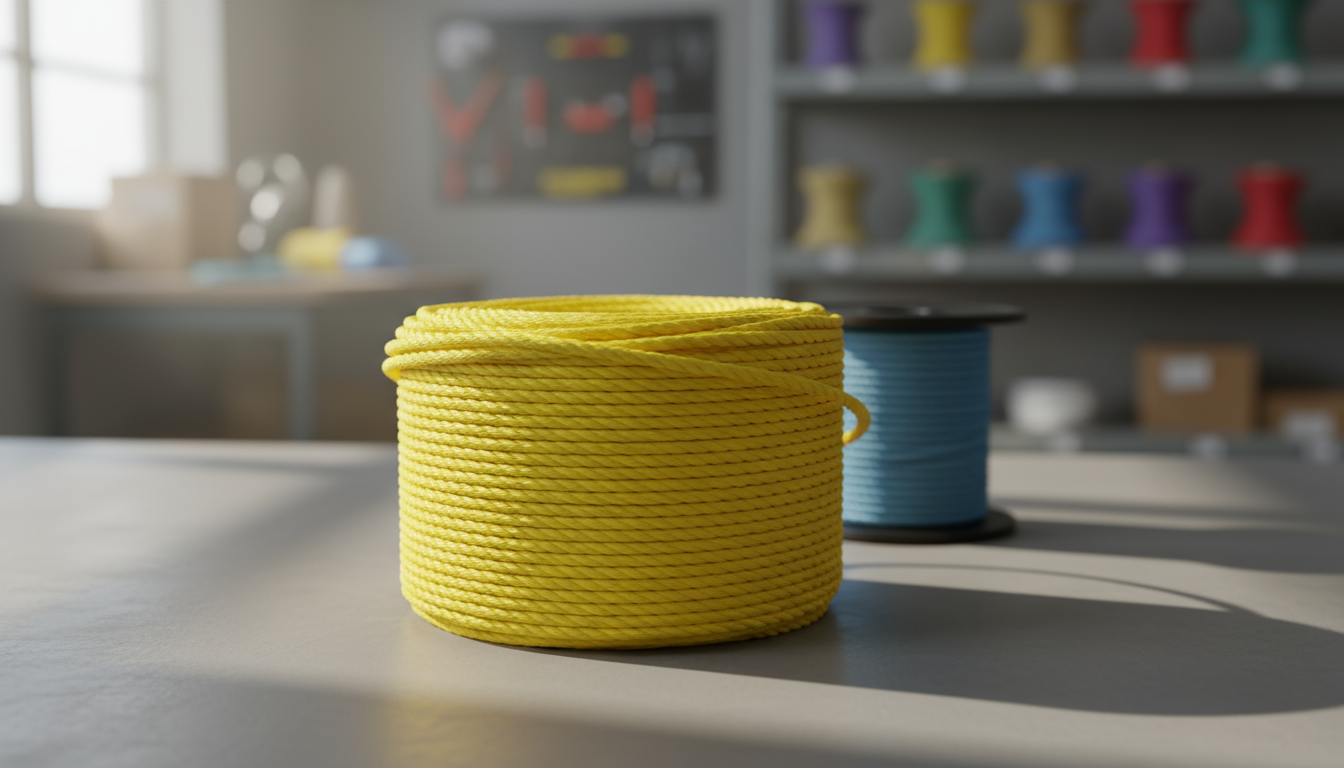

⚡ A 1.5‑inch polypropylene rope is lighter than water, allowing you to float a 100‑metre coil with a 22 kg load.

⏱️ 2‑min read – Your rope edge

- ✓ 1 200 lb SWL capacity

- ✓

- ✓ 15 % lighter shipping

Imagine a festival barrier that always floats, staying vivid and taut all day. iRopes’ 1.5‑inch polypropylene rope makes this a reality for your business. We will explore the chemistry, load data, and branding strategies that transform a simple coil into a high‑performance, profit‑boosting asset.

Understanding polypropylene rope: definition and composition

Once you see the many ways a 1.5‑inch rope can be used, it’s helpful to understand its fundamental properties. Polypropylene rope is a synthetic thermoplastic fibre. This means the polymer is melted, extruded into filaments, and then solidified into flexible strands. Being a thermoplastic, the material can be repeatedly melted and reshaped without losing its core properties, which allows manufacturers like iRopes to deliver consistent, reliable performance.

