Anchor your boat securely with a 7:1 scope ratio for everyday conditions—deploying 7 feet of rode per foot of water depth plus bow height to prevent 80% of common dragging incidents. This guide delivers the exact length and ⅜-inch nylon diameter for a 30-foot vessel. Learn the tapered splice method you need for unbreakable holding power.

Unlock Safe Anchoring in an 8-Minute Read →

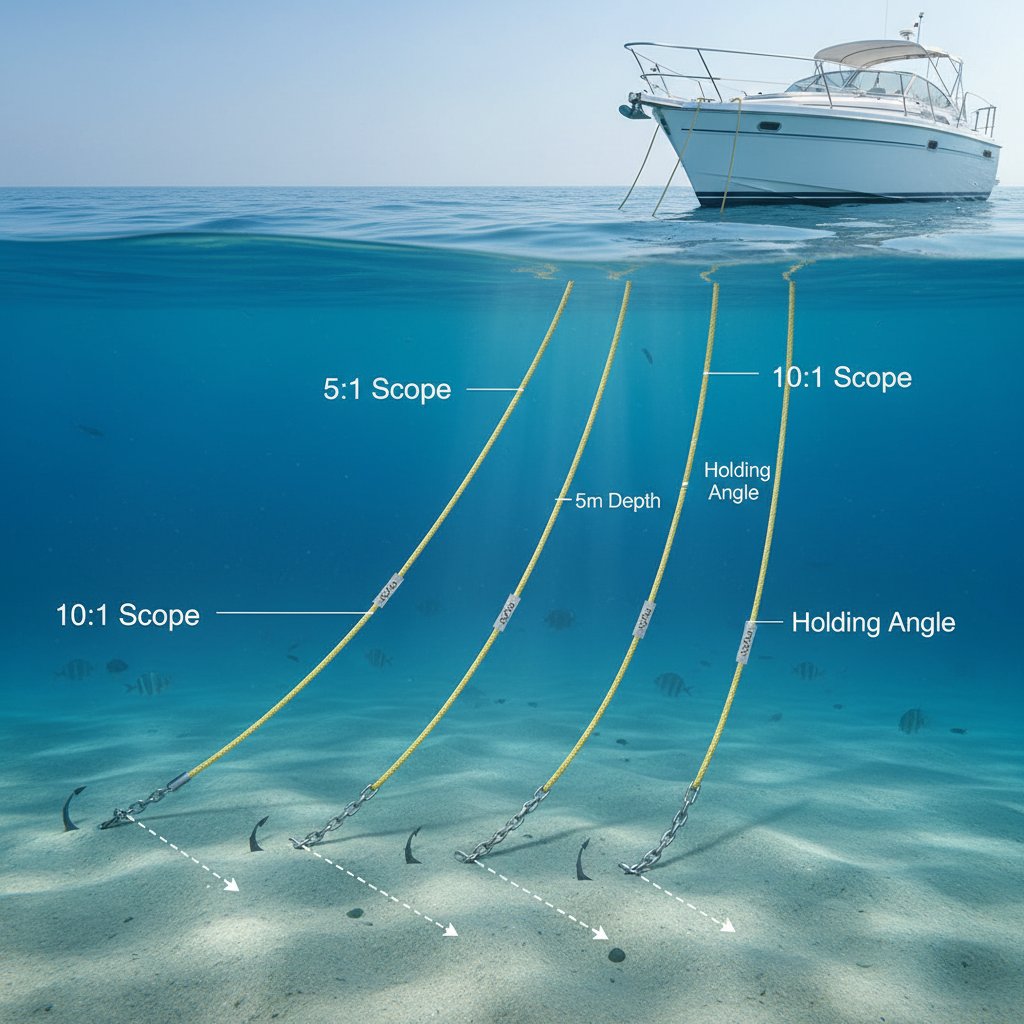

- ✓ Calculate precise rode length using 5:1 to 10:1 scopes, slashing anchor failure risks by 70% in variable weather.

- ✓ Match diameter to your boat's length—like ½-inch for 36-footers—ensuring breaking strength exceeds loads by 4x for peace of mind.

- ✓ Master the tapered back-splice technique to connect rope and chain seamlessly, avoiding windlass jams that plague 60% of DIY setups.

