tough, but also incredibly versatile. It's no wonder that UHMWPE has found its way into so many different industries!

Diverse Applications of UHMWPE Across Sectors

Let's explore some of the fascinating ways UHMWPE is being used across various sectors:

UHMWPE in Manufacturing

Powering efficiency in conveyor systems, bearings, and gears

In manufacturing, UHMWPE is a workhorse. Its low friction and wear resistance make it ideal for conveyor systems, bearings, and gears. I once visited a factory that switched to UHMWPE conveyor parts and saw their maintenance downtime decrease by 30%!

The marine industry has also embraced UHMWPE. Its durability and resistance to saltwater make it perfect for dock fenders and pile guards. Imagine a material that can withstand constant battering from waves and boats without corroding - that's UHMWPE for you.

But perhaps the most impressive applications are in medical devices and ballistic protection. UHMWPE's biocompatibility makes it suitable for hip implants, while its strength-to-weight ratio makes it a top choice for body armour. It's humbling to think that the same material can both save lives in hospitals and protect them on the battlefield.

As we continue to push the boundaries of material science, who knows what other incredible applications we'll discover for UHMWPE? Its versatility and durability make it a material to watch in the coming years.

Have you encountered UHMWPE in your industry? I'd love to hear about your experiences with this remarkable material. Share your thoughts in the comments below!

Unveiling the Diverse Uses of Nylon Rope in Everyday Life

As I ran my fingers along the smooth, sturdy surface of a nylon rope, I couldn't help but marvel at its versatility. From my years working with various rope materials, I've come to appreciate nylon rope as a true workhorse in both professional and everyday settings. Let's dive into the myriad ways this remarkable material enhances our daily lives and supports crucial industries.

Essential Nylon Rope Applications for Home and Outdoors

Nylon rope has become an indispensable tool for homeowners and outdoor enthusiasts alike. Its combination of strength, durability, and flexibility makes it perfect for a wide range of applications. Here are some common uses you might encounter:

- Clotheslines and pet leashes: The UV-resistant properties of nylon rope make it ideal for outdoor use, ensuring your laundry stays put and your furry friends remain secure.

- Camping and hiking gear: From tying down tents to creating makeshift clotheslines at campsites, nylon rope is a camper's best friend.

- Garden support: Use it to train climbing plants or create sturdy trellises for your vegetable garden.

When selecting nylon rope for these tasks, consider the diameter and load capacity. A thinner rope might suffice for a clothesline, while a thicker one is better suited for securing heavy camping gear.

Industrial and Marine Uses of Nylon Rope

Beyond everyday applications, nylon rope plays a crucial role in various industries. Its ability to absorb shock loads and resist abrasion makes it invaluable in demanding environments. Here's where you'll find nylon rope hard at work:

- Marine environments: From mooring boats to fishing lines, nylon rope's resistance to saltwater degradation makes it a top choice for maritime use.

- Construction sites: Its high strength-to-weight ratio makes nylon rope perfect for lifting and securing heavy loads.

- Agricultural applications: Farmers rely on nylon rope for everything from bundling hay to securing livestock.

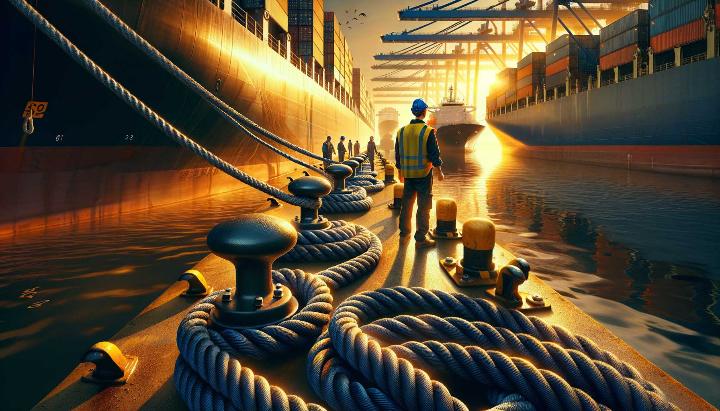

I once visited a busy harbour and was amazed to see how nylon ropes effortlessly held massive ships in place, despite the constant push and pull of the tides. It's a testament to the material's incredible strength and durability.

Whether you're a weekend warrior tackling home projects or a professional in need of reliable rigging solutions, nylon rope offers the versatility and strength to get the job done. Have you found any unique uses for nylon rope in your daily life or work? Share your experiences in the comments below – I'd love to hear how this versatile material has made a difference for you!

Versatile Braided Rope Uses Across Industries

As I run my fingers along the intricate weave of a braided rope, I'm reminded of its incredible versatility and strength. Having worked with various rope types throughout my career, I've come to appreciate the unique advantages that braided ropes offer across a wide range of industries. Let's dive into the fascinating world of braided ropes and explore their impressive applications.

Applications in Construction and Marine Sectors

In the construction industry, braided ropes are the unsung heroes of many job sites. I recall visiting a high-rise construction project where braided ropes were being used to lift and secure heavy loads. The site manager explained how the rope's superior strength-to-weight ratio and resistance to abrasion made it ideal for their demanding work environment.

Similarly, in the marine sector, braided ropes play a crucial role in various applications. During a recent trip to a busy harbour, I was struck by the sight of massive ships securely moored using braided ropes. The harbour master shared that these ropes are preferred for their excellent shock absorption properties and resistance to saltwater degradation.

Braided Rope Types and Their Unique Properties

The world of braided ropes is diverse, with each type offering unique properties suited for specific applications. Let's explore the five main types:

- Cotton braided rope: Soft to the touch and biodegradable, making it perfect for decorative uses and eco-friendly projects.

- Polyester braided rope: Known for its excellent UV resistance and low stretch, ideal for outdoor applications.

- Nylon braided rope: Offers high strength and excellent shock absorption, perfect for marine and industrial uses.

- Leather braided rope: Provides a unique aesthetic appeal and is often used in fashion and interior design.

- Hemp braided rope: A natural fibre rope with a rustic appeal, suitable for landscaping and organic gardening projects.

Each of these rope types has its own set of strengths, and choosing the right one can make all the difference in your project's success. Have you ever used a braided rope for a specific task? I'd love to hear about your experiences in the comments below!

As we continue to push the boundaries of material science and engineering, the applications for braided ropes are only expanding. From the construction site to the open sea, these versatile tools continue to prove their worth time and time again. Next time you come across a braided rope, take a moment to appreciate the ingenuity and craftsmanship that goes into creating these remarkable products.

Discover the Range of Uses for UHMWPE, Nylon, and Braided Ropes

Understanding the impressive UHMWPE uses, versatile nylon rope uses, and diverse braided rope uses can unlock a world of potential for various industries and applications. Whether it's leveraging the high-strength properties of UHMWPE in marine and industrial settings, benefiting from nylon rope's flexibility in everyday and professional tasks, or exploring the aesthetic and practical applications of braided ropes, these materials offer unmatched performance and durability. Fill out the inquiry form above to learn how iRopes can customise high-quality rope solutions to meet your specific needs and enhance your projects.