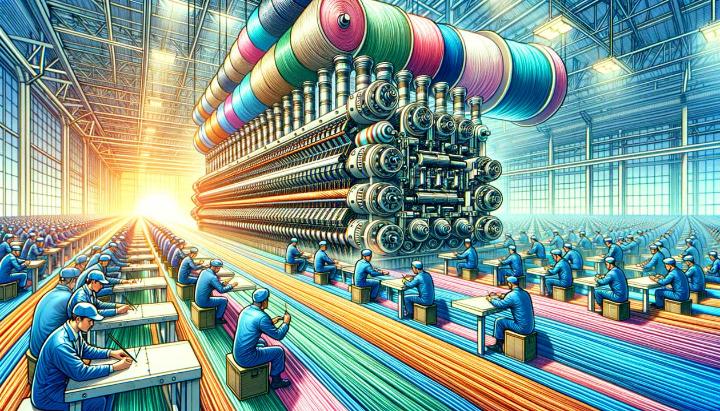

Have you ever wondered how a simple twist of fibres can become the lifeline that keeps a climber safe or the sturdy support that secures a ship to its moorings? At iRopes, we've mastered the art of transforming raw materials into high-performance ropes and cords that power industries and adventures alike. As a leading manufacturer of braided ropes, we're not just crafting products; we're weaving solutions that elevate safety, efficiency, and innovation across diverse sectors.

Our journey begins with an intricate dance of strands, where cutting-edge braiding techniques meet time-honoured craftsmanship. From the double braid construction that offers unparalleled strength to the plaited rope technology that withstands the harshest environments, iRopes stands at the forefront of rope and cord innovation. But why does mastering these techniques matter? Because in the world of ropes and cords, precision can mean the difference between success and failure, safety and risk.

In this post, we'll unravel the secrets behind our advanced braiding methods, explore the versatility of cord and twine in both industrial and creative applications, and showcase why iRopes has become the trusted supplier for businesses worldwide. Whether you're scaling mountains, securing cargo, or crafting intricate designs, understanding the nuances of rope and cord techniques is your first step towards unlocking a world of possibilities. Join us as we delve into the art and science of rope making, and discover how iRopes is setting new standards in quality, customisation, and performance.

Understanding Rope and Cord Basics

When it comes to mastering rope and cord techniques, it's essential to start with the fundamentals. As an avid climber and sailing enthusiast, I've learned that understanding the basics can make all the difference in your rope-related adventures. Let's dive into the world of ropes and cords, exploring their materials, construction, and key properties.

Types of Rope and Cord Materials

Have you ever wondered what your rope is made of? The material choice can significantly impact a rope's performance and durability. Here's a quick rundown of common rope materials:

- Synthetic fibres: Polyester, nylon, and polypropylene are popular choices for their strength and resistance to water damage.

- Natural fibres: Cotton, hemp, and manila offer a traditional feel and are often used in decorative or historical applications.

- High-performance materials: Kevlar and Dyneema provide exceptional strength-to-weight ratios for specialised uses.

Each material has its unique properties, making it suitable for different tasks. For instance, I once used a nylon rope for rock climbing, and its slight stretch provided a comfortable catch during falls.

Rope Construction and Properties

The way a rope is constructed plays a crucial role in its performance. Let's explore two main types:

- Braided ropes: These ropes are made by interweaving multiple strands, resulting in a smooth, round profile. They're typically more flexible and easier to handle.

- Twisted ropes: Constructed by twisting fibres together, these ropes are often stronger but can be prone to unravelling if not properly maintained.

When choosing a rope, consider these key properties:

- Tensile strength: The maximum load a rope can bear before breaking.

- UV resistance: Important for ropes used outdoors to prevent degradation from sunlight.

- Abrasion resistance: Crucial for ropes that will encounter rough surfaces or frequent use.

Selecting the Right Rope for Specific Tasks

Choosing the appropriate rope for your needs can be daunting, but it's crucial for safety and efficiency. Consider these factors:

- Intended use: Are you climbing, sailing, or using it for general utility?

- Environment: Will the rope be exposed to water, UV rays, or abrasive surfaces?

- Required strength: What's the maximum load the rope needs to support?

Remember, a rope that's perfect for one task might be unsuitable for another. For example, the dynamic rope I use for rock climbing would be a poor choice for a static load in construction work.

Always prioritise safety when selecting and using ropes. When in doubt, consult with experts or manufacturers to ensure you're using the right rope for your specific needs.

Understanding these rope and cord basics is your first step towards mastering various techniques. As you continue to explore and experiment with different ropes, you'll develop an intuitive sense of which type is best suited for each task. Remember, practice makes perfect, so don't be afraid to get hands-on with your newfound knowledge!