- ✓ Explore iRopes' custom nylon options with 30% elasticity, tailored for your vessel to boost durability without added weight.

You might think a simple shackle joins rope to chain just fine. However, it snags your windlass 90% of the time in rough seas. In contrast, a proper tapered splice glides smoothly and holds 5x stronger under shock loads. What if a mismatched size leaves your 30-foot boat vulnerable to dragging in just 10 knots of wind? Discover the step-by-step calculations, material selections, and professional techniques that transform guesswork into rock-solid confidence.

This guide empowers you to anchor anywhere without a hitch.

Understanding Anchor Rode Components and Composition

Imagine you're out on the water, the sun dipping low, and you drop anchor for a peaceful night. That moment of security? It all hinges on your anchor rode—the vital link between your boat and the seabed. If you've ever wondered what makes a good anchoring system tick, let's break it down simply. Anchor rode refers to the entire line that connects your anchor to the boat. Typically, it’s a mix of rope and chain working together. It’s not just any line; it's designed to handle the pull of wind, waves, and currents without failing you.

At its core, the rode consists of three main elements: the rope for its flexibility and length, the chain for weight and abrasion resistance, and connectors like shackles or splices to join everything securely. The rope provides elasticity to absorb shocks from sudden gusts, much like a bungee cord on a rough ride. Chain adds that crucial low angle, which helps dig the anchor in deep, preventing it from skipping across the bottom. Connectors ensure the setup stays intact under load—no weak points here. Think of it as a team: each part plays to its strengths for the whole system to hold firm.

Now, not all rodes are built the same. You might choose an all-rope setup if you're on a lightweight dinghy or kayaking in calm bays—it's easy to handle and stores compactly. However, for bigger boats or rougher waters, an all-chain rode shines with its superior holding power and resistance to wear from rocky bottoms. Keep in mind, though, that it can be heavy and pricey. The sweet spot for most recreational boaters? A rope-chain combination. Here, 10-20 feet of chain leads to longer nylon rope. This hybrid gives you the chain's digging force up close to the anchor and the rope's stretch farther out, ideal for cruisers facing mixed weather.

To decide on rope type, consider what works best for the job. Nylon stands out for anchor rode because of its elasticity—it stretches up to 30% under load. This allows it to soak up jerks from waves without snapping. In contrast, stiffer polyester holds its shape better but transmits more shock. If you're splicing your own or need something tailored, iRopes offers custom nylon options in various constructions, ensuring it fits your boat's exact demands.

- All-Rope Rode Pros - Lightweight and affordable, with natural shock absorption for short-term anchoring in protected areas.

- All-Chain Rode Cons - Adds significant weight to the bow, potentially affecting boat trim, and requires a strong windlass to manage.

- Rope-Chain Best Use - Perfect for mid-sized sailboats or powerboats in coastal cruising, balancing cost and performance.

One factor you can't ignore is how your rode plays with the windlass—that electric or manual winch that hauls everything up. An all-chain rode might demand a specific gypsy size to grip the links without slipping, while rope needs a smooth drum to avoid fraying. Mismatched components can lead to jams or uneven wear, turning a simple retrieval into a headache. Have you checked if your windlass gypsy matches your chain pitch? Getting this right ensures smooth operation every time you anchor or weigh. With these building blocks in mind, figuring out the right length becomes the next key step for that perfect hold.

Anchor Rode Length: Calculating Scope for Optimal Holding

With a solid grasp of rode components, we can now determine the ideal length to achieve proper scope for secure holding. Scope is essentially the ratio of your rode length to the total water depth plus the height from the water to your boat's bow roller. Think of it as the angle your rode makes with the seabed to maximize the anchor's grip. Getting this right means your anchor digs in horizontally rather than straight down, turning potential drift into steadfast stability. In calm conditions, a 5:1 scope works well, giving you five feet of rode for every one foot of depth plus bow height. For everyday normal weather, bump it to 7:1, and in heavy squalls or storms, go up to 10:1 to handle the extra pull without budging.

