Most consider steel cable unbeatable, yet UHMWPE (Ultra-High-Molecular-Weight Polyethylene) rope delivers up to 15 times the strength‑to‑weight ratio while being significantly lighter. It's the ultimate lightweight powerhouse for demanding applications.

What you’ll gain – ≈5 min read

- ✓ Cut load‑handling weight by up to 93% (e.g., replace a 100 kg steel line with a 7 kg UHMW rope).

- ✓ Extend service life up to 15 times longer than carbon‑steel, thanks to superior abrasion resistance.

- ✓ Operate safely across temperatures from –150 °C to +70 °C, virtually eliminating temperature‑related failures.

- ✓ Add colour, reflective strips, or glow‑in‑the‑dark elements without compromising tensile strength.

Imagine specifying rope for a marine winch. The default choice often remains steel cable, simply because that's what has always been used. However, the same load capacity can be achieved with a UHMWPE line that’s a fraction of the weight and, crucially, snaps back predictably instead of violently. In the sections that follow, we'll uncover how this intelligent switch can drastically reduce your project's weight, significantly boost safety, and cut long‑term operating costs.

Understanding UHMW: Material Basics and Terminology

Ultra‑high‑molecular‑weight polyethylene (UHMWPE) is a thermoplastic polymer renowned for its extraordinary strength‑to‑weight ratio. In industry, it's also known as HMPE (High-Modulus Polyethylene). You might also encounter the trade names Dyneema and Spectra on product labels. These terms all refer to the same high‑modulus fibre that has fundamentally reshaped performance in demanding applications worldwide.

Molecular structure and why ultra‑high molecular weight matters

Each fibre is composed of polyethylene chains stretching millions of repeat units long. This exceptional chain length allows the load to be distributed uniformly across the entire polymer structure. This uniform distribution is precisely what gives the material its famed tensile strength while maintaining a remarkably lightweight profile.

Ultra‑high‑molecular‑weight polyethylene’s strength comes from chains that are millions of repeat units long, allowing the fibres to share load uniformly.

Gel‑spinning: the manufacturing heart‑beat

The manufacturing process is crucial to UHMWPE's unique properties. During gel‑spinning, UHMWPE resin is first dissolved in a solvent to create a thick, viscous gel. This gel is then extruded through tiny nozzles and subsequently drawn at high speed. This rapid stretching process meticulously aligns the molecular chains, crystallising them into incredibly strong, tightly packed, high‑modulus fibres.

From fibre to rope and sheet

Because the same advanced polymer underpins both product forms, manufacturers can either spin these fine fibres into robust ropes or press them into flat panels. When UHMW is engineered into rope, the resulting UHMW rope offers unparalleled strength with minimal stretch. Conversely, a UHMW sheet provides a highly wear‑resistant, low‑friction surface, widely used for liners, guides, and protective barriers across numerous industries.

Key Advantages of UHMWPE Rope Over Traditional Materials

Building on the molecular fundamentals explained earlier, the rope format of UHMWPE translates these inherent properties into tangible performance gains that significantly surpass conventional steel cable and other synthetic alternatives. Its unique characteristics offer specific benefits in various demanding settings.

- Exceptional strength‑to‑weight ratio – UHMWPE rope is up to 15 times stronger than steel on a weight‑for‑weight basis, making it incredibly lightweight yet immensely powerful.

- Low stretch with superior abrasion and chemical resistance – Its elongation is limited to a mere 3‑4% at breaking load. It boasts abrasion resistance that exceeds carbon steel by approximately fifteenfold and is resistant to most common acids, bases, and oils.

- Buoyancy, wide temperature span, and a self‑lubricating safety profile – This rope floats on water, operates effectively across an extensive temperature range from –150 °C to +70 °C, and exhibits a smooth surface that naturally reduces friction. Crucially, if the rope fails, it recoils linearly. This offers a predictable safety advantage over the sudden, violent rupture of steel cables.

The predictable linear recoil of UHMWPE rope is far more than a mere comfort feature; it actively mitigates the “snap‑back” hazard that frequently injures personnel handling steel cables. In critical applications like offshore mooring or vehicle winch recovery, operators can rely on a controlled release of energy. This not only shortens shutdown times but also significantly lowers the risk of secondary damage, enhancing overall operational safety.

These combined attributes—unparalleled strength, exceptional durability, broad temperature resilience, buoyancy, and enhanced safety—make UHMWPE rope the preferred choice for demanding sectors. This includes offshore mooring, off‑road recovery, arborist rigging, and high‑performance sailing, where every kilogram saved and every safety margin secured genuinely counts. The performance gains are substantial and contribute directly to operational efficiency and crew well‑being.

