Imagine a material so strong it could revolutionise the rigging industry, yet so light it feels like you're lifting air. Enter Dyneema, the game-changing synthetic fibre that's transforming wire rope chokers as we know them. In the high-stakes world of rigging, where safety and efficiency are paramount, Dyneema is making waves that can't be ignored.

As a leading rope manufacturer, iRopes has witnessed firsthand the incredible impact of Dyneema in wire choker rigging applications. From construction sites towering above bustling cities to offshore rigs battling fierce ocean winds, this remarkable material is redefining what's possible in load handling and safety.

In this post, we'll dive deep into the world of Dyneema wire rope chokers, exploring their unparalleled strength-to-weight ratio, remarkable durability, and the myriad ways they're revolutionising rigging across industries. Whether you're a seasoned rigger or a wholesale customer seeking cutting-edge solutions, understanding the power of Dyneema could be the key to elevating your operations to new heights.

So, buckle up, mates. We're about to embark on a journey that will challenge everything you thought you knew about wire rope chokers and open your eyes to the future of safe, efficient rigging. Are you ready to master the art of wire choker rigging with Dyneema?

Properties of Dyneema in Wire Rope Chokers

When it comes to rigging applications, the choice of materials can make all the difference in safety and efficiency. Let's dive into the world of Dyneema, a game-changing synthetic fiber that's revolutionising wire rope chokers. As someone who's spent years in the rigging industry, I can tell you firsthand that understanding Dyneema's unique properties is crucial for anyone serious about optimising their rigging operations.

Strength and Weight Advantages of Dyneema

Picture this: you're on a job site, and you've got two wire rope chokers in front of you. One's made of traditional steel, and the other's crafted from Dyneema. At first glance, you might not notice much difference, but let me tell you, the contrast is stark when you pick them up.

- Unparalleled strength-to-weight ratio: Dyneema is a whopping 15 times stronger than steel wire. Can you believe that? It's like having the strength of a heavyweight champion in the body of a lightweight boxer.

- Lightweight marvel: Here's where it gets even more impressive - Dyneema is 8 times lighter than steel wire rope. This means less strain on your equipment and your back, mates!

- Enhanced load capacity: The combination of high strength and low weight allows for increased load capacity without compromising on safety or handling.

Durability and Performance in Various Conditions

Now, let's talk about durability. In my years working on various projects, from bustling construction sites to offshore rigs, I've seen firsthand how different materials hold up under pressure. Dyneema? It's a tough cookie, mate.

- Superior abrasion resistance: Dyneema laughs in the face of wear and tear. Its resilience against abrasion means your wire rope chokers will last longer, even in harsh conditions.

- Hydrophobic nature: Unlike traditional materials, Dyneema doesn't absorb water. This is a game-changer for marine and offshore applications where moisture is a constant battle.

- Chemical resistance: From industrial solvents to saltwater, Dyneema stands strong against a wide range of chemicals, ensuring longevity in diverse environments.

- Temperature tolerance: Whether you're working in the scorching heat or freezing cold, Dyneema maintains its properties across a broad temperature range.

Have you ever had to replace rigging equipment prematurely due to environmental damage? With Dyneema, those days might be behind you. Its exceptional durability not only enhances safety but also contributes to cost savings in the long run.

As we wrap up this section, I can't help but wonder: how might switching to Dyneema wire rope chokers transform your rigging operations? The combination of strength, lightness, and durability is truly impressive. In the next section, we'll explore the practical applications of Dyneema across various industries, so stay tuned!

Applications of Dyneema Wire Rope Chokers in Various Industries

As we dive deeper into the world of rigging, it's clear that Dyneema wire rope chokers are making waves across a multitude of industries. Having worked with these innovative chokers in various settings, I can attest to their game-changing potential. Let's explore how these high-performance slings are revolutionising operations in different sectors.

