AmSteel‑Blue delivers up to 19,600 lb breaking strength in a 3/8″ line while weighing 85% less than comparable steel cable. The 1/8″ version still pulls 2,500 lb for a fraction of the weight, giving you steel‑grade power with feather‑light handling.

Quick‑scan Benefits (≈1 min read)

- ✓ 85% weight reduction vs steel specimens — cuts handling fatigue and shipping costs.

- ✓ Breaking strength up to 19,600 lb (3/8″) and 2,500 lb (1/8″) — covers light‑rigging to heavy‑duty winching.

- ✓ Near‑zero stretch (less than 0.5% at 10% load) — ensures precise control for winches and moorings.

- ✓ Floats on water and resists abrasion, boosting safety and lifespan in marine and off‑road use.

Most crews still lug bulky steel cables, wrongly assuming only they can handle the heaviest loads. They don't realise that AmSteel‑Blue provides the same or greater breaking strength while being up to 85% lighter, floating in water and stretching less than half a percent. This revolutionary rope transforms handling, bolsters safety, and streamlines logistics. Read on to discover how you can swap steel for a high-performance synthetic line that boosts your operational efficiency without adding extra weight.

AmSteel‑Blue – High‑Performance Dyneema Rope Overview

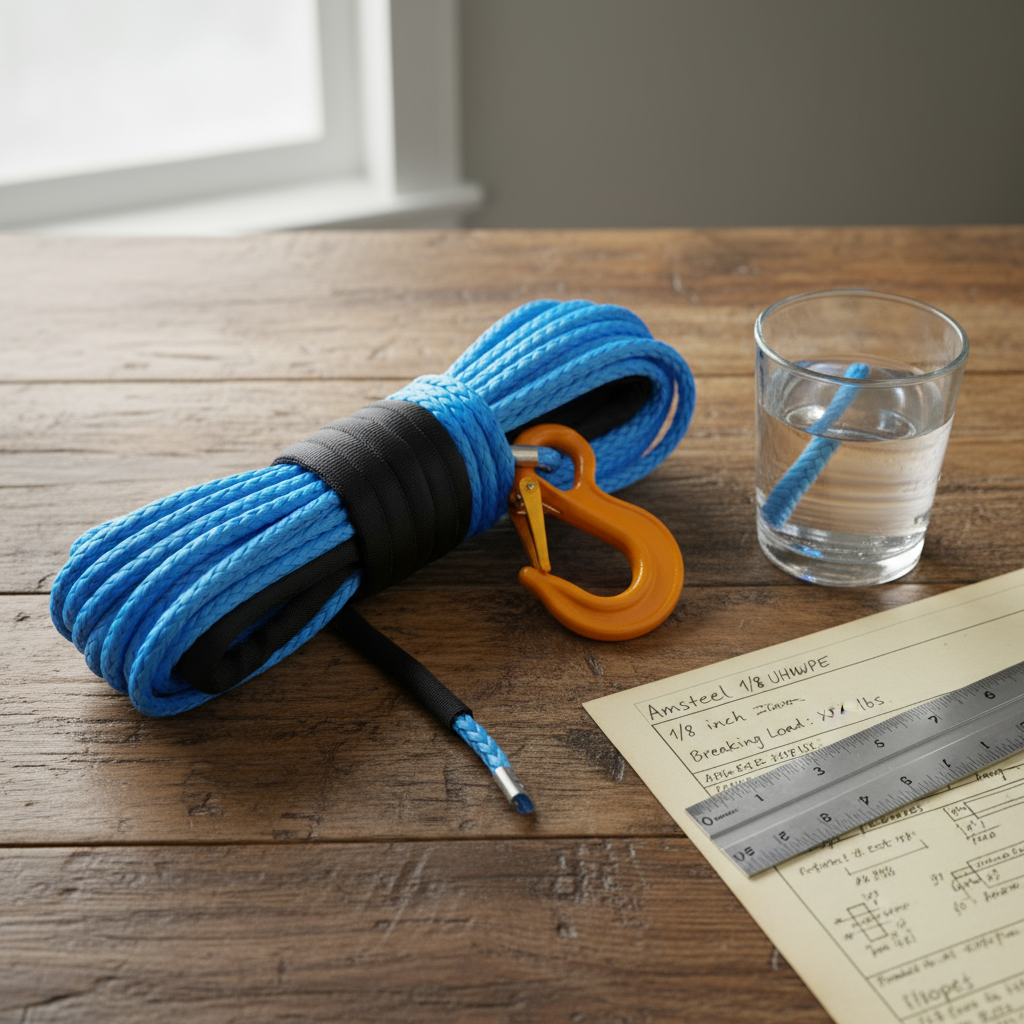

When you first run your fingers along a length of AmSteel‑Blue, its sleek, sky‑blue hue and subtle smoothness immediately stand out. This isn't merely an aesthetic choice. The rope is meticulously constructed from 100% UHMWPE (Dyneema) fibres, further enhanced with a Samthane coating. This coating acts as a robust protective skin, providing exceptional abrasion resistance and guarding the fibre core against moisture, ensuring it remains ready for the toughest tasks.

