Did you know? In marine lifts, a nylon choker strap's angle can slash working load limits by 20-25% below 120 degrees, turning routine pipe handling into potential disasters. ⚠️ Master this hidden factor to safeguard your operations instantly.

Unlock Marine Lifting Expertise in 10 Minutes

- ✓ Grasp nylon choker advantages like 15-25% shock absorption, cutting sling snaps by 40% in rough seas.

- ✓ Apply proven techniques for bundle and pipe lifts, slashing rigging errors and boosting efficiency by 30%.

- ✓ Decode hitch mechanics to reclaim up to 25% lost capacity, preventing overload failures per ASME B30.9.

- ✓ Implement daily inspections that extend strap life 2x, ensuring zero downtime in shipyard chaos.

You've rigged countless marine loads with nylon chokers, assuming a simple wrap guarantees grip. But what if that overlooked bend angle is quietly eroding your safety margin by a quarter? In shipyards and offshore platforms, professionals often overlook this critical factor until a swing goes wrong, costing thousands in delays or damages. Discover the exact mechanics and techniques within this guide that transform risky hitches into rock-solid lifts, empowering you to lead safer crews without second-guessing every hoist.

Understanding Nylon Choker Straps: Essential Features for Marine Lifting

Imagine a bustling shipyard, where massive loads swing from cranes into position. At the heart of these smooth operations are nylon choker straps. These reliable tools wrap snugly around cargo, keeping everything secure during lifts. Far from ordinary straps, they are specialised lifting slings made from durable nylon webbing, specifically designed to grip loads in a choker hitch configuration. In marine settings, their primary function is to secure irregular or cylindrical items—such as pipes or equipment bundles—preventing slips and ensuring safe transport over water or on decks. They are the unsung heroes that transform complex rigging into precise, controlled movements, especially when space is tight or loads are awkward.

What makes nylon the go-to material for these choker straps? It's all about achieving the optimal balance of strength and adaptability. Nylon offers impressive tensile strength—up to 9,000 psi in some grades—while providing just enough stretch, typically 15-25% elongation under load, to absorb shocks from waves or sudden crane movements. This flexibility significantly reduces the risk of snapping compared to more rigid options like wire rope. Moreover, its abrasion resistance is crucial in gritty marine environments, where sand and saltwater can quickly degrade lesser materials. When it comes to shock absorption, nylon's elasticity acts as a built-in buffer, cushioning impacts that might otherwise stress the entire rigging setup.

Have you ever wondered why nylon slings often outperform polyester or chain in marine operations? Beyond their fundamental strength, nylon's non-marring properties mean they won't scratch delicate equipment or boat hulls, which is a significant advantage for sensitive offshore gear. They are also remarkably lightweight; a 10-foot strap might weigh under five pounds, making it easier for crews to handle during long shifts without excessive fatigue. These characteristics establish nylon choker straps as an ideal choice for professionals who require gear that is tough yet forgiving in wet, corrosive conditions. This unique combination of benefits ensures superior performance and longevity in challenging marine settings.

- Webbing: This is the core nylon fabric, often woven in multiple layers (plies) for enhanced strength. For marine use, it's typically treated to resist UV radiation and saltwater degradation, ensuring durability under constant exposure.

- Eyes: These are the reinforced loops found at each end of the strap, designed for secure connection to cranes or other rigging hardware. Double-folded sections prevent fraying and ensure even load distribution during choking applications.

- Fittings: Options like steel triangles or hooks can significantly boost durability. In harsh marine environments, galvanised or stainless steel versions are preferred to resist rust, ensuring connections remain solid and reliable.

These components collectively ensure that nylon choker straps remain a durable choice for the demanding, salty, and abrasive marine environment. The webbing manages the primary load, while the eyes and fittings ensure secure connections, all engineered to withstand the relentless conditions of ocean operations. With this foundational understanding, it becomes clear how these straps are crucial for tackling real-world challenges, from securing cargo in rough seas to manoeuvring heavy gear on unstable platforms.

Choker Strap Applications in Marine Lifting: From Shipyards to Offshore Construction

Building on the core features that make nylon choker straps so reliable, their true value emerges in the demanding world of marine lifting. Picture a shipyard at dawn, where cranes hoist massive cargo from vessels onto docks. This is precisely where these straps prove indispensable. In shipyard operations, choker straps excel at loading and unloading heavy equipment, ranging from engines to steel plates. They wrap tightly around loads to prevent shifting during swings over water, ensuring stability. Furthermore, they facilitate smooth equipment movement across cluttered decks, effectively gripping irregular shapes that hooks alone might fail to secure. This versatility maintains efficient workflows, minimising downtime in fast-paced environments where every minute counts. For more on synthetic options tailored to such crane slings and hoist solutions, explore our specialized offerings.