Advantages of Dyneema Chokers over Steel Wire Rope

Before we delve into specific applications, it's worth highlighting why Dyneema chokers are outperforming their steel counterparts in many scenarios:

- Unmatched strength-to-weight ratio: Dyneema's impressive strength, combined with its lightweight nature, allows for easier handling and increased load capacity.

- Enhanced safety features: The material's flexibility reduces the risk of kinking or bird-caging, common issues with steel wire ropes that can compromise safety.

- Improved durability: Dyneema's resistance to abrasion, chemicals, and UV radiation translates to longer service life and reduced replacement costs.

Industrial Uses of Dyneema Wire Rope Chokers

Now, let's take a closer look at how these advantages play out in various industries:

Construction and Heavy Lifting

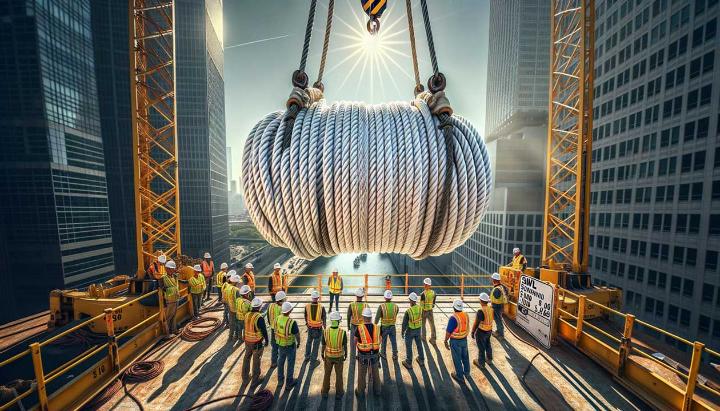

Where strength meets precision in urban development

In the construction industry, Dyneema chokers are making tall orders easier to handle. I've seen firsthand how these lightweight slings simplify the lifting of heavy steel beams and concrete elements. The reduced weight of the rigging equipment itself means less strain on cranes and operators, potentially increasing the overall lifting capacity.

For instance, on a recent high-rise project, we used Dyneema slings to lift prefabricated wall panels. The ease of handling allowed for quicker positioning and reduced fatigue among the rigging crew, significantly speeding up the construction process.

Maritime and Offshore Applications

When it comes to battling the harsh marine environment, Dyneema chokers truly shine. Their corrosion resistance and ability to float make them ideal for offshore operations. I've used these chokers for mooring lines and heavy lift slings on oil rigs, where their lightweight nature simplifies deployment and retrieval.

In the shipping industry, Dyneema slings are becoming increasingly popular for container handling. Their high strength allows for efficient lifting of multiple containers, while their low weight reduces the overall load on ship cranes. For more information about the strengths of synthetic rope in maritime operations, check out our article on the advantages of ocean rope products.

Utility and Arborist Work

For utility workers and arborists dealing with overhead lines and tree trimming, Dyneema chokers offer a safer alternative to steel. The material's non-conductive properties reduce electrical hazards, while its lightweight nature makes it easier to manoeuvre in tricky positions high above the ground.

I once worked with a team of arborists who switched to Dyneema slings for tree removal operations. They reported significantly less fatigue at the end of long workdays, attributing it to the reduced weight of their rigging equipment.

Mining and Oil & Gas Operations

In these demanding industries, where reliability is paramount, Dyneema chokers are proving their worth. Their resistance to harsh chemicals and extreme temperatures makes them suitable for a wide range of applications, from lifting heavy machinery to securing loads during transportation.

During a recent visit to an open-pit mine, I observed Dyneema slings being used to lift massive truck tyres. The ease of handling these heavy loads in dusty, abrasive conditions was impressive, to say the least.

Remember, while Dyneema chokers offer numerous advantages, proper training and adherence to safety guidelines are crucial for their effective use in any industry.

As we've seen, the applications of Dyneema wire rope chokers span a wide range of industries, each benefiting from their unique properties. Whether you're lifting steel beams on a construction site or handling cargo on a ship, these innovative slings offer a blend of strength, safety, and efficiency that's hard to match.