What makes this rope feel so remarkably light yet so incredibly strong? The secret lies in its advanced 12‑strand single‑braid construction. Each strand is designed to be torque‑free, which means the rope will not twist under load, making splicing effortless and free from unwanted rotation. Composed of high‑modulus polyethylene fibres, AmSteel‑Blue exhibits minimal stretch—less than half a percent even at ten percent of its breaking load. This attribute translates directly to precise control, which is critical for winching and rigging applications.

- Material composition – 100% Dyneema (UHMWPE) fibres with a Samthane coating for enhanced durability.

- Construction details – 12‑strand single braid, torque‑free design, and easy‑to‑splice architecture.

- Core benefits – exceptional strength‑to‑weight ratio, minimal stretch, natural flotation, and a snap‑back‑free safety profile.

If you've ever wondered about the true strength of AmSteel‑Blue, imagine a rope capable of handling the load of a small car winch, yet it still floats if inadvertently dropped into water. This unique combination of strength and buoyancy is why marine crews, off‑road enthusiasts, and arborists consistently rely on this rope for their most critical tasks. Previously, I assisted a client in replacing a steel cable on a recovery winch with AmSteel‑Blue; the new line was half the weight, floated reliably during testing, and required no additional hardware for splicing. This transformation greatly improved their operations.

“The moment I felt the rope lift a 2,000 lb load without a hint of stretch, I knew AmSteel‑Blue had redefined what a synthetic line could do.” – Senior recovery technician

Understanding these fundamental characteristics sets the stage for exploring the specific capabilities of the 1/8‑inch version, where its precise balance of lightness and strength opens up a whole new range of specialised applications.

1/8 AmSteel‑Blue – Precise Strength for Specialised Tasks

Building on the overview of AmSteel‑Blue's construction, the 1/8‑inch size delivers a remarkable balance of feather‑light weight and substantial pulling power. It particularly excels in niche applications where bulk is a significant liability. If you need a line that maintains its integrity under a modest load yet remains exceptionally easy to handle, this diameter is the ideal choice.

Looking at its specifications, the 1/8-inch AmSteel-Blue boasts an average breaking strength of approximately 2,500 lb (≈1,134 kg). This figure translates to a robust safety factor of about 5 when operating within a typical 500 lb working load, providing significant confidence whether you're battling a windy day on the water or securing a campsite tarp. The rope’s inherently low‑stretch characteristic ensures the line holds its length almost rigidly, meaning your knots and splices remain secure and true under load.

- Camping guylines – light enough to pack, yet strong enough to hold a tent securely in a gale.

- Small‑craft control lines – provides reliable performance for dinghy steering or inflatable board rigging.

- Arborist lashing and kite‑boarding – offers precise tension without introducing unnecessary bulk.

When addressing the common query, “How strong is AmSteel‑Blue rope?”, the 1/8‑inch size's 2,500 lb rating places it squarely in the same performance class as a thin steel cable. Crucially, it achieves this while weighing roughly 80 percent less. The practical result is a line you can effortlessly lift, coil, and store, completely eliminating the muscle strain associated with its heavier metal equivalents.

Strength Fact

A 1/8‑inch AmSteel‑Blue line breaks at about 2,500 lb, delivering the pulling power often associated with a steel cable, while remaining buoyant and easy to splice. This combination makes it ideal for lightweight rigging where every gram counts.

Because this rope floats, you'll never have to pursue a sinking line after an unexpected mishap at sea. Furthermore, its Samthane‑coated fibres effortlessly shrug off abrasion from elements like sand or tree bark. Whether you're setting up a portable shelter, meticulously trimming a sail, or rigorously securing a climbing anchor, the 1/8‑inch option provides the confidence of steel-like strength with the superior handling ease of a synthetic line.

→ Now, we'll examine how the larger 3/8‑inch version scales up to meet heavy‑load demands while retaining the same core advantages and advanced capabilities.

3/8 AmSteel‑Blue Rope – Heavy‑Duty Power for Demanding Operations

Having explored the nimble strength of the 1/8‑inch version, we now turn to the 3/8‑inch AmSteel‑Blue rope, which is designed for situations where raw power is absolutely non‑negotiable. Despite its substantial capabilities, its 12‑strand, torque‑free braid still feels surprisingly light. Yet, it can withstand forces that would effortlessly compromise a conventional steel cable.

This heavy‑duty rope boasts a breaking strength ranging impressively from 17,600 lb to 19,600 lb (≈7,980–8,890 kg), effectively placing it in the same performance class as many industrial steel wires. Moreover, because its synthetic core floats, any line dropped into water can be promptly retrieved, eliminating the frantic search typically associated with steel ropes. When considering the question, “Is AmSteel‑Blue lighter than steel rope?”, the answer is a resounding yes – it weighs approximately 80‑85% less. This significant weight reduction directly translates to easier on‑site handling and considerably lower shipping costs.

Performance

Why the 3/8 excels

Strength

Average breaking strength between 17,600 lb and 19,600 lb (≈7,980–8,890 kg) for industrial‑grade tasks.

