Have you ever found yourself in a bind, quite literally, wondering which rope to trust for your critical tasks? Enter the unsung hero of the cordage world: braided nylon rope. This remarkable invention has revolutionised industries from maritime to mountaineering, offering a perfect blend of strength, versatility, and ease of use.

In this ultimate guide, we'll unravel the myriad advantages of braided nylon rope, with a special focus on the powerhouse that is 1" braided nylon rope. Whether you're a seasoned professional or a weekend warrior, understanding the unique properties of this essential tool can be the difference between success and failure in your endeavours.

From its superior strength that defies its lightweight nature to its ability to perform in the most challenging environments, braided nylon rope has become the go-to choice for those who demand the best. Join us as we explore how this versatile cord can elevate your projects, enhance your safety, and potentially save you from sticky situations. Prepare to be amazed by the hidden potential of this seemingly simple tool – your next adventure or project might just depend on it!

Superior Strength and Durability of Braided Nylon Rope

When it comes to choosing the right rope for your needs, braided nylon rope stands out as a powerhouse of strength and durability. As an avid sailor and rock climbing enthusiast, I've had my fair share of experiences with various rope materials, and I can confidently say that braided nylon rope is in a league of its own.

Unique Properties of Nylon Fiber

At the heart of braided nylon rope's impressive performance lies its high-tenacity nylon fiber composition. This remarkable material boasts an exceptional strength-to-weight ratio, making it ideal for heavy-duty applications without adding unnecessary bulk. In my years of maritime adventures, I've witnessed nylon ropes withstand tremendous loads that would have snapped lesser materials in an instant.

But what truly sets nylon apart is its superior stretch and shock absorption capabilities. Picture this: you're mooring your boat in choppy waters, and suddenly, a large wave hits. The nylon rope's ability to stretch and absorb the shock can mean the difference between a secure mooring and a potential disaster.

Advantages of Braided Construction

The braided construction of nylon rope takes its inherent strength to the next level. By interweaving multiple strands, manufacturers create a rope that's not only stronger but also more resistant to abrasion and wear. I've seen braided nylon ropes outlast their twisted counterparts by years, even in harsh marine environments.

Did You Know?

Braided nylon rope retains 85-90% of its strength when wet!

The smooth surface of braided nylon rope also makes it ideal for use with pulley systems. Whether you're hoisting a sail or setting up a complex rigging system, the rope glides effortlessly, reducing friction and wear.

Applications and Uses

The superior strength and durability of braided nylon rope make it the go-to choice for a wide range of industries and applications. In the marine world, it's used for everything from mooring and anchoring to sail control lines. Its resistance to UV rays and saltwater makes it perfect for long-term outdoor use.

In the industrial sector, braided nylon rope is a workhorse for lifting, towing, and securing heavy loads. Its shock-absorbing properties make it particularly valuable in scenarios where sudden load shifts could be dangerous. To understand which type of rope best suits your needs, read more on Synthetic vs Natural Fiber Ropes: Which is Best?.

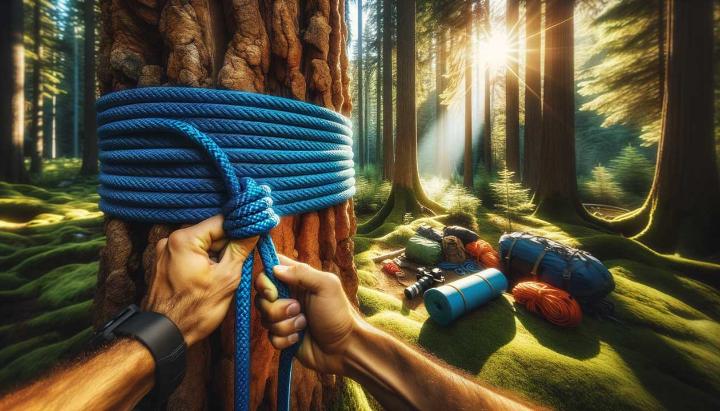

For outdoor enthusiasts, this rope is a reliable companion for climbing, rappelling, and even creating makeshift shelters. Its versatility and durability make it an essential item in any adventurer's kit.

In conclusion, the superior strength and durability of braided nylon rope make it an invaluable asset across various industries and activities. Its unique properties, enhanced by braided construction, ensure that it can handle the toughest challenges while maintaining its integrity over time. Whether you're out on the open sea, scaling a cliff face, or working in a demanding industrial environment, braided nylon rope is a choice you can trust.

Lightweight and Easy Handling of 1" Braided Nylon Rope

As an avid outdoorsman and DIY enthusiast, I've had my fair share of experiences with various types of ropes. But when it comes to versatility and ease of use, 1" braided nylon rope stands head and shoulders above the rest. Let's dive into what makes this rope a game-changer for both professionals and hobbyists alike.

Benefits of Lightweight Nylon Rope

One of the most striking features of 1" braided nylon rope is its impressive strength-to-weight ratio. Despite its robust capabilities, this rope feels surprisingly light in your hands. I remember the first time I replaced my old, heavy manila rope with a nylon alternative - the difference was night and day!