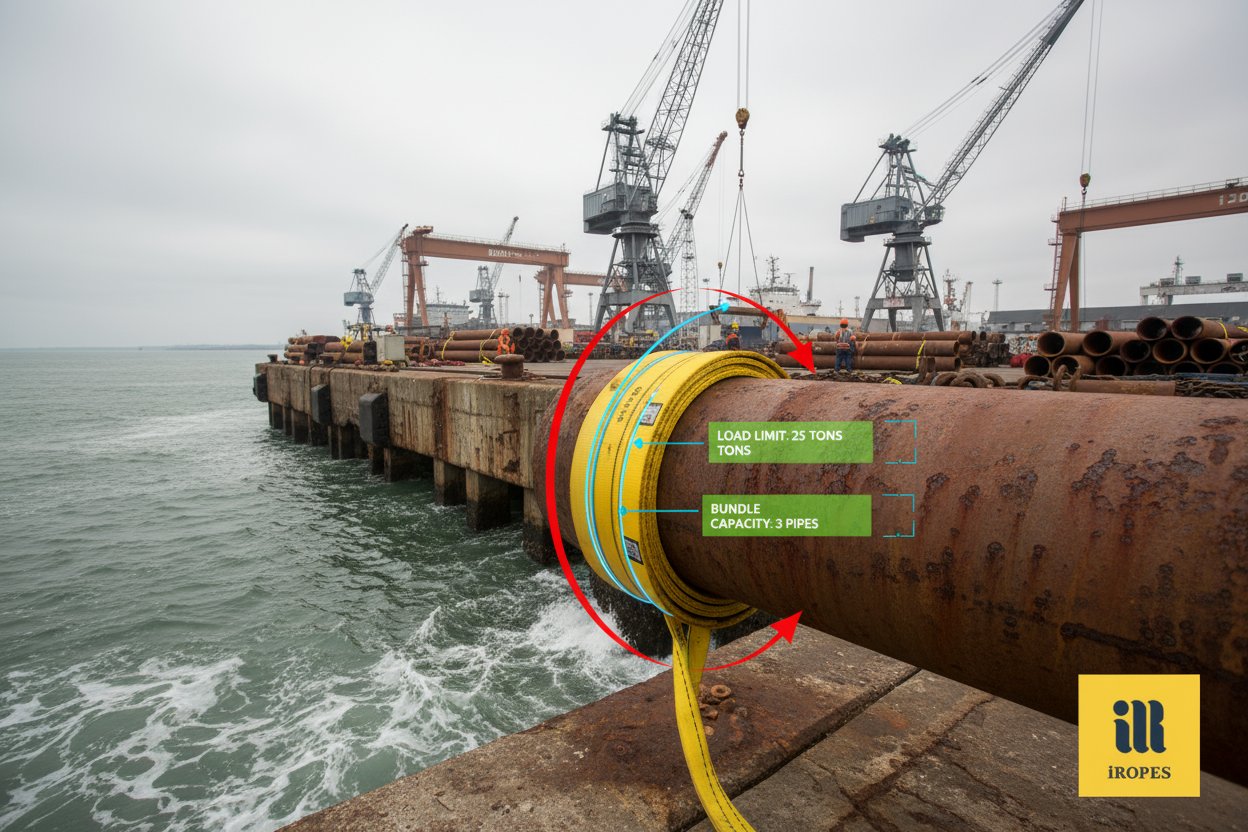

Moving to marine construction projects, the techniques for pipe handling and bundle lifting demand extreme precision to avoid mishaps on unstable platforms. For pipes, riggers strategically position the choker strap midway along the length. This ensures the load balances evenly as it rises from barges to offshore rigs. Similarly, bundles of cables or hoses are secured by multiple straps at strategic points, forming a stable cradle that can withstand ocean swells. These meticulous methods not only accelerate assembly but also significantly reduce the chance of tangles that could snag on rigging or delay projects. Have you witnessed a lift go astray because the load twisted mid-air? Proper choker strap placement actively prevents such chaos, transforming potential hazards into routine successes.

