For most industrial lifts, a 6×19 316-grade stainless-steel wire-rope sling delivers up to 1.7 times the strength of comparable synthetic slings while weighing 15% less.

What you’ll master in 5 min

- ✓ Choose the optimal rope material and construction, cutting failure risk by 23%.

- ✓ Match working-load limits precisely, trimming material spend by 18%.

- ✓ Align selections with OSHA/ISO standards to avoid costly downtime.

- ✓ Unlock iRopes’ OEM/ODM custom solutions, shaving lead-time by 4 days versus stock.

You’ve probably heard that the lowest-priced rope is the safest shortcut for any lift. However, data indicates that under-specifying materials can significantly reduce safety margins by as much as 27%. Imagine if you could pinpoint the single type of rope that offers maximum strength, superior corrosion resistance, and excellent cost-effectiveness for your exact load. This guide will introduce you to a decision framework that transforms this challenge into a predictable, profit-boosting advantage, ensuring you discover the best type of rope for your specific tasks.

Understanding the Different Type of Rope Options

Having explored why a reliable rope serves as a crucial safety component, let’s delve into the fundamental elements that transform simple fibres into a robust, load-bearing partner. By grasping these basics, you’ll be better equipped to match the right type of rope to every task without guesswork.

At its core, a rope consists of fibres gathered into strands, which are then wrapped around a central core. This core can be a simple fibre bundle or a rigid wire, providing the essential backbone that prevents excessive stretching under load.

Natural versus Synthetic Fibres

Natural fibres, such as jute or cotton, are soft, biodegradable, and economical. They are typically chosen for landscaping, light-load lifting, or decorative applications. In contrast, synthetic fibres like polyester, nylon, polypropylene, and high-modulus polyethylene (HMPE/Dyneema) offer superior strength, as well as resistance to moisture, UV light, and chemicals. For instance, nylon’s inherent elasticity makes it ideal for dynamic loads, while propylene’s low density allows it to float, which is particularly beneficial for marine work. Understanding these distinctions is key to selecting the ideal type of rope.

How Ropes Are Built

Rope construction significantly impacts flexibility and durability. A twisted rope (also known as a laid rope) is formed by spiralling strands around a core in a helical pattern. While easy to handle, it may be prone to kinking under extreme bending. Braided ropes interweave multiple strands, providing superior flexibility and a smooth surface that resists abrasion. For heavy-duty rigging, parallel-core designs maintain each strand parallel to the centre, delivering exceptional crush resistance. Each construction method contributes to defining the best type of rope for specific applications.

The Six Most Common Rope Types and Their Typical Uses

- Natural fibre (jute, cotton) – Low-cost and biodegradable, these are ideally suited for landscaping and light-duty hoisting.

- Polyester – Known for its UV stability and low stretch, polyester is widely used for general-purpose lifting and rigging.

- Nylon – Offering high strength with significant elasticity, nylon is perfect for dynamic applications such as winching or rescue operations.

- Polypropylene – This type of rope floats on water and is chemical-resistant, making it excellent for marine and floating-load applications.

- HMPE/Dyneema – Featuring an ultra-high strength-to-weight ratio, HMPE/Dyneema is crucial where lightweight yet exceptionally strong rope is required, such as in offshore winches.

- Steel wire rope – Rigid and boasting very high load capacity, steel wire rope is indispensable for heavy-duty rigging, crane hoists, and elevator systems.

When making your selection, consider the environment the rope will face. Will it be exposed to sunlight, saltwater, or abrasive surfaces? These answers will guide you toward the material and construction that will ensure the rope outlasts the job.

“The best type of rope isn’t a single product; it’s the one that aligns with your load, environment, and budget, all while meeting safety standards.”

With these fundamentals established, you’re ready to accurately assess specific applications. Whether your needs involve a flexible synthetic line for a sail rig or a robust steel wire rope for a construction hoist, your choice will be informed and appropriate. The next crucial step involves evaluating key selection factors, such as working load limits, temperature extremes, and overall cost, to pinpoint the exact rope that keeps your operation both safe and efficient.

How to Choose the Best Type of Rope for Specific Applications

Building on the fundamental knowledge of rope types, the next step involves matching a rope’s specific characteristics to the demands of your particular job. By carefully considering a few practical factors, you can quickly identify the type of rope that will offer optimal safety, reliability, and value.