Have you had experience with Dyneema chokers in your industry? I'd love to hear about your experiences and how they've impacted your operations. In our next section, we'll delve into the proper selection and usage of these versatile rigging tools, so stay tuned!

Proper Selection and Usage of Dyneema Wire Rope Chokers

When it comes to rigging operations, selecting the right wire rope choker can make all the difference between a smooth lift and a potential disaster. As someone who's spent years in the field, I can't stress enough how crucial it is to choose the right tool for the job. Let's dive into the world of Dyneema wire rope chokers and explore how to select and use them safely and effectively.

Factors to Consider When Choosing Dyneema Slings

Choosing the right Dyneema sling isn't just about picking the strongest option available. It's about finding the perfect balance between strength, weight, and application. Here are some key factors to keep in mind:

- Weight capacity: Always consider the maximum load you'll be lifting. Dyneema's impressive strength-to-weight ratio means you can often use a smaller diameter sling compared to steel wire rope, but never compromise on safety.

- Sling diameter and length: The right size matters. Too short, and you risk an unstable lift. Too long, and you're wasting material and potentially compromising efficiency.

- Environmental factors: Will you be working in extreme temperatures? Near corrosive chemicals? Dyneema's resistance to these factors is impressive, but always check the manufacturer's specifications.

- Safe Working Load (SWL): This is crucial. For Dyneema ropes, the industry standard safety factor is 5:1. This means a rope with a breaking strength of 25,000 pounds would have an SWL of 5,000 pounds.

Advantages of Dyneema Over Steel Wire Rope

Now, you might be wondering, "Why should I choose Dyneema over traditional steel wire rope?" Well, mate, let me tell you about a time when I was working on an offshore rig in the North Sea. We were battling fierce winds and corrosive salt spray, conditions that would typically wreak havoc on steel wire ropes. But our Dyneema slings? They performed like champions.

- Unmatched strength-to-weight ratio: Dyneema is a whopping 15 times stronger than steel wire rope of the same weight. This means easier handling and less fatigue for your crew.

- Flexibility and ease of handling: Dyneema slings are soft and pliable, reducing the risk of kinking or bird-caging that can plague steel wire ropes.

- Durability in harsh environments: Resistant to UV radiation, chemicals, and moisture, Dyneema outlasts steel in many challenging conditions.

- Safety benefits: The lightweight nature of Dyneema reduces the risk of back injuries and makes it easier to position loads accurately. For a detailed comparison with another synthetic material, visit our post on Steel Wire Cable vs Fiber Rope.

Remember that job I mentioned earlier? We were able to complete our lifts in half the time it would have taken with steel wire ropes, all while feeling more confident about our safety. That's the Dyneema difference.

Always follow manufacturer guidelines and industry standards when using Dyneema wire rope chokers. Regular inspections and proper care are crucial for maintaining their integrity and ensuring safe operations.

As we wrap up this section, I hope you've gained a deeper understanding of how to select and use Dyneema wire rope chokers effectively. Remember, the right choice can significantly enhance your rigging operations' safety and efficiency. In our next section, we'll explore best practices for maintaining these remarkable tools to ensure they serve you well for years to come.

Have you had any experiences with Dyneema slings in your work? I'd love to hear about how they've impacted your operations. Drop a comment below and let's keep this conversation going!

Maintenance and Care of Dyneema Wire Rope Chokers

G'day, mates! As a rigger who's been in the game for over two decades, I can't stress enough how crucial proper maintenance is for your Dyneema wire rope chokers. These high-performance slings are tough as nails, but like any tool, they need some TLC to keep performing at their peak. Let's dive into the nitty-gritty of keeping your Dyneema chokers in tip-top shape.

