iRopes delivers marine rope and reel packages engineered for consistent strength under an ISO 9001 quality management system. With 15 years of manufacturing in China and a range of 2,348 cordages across UHMWPE, Technora™, Kevlar™, Vectran™, polyamide and polyester, we provide customised solutions and palletised global shipping.

What you’ll gain – 3 min read

- ✓ Tailored ropes meet the required working load limit, improving safety margins for your vessel and crew.

- ✓ OEM/ODM programs deliver cost‑effective specifications without compromising performance.

- ✓ ISO 9001 quality systems support consistent, low‑defect production and reliable deliveries.

- ✓ Direct‑ship pallets streamline logistics and reduce handling at your facility.

- ✓ End‑to‑end IP protection and branded or plain packaging options to suit your market.

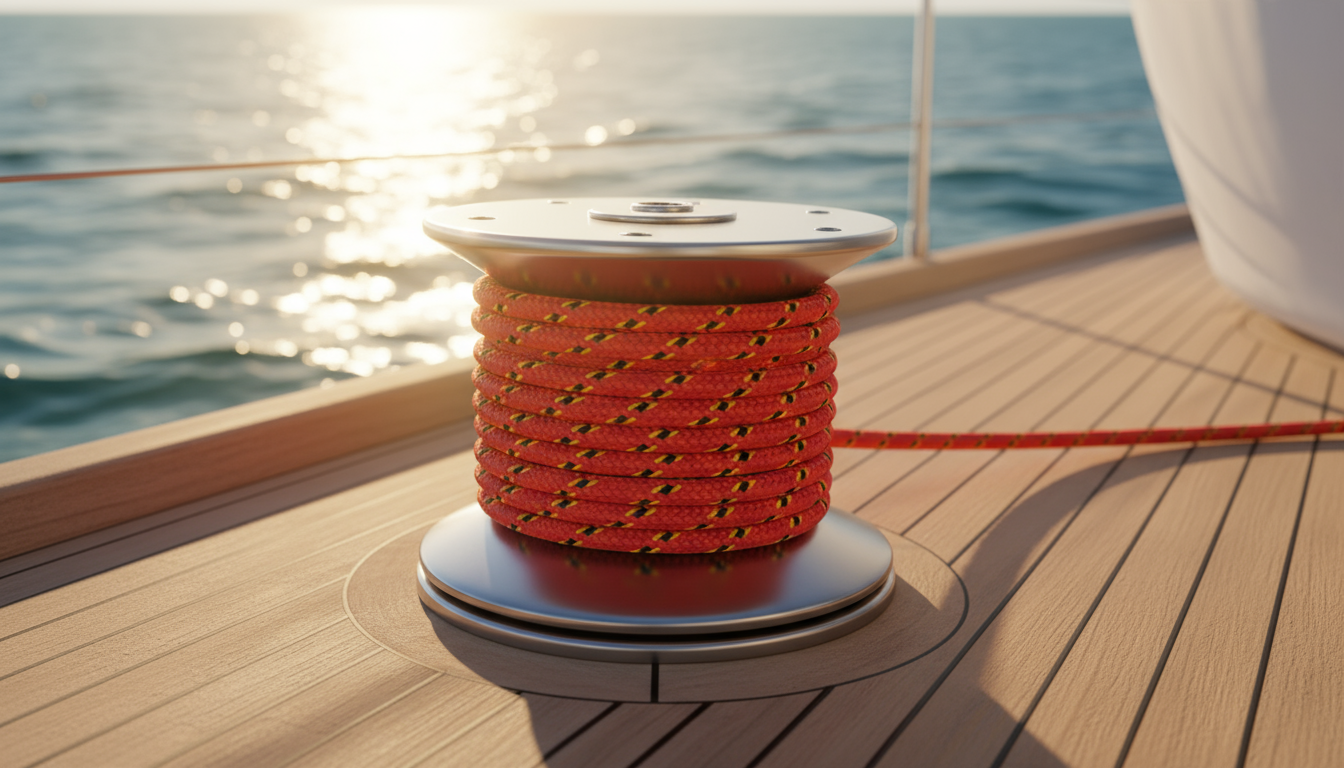

Many operators default to the cheapest off‑the‑shelf gear and hope for the best—until a snapped line causes downtime. From rope reels marine to polyester marine rope and marine polypropylene rope, you can replace that guesswork with a rope‑and‑reel solution engineered to your load profile, reducing failure risk and shortening replacement cycles. In the sections ahead, we share practical design choices and ordering tips to help you specify the right setup with confidence.

