Have you ever wondered what makes a rope resilient enough to withstand the rigours of both land and sea, from off-road adventures to maritime escapades? Welcome to the world of iRopes, a leading rope manufacturing company that is redefining excellence in the industry. iRopes, based in China, is renowned for its precision manufacturing and high standards, making it a top choice for businesses worldwide. With a comprehensive range of rope products and services, iRopes leverages the latest technologies and skilled craftsmanship to deliver customised solutions tailored to meet the needs of diverse industries. Dive into this article to discover how iRopes is revolutionising the rope manufacturing process, ensuring quality, durability, and performance, all while maintaining competitive pricing and timely deliveries. Whether you’re in search of ropes for off-road, yachting, tree work, or industrial applications, iRopes has you covered with tailor-made solutions that exceed expectations.

iRopes: A Leading Rope Manufacturer

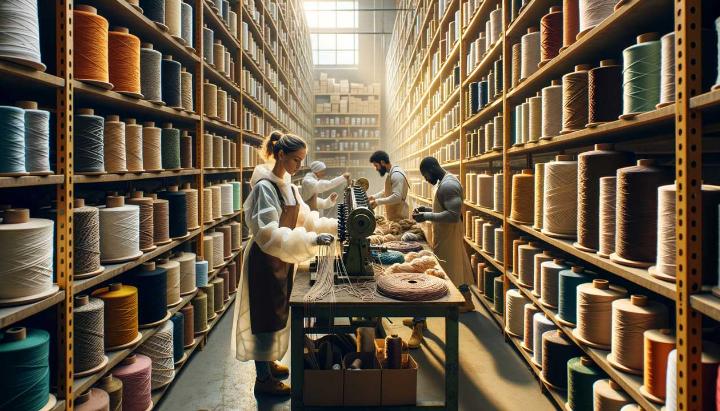

Nestled in the heart of China, iRopes stands as a shining beacon in the world of rope manufacturing. This trailblazing company has carved a niche for itself by crafting high-performance ropes that cater to a diverse range of industries, from marine and industrial to construction and outdoor recreation.

High-Performance Ropes for Various Industries

At iRopes, quality takes center stage. With an unwavering commitment to excellence, the skilled artisans meticulously craft ropes that boast unparalleled strength, durability, and specialized coatings. These high-performance ropes are tailored to meet the unique demands of each industry, ensuring optimal performance in even the most challenging environments.

From the rugged terrains of off-road adventures to the soaring heights of aerial endeavors, from the sturdy branches of arboreal work to the vast expanses of the open seas, iRopes' extensive product line caters to the needs of professionals and enthusiasts alike.

Commitment to Innovation and Research

Staying ahead of the curve is a core philosophy at iRopes. The company's unwavering dedication to continuous research and development has led to groundbreaking innovations in the field of rope manufacturing. By exploring new materials, cutting-edge technologies, and advanced manufacturing processes, iRopes consistently pushes the boundaries of what's possible.

Have you ever wondered how a rope can be engineered to withstand extreme temperatures or resist the corrosive effects of harsh chemicals? iRopes' team of experts leaves no stone unturned in their quest for developing tailor-made solutions that defy convention.

Innovation is the lifeblood of our company, and we're constantly pushing the boundaries to create ropes that surpass industry standards.

Moreover, iRopes takes great pride in its commitment to sustainability and environmental responsibility. By incorporating eco-friendly materials and adopting green manufacturing practices, the company ensures that its products leave a minimal carbon footprint, contributing to a greener tomorrow.

iRopes: A Comprehensive Range of Rope Products and Services

When it comes to rope solutions, iRopes stands as a leading provider that offers a truly comprehensive range of products and services. From high-performance ropes tailored for specific applications to expert crafting services that support global expansion, iRopes is dedicated to delivering customized solutions that exceed customer expectations.

Rope Accessories and Hardware for Customized Solutions

At the heart of iRopes' offerings lies an extensive collection of rope accessories and hardware components. These essential elements empower customers to create personalized solutions that align seamlessly with their unique requirements and industry demands. Whether you need specialized connectors, fittings, or rigging equipment, iRopes has it all.

Imagine being able to craft the perfect rope solution, tailored to your specific needs – that's the power iRopes puts in your hands. With their comprehensive range of accessories and hardware, customizing ropes for various applications across industries becomes an effortless reality.