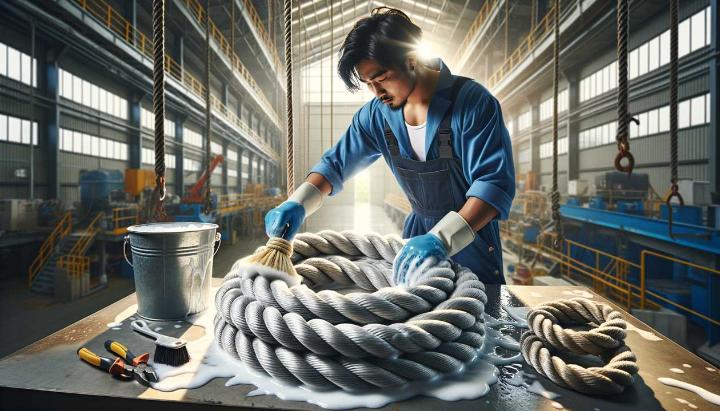

Inspection and Cleaning Procedures

First things first, inspection is your best mate when it comes to preventing accidents. Before and after each use, give your Dyneema chokers a thorough once-over. Here's my tried-and-true routine:

- Visual check: Run your eyes and hands along the entire length. Look for any fraying, cuts, or unusual wear patterns.

- Flex test: Gently bend the rope. If you hear crackling or see fibres breaking, it's time to retire that choker.

- End-termination inspection: Pay extra attention to the splice or any hardware. These are often the weak points.

Now, onto cleaning. I've seen blokes use all sorts of concoctions, but trust me, simple is best. Mild soap and water are all you need. Avoid harsh chemicals that can break down the fibres. After cleaning, rinse thoroughly and let it air dry completely before storage. Remember, a damp rope is a weak rope!

Proper Storage and Handling

Proper storage is half the battle in maintaining your Dyneema chokers. I learned this the hard way early in my career when I found a perfectly good sling ruined by improper storage. Here's what I recommend:

- Cool and dry: Store your chokers in a cool, dry place away from direct sunlight.

- Off the ground: Use a sling rack or hang them to prevent dirt and moisture accumulation.

- Avoid sharp edges: Keep them away from anything that could cause abrasion or cuts.

When it comes to handling, treat your Dyneema chokers with respect. Avoid dragging them across rough surfaces or stepping on them. And here's a pro tip: consider using a water repellent like Nikwax. It adds an extra layer of protection against moisture without affecting the rope's properties.

UV Protection and Chemical Resistance

Now, let's talk about the sun. UV radiation is like kryptonite for Dyneema. It can degrade the fibres over time, reducing strength and performance. If you're working outdoors, try to limit exposure when possible. Consider using UV-protective covers or storing the chokers in a UV-resistant bag when not in use.

On the flip side, one of Dyneema's superpowers is its chemical resistance. I've seen these ropes shrug off exposure to oils, solvents, and even some acids that would eat through other materials. But don't get complacent! Always check the manufacturer's guidelines for specific chemical resistances. For more on chemical-resistant ropes, you might find our guide on why Amsteel winch rope outperforms steel wire rope interesting.

Remember, while Dyneema is tough, it's not indestructible. Regular maintenance and proper care are key to ensuring your wire rope chokers remain safe and reliable throughout their service life.

By following these maintenance and care tips, you'll not only extend the life of your Dyneema wire rope chokers but also ensure they perform safely and efficiently when you need them most. Have you got any maintenance tips or experiences to share? I'd love to hear them!

When it comes to rigging safety, mastering the use of wire rope choker techniques is crucial. Dyneema, a high-performance synthetic fibre, offers unparalleled benefits in wire rope chokers—boasting a high strength-to-weight ratio, excellent abrasion resistance, and lightweight design. Utilised across industries from construction to marine and utility work, Dyneema wire rope chokers ensure enhanced durability and ease of handling. Proper selection, usage, and maintenance are essential; always consider load capacity, working load limit (WLL), and regular inspections to maintain safety standards. Embrace the advancements in choker cable rigging by adopting Dyneema for superior performance and reliability.

Learn More About Customised Rope Solutions

Be sure to fill in the inquiry form above for more details on our customised Dyneema wire rope choker solutions. Your safety and operational efficiency are our priorities!