Choosing the Right rope reels marine for Your Vessel

When you’re planning a new rig or upgrading an existing deck, the reel you pick can feel as important as the rope itself. A well‑matched reel not only speeds up line handling but also protects the fibre from abrasion and overload. Let’s walk through the choices so you can pick the perfect fit for your boat.

- Reel styles - single‑flange, double‑flange, wooden and aluminium options each suit different deck layouts and load demands.

- Load rating basics - reels are rated by working load limit; iRopes manufactures and inspects under an ISO 9001 quality system for consistent, traceable quality.

- Mounting & installation - deck‑mounted systems can be bolted, welded or fitted with vibration‑isolating pads; a 300‑ft line typically needs a flange ≥ 1.5 × rope diameter, and plan reel width using an ≈ 30:1 length‑to‑diameter ratio.

Choosing the right size also answers a common question: What size reel do I need for a 300‑ft rope? The rule of thumb is that the reel’s flange diameter should be at least one and a half times the rope’s diameter to avoid excessive bending stress. In addition, ensure the reel’s width can accommodate the rope length, and verify the reel’s rating meets or exceeds the rope’s working load limit.

Our 15‑year OEM/ODM track record means every rope and accessory we supply is built to your specifications and documented under ISO 9001.

Because the reel and rope must work together, the next step is to match the reel to the fibre you’ll be using. Polyester marine rope, for example, benefits from a sturdy aluminium reel that resists corrosion while providing the stiffness needed for anchoring lines. With iRopes’ custom‑design capabilities, you can specify colour, branding and even specialised coatings to keep the reel‑rope combo performing season after season.

Why polyester marine rope remains the workhorse of offshore rigging

After learning how the right reel protects a line, the next decision is the fibre that actually bears the load. Polyester marine rope has earned its reputation because it balances durability with predictable performance, even when the sea throws its harshest conditions at you.

The material’s core attributes explain why it dominates offshore applications. First, its UV‑stabilised coating helps shield the fibres from sun‑induced degradation, so colour fade and strength loss stay minimal after exposure. Second, the low‑stretch nature means a line holds tension without spring‑back, which translates into steadier anchoring and smoother handling on winches. Third, polyester’s density (about 1.38 g/cc) ensures the rope sinks, keeping it out of the way of floating debris and preventing entanglement in safety nets. Finally, its tensile strength—often exceeding 7,000 lb for common diameters—provides a generous margin when you apply the standard factor‑of‑five safety rule.

- UV resistance – protects fibre integrity under prolonged sunlight.

- Low stretch – maintains consistent load without excessive elongation.

- Sinking behaviour – stays beneath the water surface, reducing snag risk.

Because of these traits, polyester is the go‑to choice for dock lines that must resist constant abrasion, anchoring rigs that rely on steady pull, and permanent mooring setups where a sunk line is safer than a floating one. If you need a rope that will not balloon in the sun or stretch when you’re trying to set a tight berth, this fibre delivers exactly that. For detailed specifications, see our polyester rope strength chart.

Custom Options

iRopes can tailor polyester rope to your brand and performance needs: choose any diameter from 1/4″ to 1¼″, pick colour codes that match your hull, add your logo to the sheath, or request specialised coatings such as extra‑hard UV inhibitors for tropical deployments.