Versatile Applications of UHMW Sheet Across Industries

Following our discussion on how UHMWPE rope consistently outperforms conventional materials, it’s equally important to explore the impressive capabilities of its flat‑panel form. The same high‑modulus polymer that delivers extraordinary strength in rope can also be pressed into sheets. These UHMW sheets then act as highly durable, low‑friction barriers across a wide array of industrial environments.

Beyond its remarkable resistance to abrasion, chemicals, and extreme temperatures, the UHMW sheet format excels in applications where a smooth, wear‑resistant surface is essential. When effectively paired with UHMW rope within a single system, the sheet expertly protects contact points while the rope handles the primary load. This creates a holistic solution that significantly reduces maintenance cycles and lowers overall project costs.

For deeper insight into how UHMWPE sheets complement rope systems, see our guide on high‑strength liners.

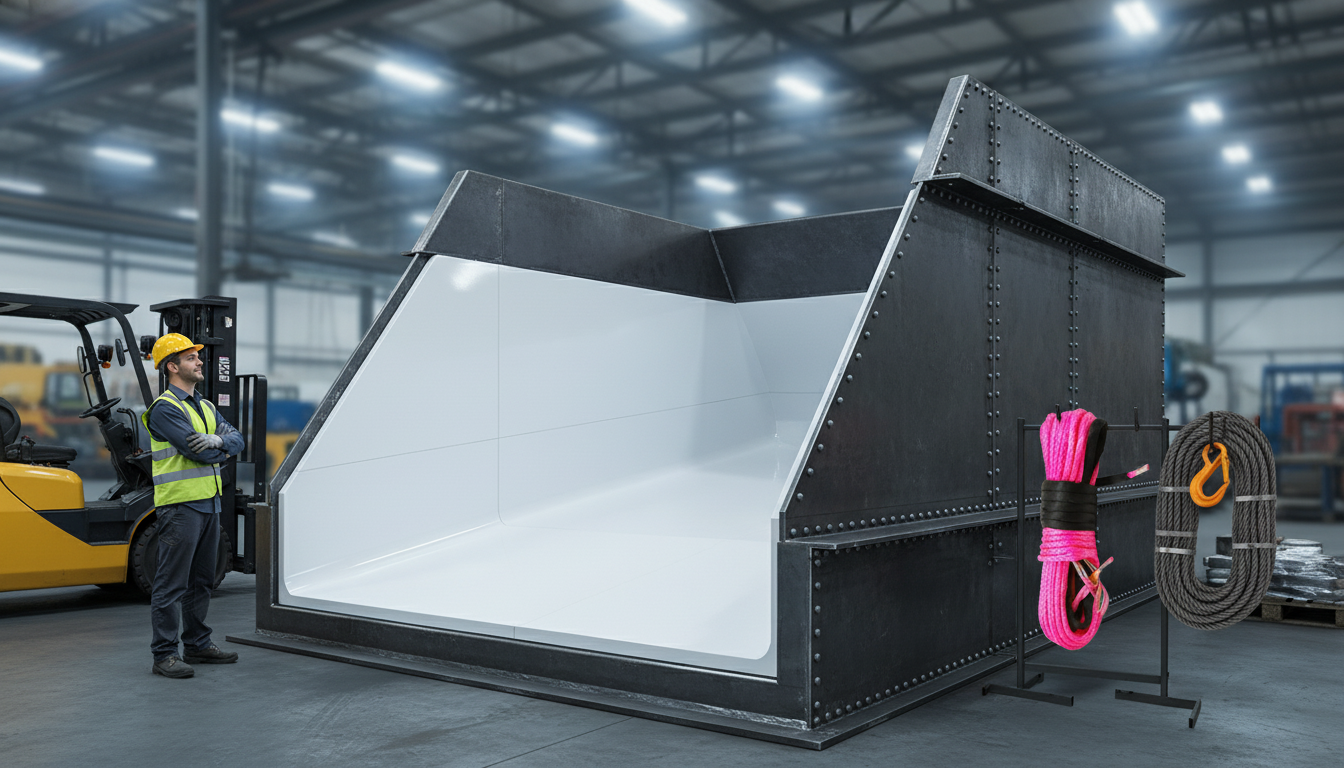

Industrial Liners

Protect chutes, hoppers, truck‑bed, and conveyor beds from abrasion and impact, thereby reducing maintenance downtime significantly.