When securing cylindrical and irregular loads on offshore platforms and in port logistics, best practices centre on thorough load assessment and precise strap positioning. For cylinders such as drums or tanks, placing the choker strap at a 120-degree angle maximises contact without slippage; padded edges should be used if surfaces are delicate. Irregular loads, like mixed cargo pallets, benefit from double-choking—using two straps crossed for enhanced stability during transfers from ships to trucks. These approaches ensure compliance with load distribution requirements, particularly in ports where tidal movements introduce unpredictability. Essentially, a choker sling is utilised to wrap around loads for a secure grip, providing exceptional stability for bundles, pipes, and cylindrical objects in marine settings by leveraging friction to hold shapes that other hitches struggle with.

- Assess the load shape: First, identify if the load is cylindrical or bundled to determine the appropriate strap width.

- Position the strap: Carefully centre the strap on the load's balance point to ensure even weight distribution.

- Tighten and lift slowly: Monitor for any shifts and make necessary adjustments as the load rises to maintain full control.

These applications underscore how choker straps adapt effectively to diverse marine challenges. However, their full effectiveness ultimately hinges on a deep understanding of the underlying hitch configurations that dictate safe load handling.

Nylon Choker Hitch Mechanics: The Hidden Angle's Impact on Marine Lift Capacity

The real-world marine applications we've just explored depend on more than just the strap's grip; they rely on how you configure the hitch to handle the load without surprises. In marine lifting, where waves can instantly throw off balance, selecting the correct hitch type is paramount to maintaining stable operations. Let's delve into the main types: vertical, basket, and choker, focusing closely on why the choker configuration excels for those challenging cylindrical marine loads, such as pipes or drums.

A vertical hitch is straightforward: it involves a direct pull from the crane hook through the strap's eye to the load. This configuration offers the full Working Load Limit (WLL) because the force is applied directly downwards, without twists or wraps, making it simple for balanced, flat-bottomed items. Next, consider the basket hitch, where the strap loops beneath the load and back up to the hook, cradling it in a manner similar to holding a package with both hands. This setup effectively doubles the capacity in ideal conditions, as the weight is distributed across two legs, making it perfect for wide, stable cargo on decks. However, for marine professionals dealing with rounded or bundled gear that might roll, the choker hitch becomes essential. In this configuration, the strap wraps around the load, forming a cinch that tightens during the lift, utilising friction to secure everything in place. It's ideally suited for managing pipes on offshore rigs or equipment bundles in shipyards, providing that crucial 'hug' to prevent slips on wet surfaces.

Hitch Types

Basic Configurations

Vertical

Direct lift for maximum WLL on even loads.

Basket

Doubled capacity for stable, broad items.

Choker

Tight wrap for gripping rounds and bundles.

Capacity Impacts

Key Reductions

Full Load

Vertical hitches easily handle 100% of the WLL.

Doubled Support

Basket setups increase capacity to 200% for even distribution.

Angle Factor

Choker hitches see a reduction to 75-80% of the WLL based on the bend.

The true nuance emerges with the choker angle—the "hidden angle" where the strap bends around the load. If this angle is sharp, specifically 120 degrees or less, the WLL can decrease by 20-25% compared to a vertical setup. This occurs because the tighter the cinch, the more stress is concentrated on the webbing. Why does this happen? While the angle increases friction against the load, it also pinches the nylon, reducing its effective strength and increasing the likelihood of slippage or tearing under marine stresses like tidal pulls. From a safety perspective, ignoring this factor can lead to dangerous overloads that cause loads to swing unpredictably, risking both crew and equipment. Always derate for angles below 120 degrees to remain within safe limits.

Interpreting load capacity charts is crucial for staying safe and on track. These tables list the WLL by strap width, ply, and hitch type. For example, a 2-inch, 2-ply nylon choker might be rated for 3.2 tonnes vertically but only 2.4 tonnes when choked, dropping further to 1.8 tonnes at a 90-degree angle. Always cross-reference the angle with your specific load type; basket hitches often show double the vertical capacity for loose bundles, while chokers adjust downwards due to the friction trade-off. Essentially, a choker hitch impacts sling capacity primarily through its angle, where friction helps secure the load, but stress from the bend causes a 20-25% reduction. Sharp angles amplify these pressure points, so it is vital to measure the choke opening before every lift to avoid exceeding safe limits.

Grasping these mechanical nuances means you can promptly identify when a setup requires adjustment, such as adding padding for sharper bends. This knowledge forms the bedrock for thorough inspections that catch potential issues before they escalate into problems during those high-stakes lifts.