- Exceptional portability: The lightweight design means you can carry longer lengths without breaking a sweat, perfect for backpacking or extended boating trips.

- Improved manoeuvrability: Whether you're rigging a tarp or securing cargo, the rope's light weight allows for quick and precise adjustments.

- Reduced fatigue: During long-duration tasks, the lighter rope means less strain on your hands and arms, allowing you to work more efficiently.

Have you ever found yourself struggling with a heavy rope during a crucial moment? With 1" braided nylon rope, those days are behind you. For more insights on selecting and maintaining high-quality ropes, explore our Essential Tips for Choosing and Maintaining Boat Anchor Ropes.

Handling Techniques for Braided Rope

The supple nature of braided nylon rope makes it a joy to handle, but proper techniques can enhance your experience even further. Here are some tips I've picked up over the years:

Always coil your rope in a figure-eight pattern to prevent twists and tangles. This simple habit can save you countless headaches in the field!

When it comes to knot tying, the flexibility of braided nylon rope truly shines. Its smooth surface allows knots to cinch down tightly, while still being easy to untie when needed. I've found the bowline knot to be particularly effective with this type of rope - it's strong, reliable, and doesn't jam easily.

For storage, consider using a rope bag or a simple stuff sack. This not only keeps your rope clean and protected but also makes deployment a breeze. Picture this: you're on a boat, and suddenly need to secure a fender. With your neatly stored 1" braided nylon rope, you can quickly grab the exact length you need without any tangles or fuss.

In conclusion, the lightweight and easy handling characteristics of 1" braided nylon rope make it an invaluable tool for a wide range of applications. Whether you're a weekend warrior or a seasoned professional, this versatile rope is sure to become your go-to choice for all your rigging needs. So why not give it a try on your next project? You might just wonder how you ever managed without it!

Versatile Applications of Braided Nylon Rope

As a seasoned rope enthusiast, I've seen braided nylon rope shine in countless scenarios. Its remarkable versatility stems from its unique combination of strength, flexibility, and durability. Let's dive into the myriad ways this wonder-cord proves its worth across various industries and activities.

Industrial and Marine Uses

In the industrial realm, braided nylon rope is a true workhorse. I've witnessed its prowess firsthand during a visit to a bustling shipping yard. The air was thick with the scent of salt and diesel as massive cargo containers swayed gently, secured by robust nylon lines.

- Mooring and anchoring: Ships of all sizes rely on braided nylon rope for secure moorings. Its ability to absorb shock and resist abrasion makes it ideal for withstanding the constant motion of tides and waves.

- Cargo securing: From trucks to container ships, nylon rope keeps loads safe and stable during transit. Its high tensile strength ensures that even the heaviest cargo stays put.

- Safety barriers: In construction sites and industrial facilities, braided nylon rope often serves as a crucial safety measure, creating temporary barriers and guide lines.

Have you ever wondered why nylon rope is so prevalent in these demanding environments? It's not just about strength - it's the rope's resistance to moisture, oil, and chemicals that makes it a top choice for industrial applications.

Outdoor and Recreational Applications

As an avid outdoor enthusiast, I've come to appreciate the versatility of braided nylon rope in my adventures. Whether I'm scaling a cliff face or setting up camp in the wilderness, this trusty cord never lets me down.

In the world of rock climbing and mountaineering, braided nylon rope is quite literally a lifeline. Its excellent shock absorption properties make it ideal for dynamic climbing ropes, while its durability ensures it can withstand the harsh conditions of rugged terrain. Learn more about why braided nylon ropes outperform in our Advantages of Double Braided Nylon Rope for Offroad and Marine article.

For camping and hiking enthusiasts, this versatile rope proves invaluable:

- Tent guy lines: The weather-resistant properties of nylon rope make it perfect for securing tents in all conditions.

- Bear bags: When camping in bear country, nylon rope helps keep food safely out of reach of curious wildlife.

- Emergency repairs: From fixing a broken backpack strap to creating a makeshift clothesline, the uses are endless.

In water sports, braided nylon rope shines as tow ropes for water skiing and wakeboarding. Its ability to float and resist UV damage makes it a favourite among boating enthusiasts.

From the depths of industrial complexes to the heights of mountain peaks, braided nylon rope proves its worth time and time again. Its versatility, coupled with its impressive strength and durability, makes it an indispensable tool across a wide range of applications. Next time you embark on an outdoor adventure or tackle a DIY project, consider the humble braided nylon rope - it might just be the solution you've been looking for.

Explore the Benefits of Braided Nylon Rope

Discover the unparalleled strength, durability, and versatility of braided nylon rope. With a high tensile strength that withstands heavy-duty use, this rope remains resilient even when wet or exposed to UV rays. Its lightweight and easy handling properties make 1 braided nylon rope perfect for both professionals and DIY enthusiasts, offering exceptional portability and manoeuvrability. Ideal for marine, industrial, and outdoor applications, nylon rope braided provides reliable performance across various industries. Fill in the inquiry form above to learn more about how our customised ropes can meet your specific needs and enhance your projects.