Weight

Up to 85% lighter than comparable steel wire, drastically reducing handling fatigue and transport costs.

Flotation

Synthetic core ensures the rope floats, significantly improving safety and retrieval in marine recovery operations.

Applications

Where the rope shines

Winch lines

Handles the high loads of off‑road recovery winches, eradicating the dangerous snap‑back risk inherent with steel cables.

Mooring

Serves as primary mooring lines for yachts and workboats, providing superior strength and swift deployment capabilities.

Heavy rigging

Ideally suited for construction lifts, severe‑weather towing, and any industrial rigging scenario where unwavering reliability is mission-critical.

Because the rope’s low‑stretch characteristic maintains the line virtually rigid under load, operators experience highly precise control during winching or towing operations. This eliminates the unpredictable elongation that can throw off calculations with other ropes. Envision a recovery vehicle on a slick desert trail; the 3/8‑inch AmSteel‑Blue line delivers the necessary pulling power to free a stuck axle, while remaining light enough for a single crew member to manage safely and efficiently.

Because AmSteel‑Blue’s core is both ultra‑light and exceptionally strong, it adapts seamlessly across a diverse spectrum of sectors. This performance is typical of UHMWPE ropes, which outperform traditional wire ropes in weight and durability. Off‑road recovery teams highly value its rapid‑handleability for winch lines, while yachting crews depend on this very same material for primary mooring, where its flotation capability acts as a crucial safety lifeline.

For a detailed comparison of synthetic fiber ropes versus traditional steel cables, see our steel cable vs. fiber rope analysis. This insight highlights why many professionals now prefer fiber solutions for both safety and cost efficiency.

Tailored Solutions & Industry Applications

After witnessing the sheer pulling power of the 3/8‑inch AmSteel‑Blue rope, a natural question arises: how can this formidable capability be precisely tailored to the specific demands of your operations? At iRopes, we excel at transforming the generic strength of this exceptional line into a personalised tool that perfectly aligns with your brand, logistical needs, and performance targets.

Our comprehensive OEM/ODM service begins with a straightforward brief from you. Simply outline your requirements: the precise length and diameter (whether you need a 1/8‑inch AmSteel‑Blue line for lightweight rigging or a 3/8‑inch AmSteel‑Blue rope for heavy‑duty winching), your preferred colour palette, and any necessary accessories such as loops, thimbles, or reinforced terminations. From this initial input, our dedicated design team swiftly drafts a CAD‑accurate layout, conducts rigorous stress simulations, and presents a virtual prototype for your final approval. Once approved, production seamlessly moves to our precision‑spinning floor, where the Samthane‑coated Dyneema fibres are expertly braided, cut, and finished to your exact specifications. We also provide bespoke packaging solutions—including branded colour‑coded bags, custom‑printed cartons, or bulk pallets—ensuring the product arrives precisely as required for immediate deployment.

All custom runs are meticulously covered by our ISO 9001 quality‑management system, guaranteeing that every batch consistently meets the same rigorous standards as our standard stock.

Because AmSteel‑Blue’s core is both ultra‑light and exceptionally strong, it adapts seamlessly across a diverse spectrum of sectors. This performance is typical of UHMWPE ropes, which outperform traditional wire ropes in weight and durability. Off‑road recovery teams highly value its rapid‑handleability for winch lines, while yachting crews depend on this very same material for primary mooring, where its flotation capability acts as a crucial safety lifeline.

For a detailed comparison of synthetic fiber ropes versus traditional steel cables, see our steel cable vs. fiber rope analysis. This insight highlights why many professionals now prefer fiber solutions for both safety and cost efficiency.

Explore how our UHMWPE winch rope can replace steel cables in demanding applications here.

Trusted Partner

Beyond product excellence, iRopes safeguards your intellectual property, facilitates direct shipping to global ports, and backs every order with comprehensive IP protection and stringent on‑time delivery guarantees.

When you combine a line that is 80% lighter than a comparable steel cable with a supply chain that inherently respects your brand and confidentiality, the outcome is far more than just a rope—it's a potent strategic advantage. Whether you are scaling a remote cliff, anchoring a charter yacht, or recovering a 2‑tonne vehicle from challenging sandy terrain, iRopes possesses the expertise to tailor an AmSteel‑Blue solution that transforms that formidable challenge into a routine, efficiently managed operation.

Ready for a customised solution?

This article has demonstrated how the 12‑strand UHMWPE fibre rope, known as AmSteel‑Blue, delivers exceptional strength, minimal stretch, and natural flotation. This holds true whether it’s the feather‑light 1/8‑inch AmSteel‑Blue for camping and small‑craft rigging, or the powerhouse 3/8‑inch AmSteel‑Blue rope for off‑road winches and demanding heavy‑duty mooring applications. Coupled with iRopes’ ISO 9001‑certified OEM/ODM capabilities—which span custom lengths and colours to bespoke branded packaging—this versatile line can be meticulously tailored to meet any industry’s precise performance and branding requirements.

If you would like personalised advice on selecting the optimal size or a specific bespoke configuration, simply complete the form above, and our dedicated rope specialists will promptly work with you to develop the perfect solution.