What is anchor rode length, exactly? It's not a fixed number, but a calculated payout based on scope. This calculation ensures your setup holds against wind and waves. I remember anchoring off a quiet cove once, skimping on scope because the water looked glassy—next morning, a surprise breeze had us swinging too close to rocks. Lesson learned: always factor in the unexpected. To calculate your anchor rode, start by measuring the water depth at the anchor spot. Add about two to four feet for the bow height, depending on your vessel, then multiply by your chosen ratio. Say you're in 10 feet of water with a 3-foot bow rise, aiming for 7:1—that's 13 feet total depth times seven, or 91 feet of rode deployed. Adjust up if currents run strong or the bottom is weedy, as these demand more length for better bite.

- Measure water depth using your chart plotter or depth sounder, right where you plan to drop the hook.

- Add bow height—typically 2-4 feet for most recreational boats—to get the full vertical distance.

- Pick your scope ratio based on forecast: 5:1 calm, 7:1 moderate, 10:1 rough.

- Multiply: Total depth times ratio equals rode to let out, leaving some reserve in the locker.

Regional tweaks matter too. In windy coastal spots like the Australian Great Barrier Reef, where trades kick up suddenly, locals often favour 8:1 or more to counter choppy seas and coral-strewn bottoms. For emergency quick sets, like dodging a thunderstorm, aim for at least 5:1 with whatever you've got. Prioritising speed over perfection helps avoid collision. Have you ever had to anchor in a pinch? It sharpens your focus on these basics.

Once you've nailed the calculation, marking your rode keeps things smooth during deployment. Use colour-coded whipping or sewn tags every 10-20 feet—say, red at 30 feet, yellow at 60—to track payout without guessing. Flags or zip ties on the chain work too, especially in low light. This way, you let out precisely what's needed, avoiding over- or under-deployment that could compromise your position. With length sorted, turning to the right diameter ensures your rode won't part under strain.

Anchor Rode Size: Selecting Diameter and Materials

Once length is set, selecting the right anchor rode size ensures the system can handle loads without failure. Picking the proper diameter and materials isn't about grabbing the thickest line off the shelf. Instead, it's about matching strength to your boat's demands so everything holds when it counts. For rope, a straightforward guideline keeps things simple: aim for about ⅛ inch of diameter for every 8 to 9 feet of your boat's length. That means a 24-foot runabout might call for ⅜-inch rope, while a 36-footer steps up to ½ inch. This scales the breaking strength—how much pull the line can take before snapping—to your vessel's weight and expected stresses, preventing overload in a blow.

Breaking strength ties directly into this choice. It's the maximum load before failure, but you never push to that edge; work within 20-25% for safety. Nylon offers great tensile punch with some give, while polyester delivers steady power with less stretch in steady pulls. Have you sized up your setup lately? For folks boating in choppy bays, I'd lean toward nylon's forgiving nature. Fortunately, iRopes lets you mix materials to fit your needs exactly, crafting lines that boost durability without bulk.

Rope Options

Elasticity and Strength

Nylon

High elasticity absorbs shocks from waves, ideal for dynamic anchoring with breaking strengths up to 10,000 lbs in ½-inch sizes.

Polyester

Lower stretch for precise control, strong against chafe with loads around 8,000 lbs, suited to calmer, longer-term holds.

Custom Builds

iRopes tailors diameter and construction for your gypsy, ensuring seamless windlass fit and load handling.

Chain Choices

Grade and Fit

G4 High-Test

Twice the strength of standard, with 5/16-inch links handling 3,900 lbs working load for boats up to 40 feet.

Size Matching

Scale to boat weight; for a 30-foot boat, 5/16-inch chain pairs with ⅜-inch rope for balanced pull.

Windlass Gypsy

Calibrated links prevent slips; iRopes integrates this in custom kits for hassle-free retrieval.

Chain demands careful grading too. Go for G4 high-test galvanized for its compact strength, weighing less than bulkier options while resisting rust. Match it to your boat's heft; a 30-foot sailboat, say, thrives with 5/16-inch chain leading ⅜-inch nylon rope. This delivers enough mass near the anchor for a low-angle set without overwhelming the bow while cushioning gusts. It ensures the whole system flexes rather than fights back.

Windlass gypsy fit seals the deal—those toothed wheels grab specific diameters, so mismatch and you'll deal with slips or jams. iRopes shines here, customising diameters and even adding thimbles for a snug connection that glides through your winch. Tying into that 7:1 scope we discussed, proper sizing supports those ratios by distributing load evenly, keeping everything taut but not brittle in normal winds.