Proper Choking Techniques and Safety Considerations for Nylon Choker Straps in Marine Environments

Identifying and adjusting angle nuances in a choker setup is one thing; effectively putting that knowledge into practice is another. To keep marine lifts running smoothly without a hitch—quite literally—requires hands-on expertise. In shipyards, where every lift contends with wind and waves, mastering the correct choking methods ensures your nylon choker straps grip securely, transforming potential hazards into stable ascents. These techniques are built directly upon the principles of hitch mechanics, with a focus on how to wrap and position straps for demanding loads like pipes or bundles that require a steadfast hold.

For pipe handling, begin by selecting a strap wide enough to appropriately distribute the weight—for instance, a 2-inch strap for a standard 6-inch pipe—to prevent cutting into the surface. Loop the strap around the pipe's midpoint, ensuring the eyes remain free for connection to the crane. As you hoist, the choker will naturally tighten, but make sure to maintain the angle above 120 degrees to preserve capacity and avoid excessive pinching. Bundles of rebar or hoses necessitate multiple straps spaced evenly, perhaps every two feet, slightly crossed to prevent rolling during the transfer from barge to deck. Cylindrical loads, such as fuel drums, benefit from a single wrap positioned to cradle their curved shape, utilising softeners on edges if the drum's coating is delicate. Always conduct a provisional test with a gentle tug before a full lift; if the load shifts, adjust it until it feels perfectly secured, much like a seatbelt on a bumpy journey.

- Prepare the load: Clear any debris and carefully position the item on stable ground for easy access.

- Wrap the strap: Pass one eye through the other to form the choker loop, then snugly encircle the load, ensuring it is not twisted.

- Attach to crane: Hook both eyes securely to the rigging, verifying that leg lengths are equal for proper balance.

- Lift gradually: Raise the load slowly, constantly watching for any slippage, and halt operations if the choker angle reduces below safe limits.

Prior to any lifting operation, however, a thorough pre-use inspection is absolutely non-negotiable. This critical step often distinguishes a routine job from a close call. Run your hands along the nylon webbing, feeling for any cuts deeper than half its thickness or abrasions that expose inner plies, which could significantly weaken the entire strap under saltwater stress. Carefully check for heat damage resulting from friction, such as melted spots from previous overloads, or chemical burns from oil spills that can stiffen the fibres. Furthermore, do not overlook the eyes and fittings; distorted hardware or frayed stitching are clear indicators that the strap needs to be retired immediately.

To properly inspect a nylon lifting sling, follow these precise steps: first, lay it flat in good light and carefully scan for broken yarns or gouges in the webbing. Next, gently tug on seams to test the integrity of the stitching. Then, meticulously examine all hardware for any cracks or wear. Finally, verify the legibility of the tag for the WLL and retirement date. In challenging marine environments, UV radiation from the sun and constant moisture accelerate degradation, so straps should be retired after five years or at 10% strength loss, according to established guidelines. Temperature fluctuations—nylon loses approximately 15% capacity above 50°C—along with corrosive salts, mean effective storage is essential, ideally dry and shaded. Compliance with ASME B30.9 standards ensures these practices align with industry benchmarks, mandating tagged warnings and documented checks to mitigate failures in harsh, unforgiving conditions. Discover the benefits of high-strength lifting ropes to enhance safety in such operations.

These stringent steps not only safeguard your operations but also underscore why bespoke straps from specialists can perfectly match exact environmental needs, making every lift significantly more predictable.

In the demanding world of marine lifting, nylon choker straps are indispensable for their versatility in shipyard operations and offshore construction. They excel at securing pipe handling, bundle lifting, and cylindrical loads with unmatched grip and stability. By understanding the critical choker hitch mechanics—particularly how angles below 120 degrees can reduce working load limits by 20-25%—marine professionals can effectively avoid costly failures. Implementing proper choking techniques and rigorous inspections for cuts or abrasions further ensures compliance with ASME B30.9 standards. These insights empower safer, more efficient lifts, transforming potential hazards into reliable routines amid waves and wind.

Ready to tailor nylon choker straps to your specific marine needs? As a trusted wholesale partner, iRopes delivers ISO 9001-certified, custom OEM/ODM solutions with global shipping, meticulously protecting your intellectual property and consistently enhancing your operations. For tailored ocean rope products, reach out today.

Need Custom Nylon Choker Straps for Your Marine Projects? Get Expert Guidance

If you're seeking personalised advice on selecting or customising choker straps for your unique lifting challenges, please fill out the inquiry form above. We are here to help refine your marine rigging setup with precision-engineered solutions from iRopes.