When you wonder how polyester differs from its lighter cousin, the answer lies in both physics and use‑case. Polyester sinks and offers superior UV protection, while marine polypropylene rope is lighter, floats, and tolerates chemicals but stretches more and loses strength faster under sunlight. Choosing between them hinges on whether you need a line that stays submerged and holds tension (polyester) or one that must remain on the surface for safety‑net or buoy‑line applications (polypropylene).

With the fibre’s characteristics clarified, the next part of the guide will explore when the floating nature of marine polypropylene rope makes it the optimal solution for buoy lines, safety nets, and other specialised tasks.

When marine polypropylene rope is the optimal choice for floating lines

After exploring polyester’s strengths, let’s turn our attention to the material that literally stays on top of the water. Marine polypropylene rope’s buoyant nature makes it the go‑to solution for safety‑net lines, buoy lines and any application where visibility and floatability are non‑negotiable.

Because polypropylene’s density is around 0.91 g/cc, the line floats rather than sinks. This property answers a frequent query: Do marine ropes float or sink? The answer is simple – polypropylene floats, while polyester sinks. The floatability also means that a broken line remains on the surface, easy to retrieve, and it never disappears beneath a vessel’s hull. Learn about popular applications in water sports in our top water sports uses for polypropylene cord guide.

Floatability

Polypropylene’s low density keeps the line on the surface, ensuring that safety‑net and buoy lines remain visible.

Chemical resistance

The fibre repels oil, salt and many marine chemicals, so performance stays consistent even in polluted harbours.

Sizing

Pick a diameter whose working load limit (WLL) exceeds the maximum tension; for example, a 3/8″ three‑strand line often has a WLL around 480–500 lb, depending on construction.

Maintenance

Rinse with fresh water after each use, store out of direct sunlight, and retire lines that show heavy abrasion or UV damage.

When you calculate the required size, start with the maximum expected load and multiply by a safety factor of five, as commonly recommended by the US Coast Guard. That gives you the required minimum breaking load (MBL). Then select the smallest diameter whose MBL meets or exceeds that number. For example, a ½″ polypropylene line typically has an MBL of about 3,800 lb, giving a WLL of roughly 760 lb.

Safety tip: Inspect lines every six months; replace if you see abrasion, UV‑cracking, or other signs of strength loss. For high‑usage dock lines, plan proactive replacement every 2–3 years.

Maintenance isn’t just about cleaning; it’s also about tracking the rope’s age. Polypropylene degrades faster under UV exposure, so even a chemically‑resistant line should be stored in a shaded rack when not in use. Re‑spooling onto a clean reel every season prevents uneven wear and extends service life.

iRopes’ OEM expertise means you can order marine polypropylene rope in colours that match your fleet’s branding, and have your logo printed on the sheath or added as woven tracers. Custom‑colour runs not only improve visual identification on busy decks but also reinforce safety protocols by making the floating line unmistakable.

Choosing the right floating line and pairing it with a compatible rope reel ensures that your safety‑net, buoy or rescue system works reliably whenever the sea demands it, setting the stage for a seamless transition to the final wrap‑up of this guide.

Need a custom marine rope solution?

By now you understand that selecting the right rope reels marine and pairing them with the appropriate fibre is crucial for safety and performance. Whether you need the low‑stretch, sinking reliability of polyester marine rope for anchoring, or the buoyant, chemical‑resistant advantages of marine polypropylene rope for safety‑net lines, iRopes’ 15‑year Chinese manufacturing pedigree and ISO 9001‑backed quality ensure a precise fit. Our OEM/ODM capabilities let you customise diameter, colour, logo and special coatings across advanced fibres—from UHMWPE and Technora™ to Kevlar™, Vectran™, polyamide and polyester—delivering a solution that matches your vessel’s exact demands. We also safeguard your IP, offer non‑branded or customer‑branded packaging, and ship palletised orders worldwide. Need help tailoring a boat rope reel? Check out our guide on customizing your 2‑inch boat rope reel.

If you’d like a personalised quote or technical spec sheet, simply complete the form above and a dedicated iRopes specialist will work with you to fine‑tune every detail.