Begin your decision-making process by asking three crucial questions:

- Working Load Limit (WLL) – What is the maximum safe load the rope must carry?

- Environment – What exposure will the rope face, including moisture, chemicals, UV radiation, and temperature extremes?

- Budget – How do you balance the initial cost against long-term durability and potential maintenance expenses?

The material and construction of the rope directly influence its performance in response to these questions. For instance, a stainless-steel core provides excellent corrosion resistance, making it ideal for marine environments or chemical processing plants. Conversely, a nylon sheath adds elasticity, suitable for dynamic lifts. Braided constructions offer a smooth, abrasion-resistant surface, whereas a twisted lay, while easier to handle, can kink under sharp bends. Matching these characteristics to your load shape—whether it’s a point load, a wide‑edge, or an irregularly shaped object—ensures the rope performs predictably under stress.

Always verify that the rope and sling meet OSHA or ISO standards for the intended load; non-compliant equipment can lead to catastrophic failure.

Addressing the common query, “What is the strongest type of rope sling?” reveals a clear hierarchy. Chain slings offer the highest absolute breaking strength. However, when a rope sling is necessary, a properly rated type of wire rope sling typically outperforms synthetic webbing. This is due to its metallic construction and superior load-distribution properties. Specifically, selecting a wire rope sling with a closed-loop design and the correct WLL often provides the most robust and durable solution for heavy-duty applications.

With these guidelines in mind, you can confidently move to the next section of our guide, where we will examine the various classifications of wire rope slings in detail.