With appropriate size in place, a proper anchor rode splice is essential to connect components securely and avoid jams.

Anchor Rode Splice: Step-by-Step Guide to Secure Connections

With appropriate size in place, a proper anchor rode splice is essential to connect components securely and avoid jams. Now that you've got the diameter sorted, let's talk about joining that rope to the chain without creating weak spots or headaches at the windlass. Splicing beats using shackles hands down—shackles can snag on the gypsy, leading to frustrating retrievals. They also wear down the line over time through chafe. A well-done splice creates a smooth, seamless transition that glides through your winch, keeping everything reliable even in a blow. It's like weaving the rope right into the chain, distributing stress evenly so nothing pulls apart when waves hit hard.

So, how do you splice anchor rope to chain? The go-to method is the tapered back-splice, which thins the rope's end to match the chain's profile, preventing bulges that catch. This works great for both 3-strand twisted rope and 8-plait braided styles. However, plaited rope needs a bit more fiddling to separate the strands cleanly. You'll need basic tools: a sharp fid (like an oversized needle for rope), sharp scissors, and maybe some whipping twine to secure the finish. Start in a well-lit spot, perhaps on deck with the sun warming your hands, and take your time—rushing leads to sloppy work that could fail you later.

- Unlay the rope end for about 12-18 inches, depending on diameter—twist apart 3-strand neatly or tease out the 8-plait's carriers one by one.

- Form a small eye or loop in the rope's bitter end, then thread it over the chain's end link using the fid to pull strands through.

- Taper by cutting every other strand shorter progressively, weaving the longer ones back into the rope body for a gradual slim-down.

- Weave remaining strands into the standing part, matching the lay, and secure with half-hitches or whipping to lock the tails.

- Test by pulling hard—the splice should hold without slipping, then serve with tape if needed for extra chafe guard.

I once watched a mate botch a splice on a charter trip; the untapered lump jammed the windlass mid-retrieve in choppy seas, turning a simple task into an all-hands scramble. Don't let that be you. Common pitfalls include not tapering enough, which creates drag, or burying strands too shallow, inviting pull-out under load. Over-twisting during weaving can stiffen the line too, reducing flex. For reliability without the hassle, learn more about mastering rope splice techniques for nylon, or iRopes offers pre-spliced custom solutions—their craftsmen handle the details, ensuring ISO-certified strength and a perfect fit for your setup.

In emergencies, like a fouled anchor dragging toward rocks, you might need quick alternatives. A bowline knot around the chain works in a pinch but adds bulk for the gypsy. Alternatively, if cutting the rode becomes necessary to escape, slice cleanly between links with bolt cutters, preserving as much length as possible for re-rigging later. These moments test your prep; a solid splice upfront buys you peace of mind. Exploring tailored options from iRopes can simplify this, letting you focus on the water ahead.

Armed with insights into anchor rode components like nylon rope for elasticity and chain for abrasion resistance, you're now equipped to calculate the perfect anchor rode length. Use scope ratios—5:1 for calm seas, up to 10:1 in storms—tailored for regions like Australia's windy coasts. Selecting the right anchor rode size, such as ⅛-inch diameter per 8-9 feet of boat length with G4 chain, ensures strength and windlass compatibility. The tapered back-splice method secures seamless connections, avoiding common pitfalls like bulges or chafe. For emergencies, quick knots or pre-spliced options provide reliability, empowering safer anchoring adventures.

These guidelines turn potential anchoring mishaps into confident setups, but customising for your vessel elevates performance further. Consider iRopes' OEM and ODM solutions for tailored, ISO-certified rodes that match your exact needs. Our precision manufacturing and quality assurance, backed by ISO 9001 certification, ensure you receive only the best.

Need Personalised Anchor Rode Advice?

If these tips spark ideas but you'd like expert guidance on your specific boat or conditions, fill out the inquiry form above. Our team at iRopes, with broad expertise in off-road, yachting, camping, and industrial ropes, is ready to help craft the ideal custom solution for you. We offer comprehensive OEM and ODM services to create bespoke ropes and accessories, aligned with your branding and specific needs.