Mastering Rope Braiding Techniques: iRopes' Expertise

At iRopes, we've been perfecting the art of rope braiding for over two decades. Our journey began with a simple passion for creating high-quality ropes, and today, we're proud to be at the forefront of rope manufacturing technology. But what exactly sets our braiding techniques apart?

Advanced Braiding Methods for High-Performance Ropes

Imagine a rope that's not just strong, but also flexible, durable, and tailored to your specific needs. That's what our advanced braiding methods aim to achieve. Let me walk you through some of our cutting-edge techniques:

- Double braid construction: This method combines a braided core with a braided cover, resulting in ropes with exceptional strength and low stretch properties. Perfect for applications where stability is crucial, such as in yacht rigging or industrial lifting.

- Plaited rope technology: By interweaving multiple strands in a complex pattern, we create ropes with a smooth surface and excellent resistance to abrasion. I've seen these ropes perform brilliantly in harsh marine environments.

- Parallel core braiding: This technique allows us to produce ropes with minimal stretch and maximum strength-to-weight ratio. It's a game-changer for climbers and arborists who need reliable, lightweight equipment.

The Science Behind Rope Construction and Durability

Have you ever wondered why some ropes last longer than others? The secret lies in the intricate relationship between braiding patterns and rope strength. At iRopes, we've dedicated countless hours to researching and perfecting this science.

Our team of engineers constantly experiments with different braiding patterns, adjusting factors like strand count, braid angle, and tension. We've found that even small changes in these parameters can significantly impact a rope's performance characteristics.

For instance, a tighter braid angle generally results in a more abrasion-resistant rope, while a looser braid offers more flexibility. It's this level of detail that allows us to create ropes tailored to specific applications, whether it's a dynamic climbing rope or a static mooring line.

Did you know? The choice of synthetic cordage materials plays a crucial role in the braiding process. At iRopes, we carefully select materials like high-tenacity polyester and ultra-high-molecular-weight polyethylene (UHMWPE) to ensure optimal performance in our braided ropes.

But our commitment to quality doesn't stop at the braiding process. We've invested heavily in state-of-the-art testing facilities to rigorously evaluate our ropes under various conditions. This allows us to continuously refine our braiding techniques and push the boundaries of rope performance.

As we look to the future, our R&D team is exploring exciting new frontiers in rope construction. From incorporating smart fibres for real-time load monitoring to developing bio-based synthetic materials, we're always striving to innovate and improve.

At iRopes, we believe that mastering technique starts with selecting the right rope for reliable off-road recovery. It's this dedication to continuous improvement and innovation that allows us to provide our customers with the highest quality braided ropes for any application. Whether you're scaling a mountain, mooring a yacht, or securing a heavy load, you can trust in the expertise and craftsmanship that goes into every iRopes product.

Versatility of Cord and Twine: Endless Applications

When it comes to cord and twine, the possibilities are truly endless. As a DIY enthusiast and gardening aficionado, I've found myself reaching for these versatile materials more times than I can count. Whether you're a crafty hobbyist or a professional in need of reliable binding solutions, understanding the diverse applications of cord and twine can be a game-changer.

Natural vs Synthetic: Choosing the Right Material

The age-old debate of natural versus synthetic materials takes an interesting turn when it comes to cord and twine. Let's break it down:

- Natural fibres: Jute and cotton twines offer a rustic charm and are biodegradable, making them perfect for eco-conscious projects.

- Synthetic options: Polypropylene and nylon cords provide superior strength and weather resistance, ideal for outdoor or heavy-duty applications.

I remember using jute twine for a macramé plant hanger project last summer. Not only did it look stunning, but I also felt good knowing it was an environmentally friendly choice. On the flip side, when I needed to secure a tarp during a particularly windy camping trip, synthetic cord was my go-to for its unmatched durability.

DIY Projects and Crafts: Creative Uses for Twine

The world of DIY and crafts has embraced twine with open arms. Here are some popular applications that might inspire your next project:

- Rustic home decor: Wrap mason jars with jute twine for charming candle holders or vases.

- Garden helpers: Use cotton twine to train climbing plants or tie up tomato vines.

- Gift wrapping: Add a personal touch to presents with colourful twine bows.

Want to try a quick and easy twine project? Here's a simple tutorial for a twine-wrapped picture frame:

- Choose a wooden frame and your preferred twine colour.

- Apply a thin layer of craft glue to one side of the frame.

- Starting at one corner, wrap the twine tightly around the frame, ensuring each wrap sits snugly against the previous one.

- Continue wrapping until the entire frame is covered, then secure the end with a dab of glue.