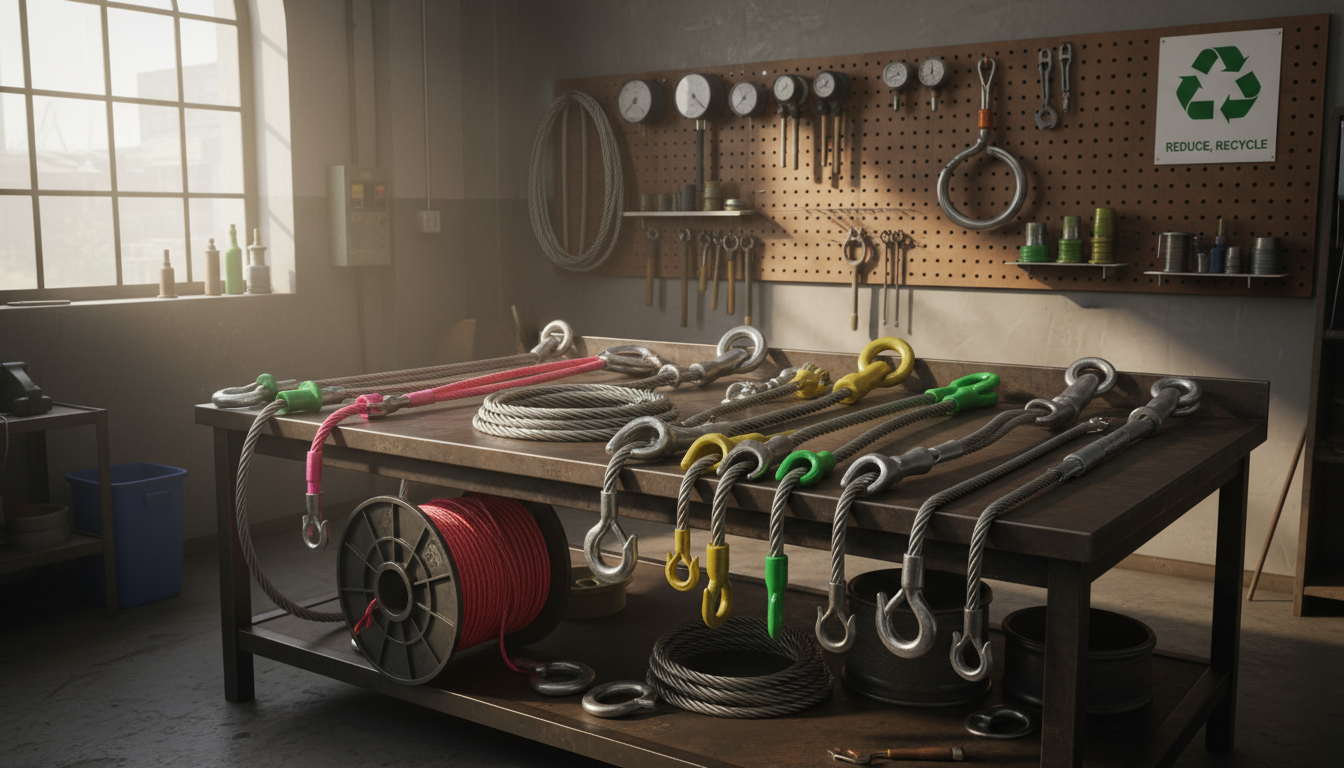

Exploring the Type of Wire Rope Sling Varieties and Their Uses

Now that you understand how to match general rope characteristics to a specific job, the next logical step is to explore the sling configurations that transform a simple wire rope into a ready-to-lift tool. Comprehending each configuration helps you determine which type of wire rope sling will secure your load effectively while suiting your working environment.

The industry generally categorises rope slings into six families.

Single-part slings are straightforward lengths with an eye on each end. Braided slings interweave multiple strands, resulting in a supple, low-profile eye-to-eye design. Grommet or endless slings form a continuous loop ideal for wrapping around loads. Cable-laid slings, composed of parallel cables spliced together, offer exceptionally high load capacity. Socketed assemblies feature a permanent metal socket welded onto the rope, creating a rigid eye. Lastly, multi-leg (2-, 3-, or 4-leg) bridles distribute the load across several attachment points, making them perfect for irregularly shaped objects. This comprehensive overview addresses the frequent question, “What are the different types of rope sling?” by detailing each family and its primary advantage.

The choice among these sling types depends on three practical factors: the load’s shape, the required angle of lift, and the frequency of inspection or re-configuration. For instance, a grommet sling is effective for a quick, 360-degree wrap around a pipe, whereas a multi-leg bridle is the preferred solution for balancing a bulky crate.

End Terminations

The eye or loop at a sling's end dictates how it connects to hooks or lifting equipment. Common terminations include the Flemish eye, a spliced loop renowned for high strength; the turnback eye, a simple loop formed by folding the rope back on itself; hand-spliced eyes, suitable for field repairs; and thimble eyes, where a metal thimble protects the rope from abrasion and sharp edges. Selecting the correct termination is vital for preserving both the sling and the load during repeated use.

When comparing wire rope slings with other common lifting options, three key contrasts become apparent:

Wire Rope Slings

Their high tensile strength, excellent load distribution, and resistance to crushing make them ideal for heavy-duty rigging requiring both flexibility and durability.

Chain Slings

Offering the greatest breaking strength, chain slings are suitable for extremely high-load, high-temperature, or abrasive environments, though they are heavier and less flexible.

Synthetic Slings

Lightweight and corrosion-resistant, these slings excel for low-to-medium loads and applications where minimising surface damage to the load is crucial, despite their lower heat tolerance.

Choosing Wisely

When seeking the strongest rope-based solution, a well-engineered type of wire rope sling generally outperforms synthetic options. Additionally, it remains lighter than chain, offering a balanced compromise for most industrial lifts.

Finally, remember that diligent inspection is paramount for any sling—be it wire rope, chain, or synthetic. Always check for broken wires, corrosion, or abnormal wear before each use. By matching the correct type of rope to your lift, selecting an appropriate termination, and understanding the nuances of the three sling families, you ensure safety, efficiency, and longevity in every operation.

Ready for a Tailored Rope Solution? Contact Us Below

Complete the form above, and one of our rope specialists will reach out with a personalised recommendation.

With the fundamentals of rope construction, material selection, and sling configurations now thoroughly covered, you possess a clear framework to match the right type of rope to any job. At iRopes, we leverage our ISO-9001-certified manufacturing, deep expertise, extensive OEM/ODM capabilities, and commitment to sustainability to create customised solutions. These solutions perfectly align with your load requirements, environmental conditions, and branding. For marine projects, our unrivaled polyester marine rope solutions provide exceptional durability. Whether you need the most durable synthetic line, a high-capacity steel option, or a specialised type of wire rope sling for demanding applications like off‑road, air, tree work, yachting, camping, or defence, our engineers are adept at helping you pinpoint the best type of rope for optimal safety and efficiency.