Premium Rope Solutions for Every Industry

Beyond accessories, iRopes' core product offering revolves around premium rope solutions that cater to a wide range of industries. From synthetic fiber ropes to natural fiber variants, their extensive portfolio ensures that there's a reliable option for every application, no matter how demanding the environment or conditions.

Whether you're in the maritime, construction, arborist, energy, or any other industry, iRopes' premium ropes are engineered to deliver uncompromising durability, strength, and resilience. Their commitment to continuous innovation and product development ensures that their rope solutions evolve alongside the ever-changing needs of diverse industries, providing customers with cutting-edge performance and reliability.

- Abrasion resistance

- UV protection

- Rot resistance

From ropes designed to withstand abrasion and UV exposure to those that resist rot and other environmental factors, iRopes' premium solutions are engineered to excel in even the harshest conditions, ensuring your operations run smoothly and safely.

iRopes' Customized Rope Manufacturing Process

iRopes: A Comprehensive Range of Rope Products and Services

iRopes is a leading manufacturer of rope products and services, specializing in customized rope solutions for various industries. Our company offers a comprehensive range of rope products and services, including customized rope manufacturing, rope product testing and certification, and rope product installation and maintenance. We are dedicated to providing high-quality rope solutions tailored to meet the specific needs of our customers in the construction industry.

At iRopes, we recognize the importance of rope products in the construction industry, particularly in major projects and infrastructure development. Our experienced team of rope experts ensures that all rope products meet industry standards and comply with applicable regulations and codes. We work closely with our clients to understand their requirements and provide customized rope solutions that meet their specific needs.

The Role of Rope Products in the Construction Industry

iRopes: An Overview of Products and Services

iRopes is a leading provider of rope products and services for the construction industry. We offer a comprehensive range of rope products and services, including customized rope manufacturing, rope product testing and certification, and rope product installation and maintenance. Our team of experts is dedicated to providing high-quality rope solutions tailored to meet the specific needs of our customers in the construction industry.

iRopes' Services and Capabilities

iRopes: A Comprehensive Range of Rope Services

iRopes is a leading provider of rope products and services for the construction industry. We offer a comprehensive range of rope products and services, including customized rope manufacturing, rope product testing and certification, and rope product installation and maintenance. We are dedicated to providing high-quality rope solutions tailored to meet the specific needs of our customers in the construction industry.

Construction Industry Rope Products

iRopes: Providing Customized Rope Solutions

iRopes is a leading provider of rope products and services for the construction industry. We offer a comprehensive range of rope products and services, including customized rope manufacturing, rope product testing and certification, and rope product installation and maintenance. Our team of experts is dedicated to providing high-quality rope solutions tailored to meet the specific needs of our customers in the construction industry.

iRopes' Target Market and Key Strengths

As an industry-leading rope supplier, iRopes has developed an extensive global network for distributing their premium rope products. With strategically located facilities around the world, they can seamlessly fulfill orders and ensure reliable delivery to any location.

Mission

Provide high-quality and innovative rope products and solutions to meet the needs of our clients in various industries. Our goal is to offer exceptional value and a seamless experience.

Vision

Deliver industry-leading performance and a new standard of excellence in rope solutions and beyond.

We are committed to providing customized rope solutions tailored to meet your needs. Our team is dedicated to creating cutting-edge rope products while upholding the highest standards.

Our comprehensive range of rope products, combined with our innovative solutions, are designed to meet the most demanding requirements across various industries.

Our comprehensive range of rope products, combined with our innovative solutions, are designed to meet the most demanding requirements across various industries.

iRopes stands as a beacon in the world of rope manufacturing, offering high-quality ropes for various industries such as marine, construction, and outdoor recreation. As a leading rope manufacturing company, iRopes excels in creating customizable solutions tailored to the unique needs of wholesale customers. With precision manufacturing in state-of-the-art facilities and certified by ISO 9001, the company ensures each rope meets rigorous standards. The rope manufacturing process at iRopes takes into account factors like material, diameter, and length, providing specialized performance characteristics and compliance with certifications. Catering mainly to developed countries, iRopes’ strengths lie in innovation, flexibility, and timely delivery, making it an industry leader.

Interested in Custom Rope Solutions? Fill Out Our Form Below!

Our team at iRopes is ready to help you find the perfect rope solutions tailored to your needs. Fill in the inquiry form above to get started and discover how our expertise in rope manufacturing can benefit your business.