- Allow to dry completely before inserting your favourite photo.

This simple project showcases how a humble material like twine can transform everyday objects into eye-catching pieces of decor.

Industrial and Commercial Applications of Cord

While twine shines in the world of crafts, cord takes center stage in industrial settings. Here's where you'll find cord making a difference:

- Construction: Nylon cords are used for layout and measuring tasks on job sites.

- Agriculture: Polypropylene cord helps in baling hay and securing loads.

- Marine industry: Specialised marine cords resist saltwater degradation for long-lasting performance.

At iRopes, we understand the diverse needs of our customers. That's why we offer a comprehensive range of cord and twine products, from delicate cotton twines for crafting to heavy-duty synthetic cords for industrial use. We have dedicated experts who master every pattern, ensuring that your cord solutions meet the highest standards of performance.

Did you know? The strength of a cord isn't just about its material. The braiding technique used in construction plays a crucial role in determining its load-bearing capacity and durability.

As we've explored, the versatility of cord and twine is truly remarkable. From crafting beautiful home decor to securing heavy loads in industrial settings, these humble materials prove their worth time and time again. Next time you're faced with a binding, tying, or decorative challenge, consider reaching for cord or twine – you might be surprised at just how capable they can be!

iRopes: Your Trusted Rope and Cord Supplier

When it comes to high-quality ropes and cords, iRopes stands out as a beacon of excellence in the industry. As a leading rope manufacturer based in China, we've spent years perfecting our craft, ensuring that every product that leaves our facility meets the highest standards of quality and safety. But what makes iRopes truly special? Let's dive in and explore why we've become the go-to supplier for businesses across various industries.

High-Performance Ropes for Various Industries

At iRopes, we understand that different industries have unique rope requirements. That's why we've developed a diverse range of high-performance ropes tailored to specific needs:

- Marine-grade ropes: Designed to withstand harsh saltwater environments, these ropes are perfect for yachting, commercial fishing, and offshore operations.

- Industrial-strength cords: Engineered for heavy-duty applications in construction, mining, and manufacturing sectors.

- Specialized climbing ropes: Crafted with precision for rock climbing, mountaineering, and arborist work, ensuring safety at great heights.

- Utility ropes and twines: Versatile options for everyday use in agriculture, packaging, and general-purpose applications.

Each rope type is meticulously crafted using our advanced braiding techniques, resulting in products that exceed industry standards for strength, durability, and performance.

Why Choose iRopes as Your Reliable Supplier

Choosing the right rope supplier can make all the difference in your operations. Here's why iRopes stands out from the competition:

- Unparalleled expertise: With over two decades of experience in rope manufacturing, our team of experts brings a wealth of knowledge to every project.

- Cutting-edge research and development: We're constantly pushing the boundaries of rope technology, investing in innovative materials and braiding techniques to stay ahead of the curve.

- Custom solutions: Need a rope with specific properties? Our team works closely with clients to develop bespoke rope solutions tailored to their unique requirements.

- Rigorous quality control: Every rope undergoes stringent testing to ensure it meets our high standards for safety and performance.

- Exceptional customer support: From initial inquiry to after-sales service, our dedicated team is always ready to assist you with any questions or concerns.

But don't just take our word for it. Here's what one of our long-time customers had to say:

"We've been using iRopes products for our offshore operations for over five years now. The quality and reliability of their ropes are unmatched, and their custom solutions have helped us overcome some of our toughest challenges. iRopes isn't just a supplier; they're a true partner in our success."

At iRopes, we're not just manufacturing ropes; we're crafting solutions that help businesses across industries operate more safely and efficiently. Whether you're securing heavy loads, scaling mountains, or navigating rough seas, you can trust iRopes to provide the high-performance ropes and cords you need.

Ready to experience the iRopes difference? Contact us today to discuss your rope and cord requirements, and let's work together to find the perfect solution for your needs. If you're interested in innovative synthetic rope solutions, we've got you covered. With iRopes as your trusted supplier, you're not just buying a product – you're investing in quality, safety, and peace of mind.

Unlock the Expertise of iRopes for Superior Rope and Cord Solutions

Explore how iRopes, a premier rope manufacturer from China, masters advanced braiding techniques to produce high-quality rope and cord products customised for various applications. Delve into our diverse range, from off-road and marine-grade ropes to versatile cord and twine, perfect for businesses seeking top-notch rope and cord suppliers. Our commitment to excellence, innovation, and customer satisfaction ensures that all our products meet rigorous quality standards. Fill in the form above to discover tailor-made solutions that align perfectly with your needs and elevate your projects to new heights with iRopes.