Wear Strips & Guides

Serve effectively as star wheels, guide rails, and high‑speed conveyor components, resisting wear and maintaining dimensional stability.

Food & Medical

Non‑toxic, tasteless, and odourless, the sheet consistently meets stringent hygiene standards required for food processing lines and medical implants.

Rope‑Sheet Synergy

Combining resilient sheet liners with high‑strength UHMW rope creates complete handling systems where the rope bears load and the sheet effectively reduces friction.

Integrated Solutions

When a project demands both high‑strength load‑bearing lines and exceptionally low‑friction surfaces, pairing UHMW rope with an UHMW sheet delivers a unified, high-performance package. The rope efficiently handles tensile forces, while the sheet effectively safeguards contact points, resulting in longer service intervals and a lower total cost of ownership across the system.

Choosing iRopes for Custom UHMW Solutions and Partner Benefits

Building on the powerful synergy between UHMW rope and sheet applications, iRopes positions itself as a comprehensive, full‑service partner. We specialise in transforming a technical brief into a high‑performance product line perfectly tailored to your needs. Whether a marine operator requires a lightweight tow line or a food‑processing plant needs a hygienic liner, our end‑to‑end process ensures the material’s intrinsic strengths are fully realised in every solution.

iRopes’ comprehensive OEM and ODM capabilities commence with a collaborative design workshop. Here, clients can precisely choose the polymer grade—whether pure UHMW, HMPE blends, or specialised core types—then define crucial specifications like diameter, length, braid architecture for ropes, or sheet thickness for panels. Further customisation includes colour palettes, reflective strips, or glow‑in‑the‑dark additives, all incorporated without compromising tensile performance. This ensures each product not only meets functional requirements but also aligns perfectly with your brand guidelines or specific safety codes.

Every batch produced by iRopes undergoes a rigorous testing regime that adheres to stringent industry standards, including ISO 10325 and OCIMF guidelines. Laboratory‑grade tensile, elongation, and abrasion tests are meticulously logged under our ISO 9001‑certified quality management system. This provides a transparent, traceable data sheet for each custom production run. Furthermore, iRopes provides robust intellectual property (IP) protection, contractually safeguarding client‑owned designs and ensuring that all proprietary specifications remain confidential from initial resin selection through to final packaging and delivery.

We achieve cost competitiveness through strategic, high‑volume polymer sourcing and highly efficient lean‑manufacturing practices. iRopes offers transparent pricing tiers that are carefully structured based on order size, while consolidated pallet shipments significantly reduce overall freight expenses. With a well‑established network of trusted global carriers, iRopes guarantees punctual, door‑to‑door delivery. This ensures your projects remain on schedule and minimises downtime for critical operations, anywhere in the world.

Tailored Manufacturing

From concept to finished product

Materials

Select UHMW, HMPE, or blended cores to meet specific strength and wear requirements for optimal performance.

Dimensions

Precisely specify diameter, length, braid pattern, or sheet thickness for exact load capacity and application fit.

Finishes

Add custom colour, reflective strips, or glow‑in‑the‑dark elements that align perfectly with your branding or crucial safety standards.

Our expertise aligns with industry leaders; learn more about the top HMPE rope manufacturers worldwide to understand the broader market landscape.

Assurance & Delivery

Quality you can trust

ISO 9001

Our full‑system quality management guarantees each product meets stringent, documented performance criteria consistently.

IP Protection

Robust legal safeguards preserve your proprietary designs and innovations throughout the entire development and production process.

Logistics

Benefit from competitive pricing, consolidated pallets, and efficient door‑to‑door shipping that keeps your projects on schedule worldwide.

Discover why UHMWPE consistently outperforms traditional wire rope in lifting applications, delivering higher strength with lower weight and cost.

Ready to elevate your project? Request a tailored quote today and let iRopes engineer the perfect UHMW rope or sheet solution for your specific application.

Get a Tailored UHMW Solution for Your Project

Throughout this article, you've seen how the versatile UHMW material delivers exceptional strength‑to‑weight, minimal stretch, superior chemical resistance, and natural buoyancy. These properties make it ideal for critical applications such as offshore mooring, off‑road recovery, arborist rigging, and high‑performance sailing. By combining customised UHMW rope with durable UHMW sheet liners, manufacturers can create integrated handling systems that not only protect contact points but also maximise overall load capacity and operational efficiency.

If you'd like personalised guidance on selecting the right product or adding custom features, simply use the form above to connect with us. Our experienced engineers will design a precise, high‑performance solution that perfectly fits your exact needs and specifications.