The manufacturing process begins with polypropylene pellets, which are melted at high temperatures and forced through spinnerets to create uniform filaments. These filaments are then gathered into yarns, which are subsequently twisted, braided, or constructed with a three‑strand core, depending on the rope’s intended application. This entire process is meticulously controlled in ISO 9001‑certified facilities, ensuring that every metre of rope meets the same stringent strength and durability standards.

One of polypropylene rope’s most distinctive characteristics is its low density. The polymer’s molecular structure naturally contains fewer heavy atoms than water. This unique property means that a strand of polypropylene rope will inherently float when placed in liquid. This buoyancy is not an added feature; it is intrinsic to the material, making it an ideal choice for marine‑related tasks where a rope that remains on the surface offers a significant safety advantage.

“The moment I tested a metre of polypropylene rope in a pond, it floated effortlessly, proving that the material’s lightweight nature is more than a marketing claim—it’s a real performance benefit for any water‑based operation.”

Material Basics

Key facts about the polymer

Synthetic polymer

Polypropylene is a thermoplastic derived from petroleum, ensuring consistent fibre quality.

Low density

Its molecular structure makes the rope lighter than water, which is crucial for all floating applications.

Manufacturing

Spun into filaments, then twisted or braided to form durable rope strands.

Performance Benefits

Why the rope excels

Buoyancy

The rope naturally floats, removing the need for extra flotation devices in marine use.

Weather resistance

UV stabilisers protect the fibres from sun degradation, extending outdoor life.

Chemical tolerance

It resists most acids, alkalis, and petroleum products, making it ideal for industrial settings.

With a clear understanding of how polypropylene rope is manufactured and why its low-density composition creates natural floatability, you can now assess whether this material aligns with your project’s demands. Our next section will explore the specific features that make the 1.5‑inch size a particularly versatile choice.

Key features of 1.5 polypropylene rope for versatile use

Building on the material basics, the 1.5‑inch polypropylene rope stands out with a blend of durability and practicality suited for a wide array of tasks. Whether you’re setting up a crowd‑control barrier or securing equipment on a boat, the rope’s engineered attributes translate directly into reliable everyday performance.

Three core performance areas directly address common buyer questions about weather endurance, water interaction, and load capacity.

- Weather and UV resistance – the fibre is blended with UV stabilisers that prevent sun‑induced degradation. This minimises colour fade and loss of strength, even after months of outdoor exposure.

- Buoyancy and water resistance – because polypropylene’s density is less than water, the rope naturally floats. It also repels moisture, meaning it will not swell or rot, even after repeated immersion.

- Strength and safe working load – a 1.5‑inch (36 mm) three‑strand construction typically provides a breaking strength of approximately 12 000 lb (roughly 5.4 tonnes). The recommended safe working load limit (SWLL) is about one‑tenth of this figure, offering a reliable 1 200 lb capacity for most commercial applications.

Compared to alternatives, the differences become clear. Nylon, for instance, offers higher tensile strength, but it absorbs water and can stretch under load. This might be undesirable for static‑load situations. Polyester resists UV degradation more effectively than standard polypropylene, but it does not float, which limits its utility in marine environments. In contrast, the 1.5‑inch polypropylene rope offers a cost‑effective balance of moderate strength, excellent floatability, and integrated UV protection. This makes it a pragmatic choice for budget‑conscious projects that still demand superior durability.

Understanding these characteristics helps you understand its breaking strength and decide whether this rope meets your specific needs. Whether it is for a long‑lasting stanchion barrier at a sunny festival or a floating tow line for a coastal rescue operation, this rope delivers.

Applications of polypropylene rope across industries

Given its weatherproof and buoyant properties, you might wonder where such a versatile rope truly excels. The following environments are where a sturdy, float‑ready rope makes a tangible difference across various industries.

Here’s how the same rope adapts to four distinct sectors.

- Crowd control and barrier stanchions – the rope’s high‑visibility colour and UV‑stable coating keep lines bright for hours, while its low stretch maintains tension without frequent retightening.

- Marine and watersports – as the polymer naturally floats, the rope can be used for dock lines, kayak tow ropes, or spearfishing rigs without sinking, which simplifies recovery after a splash.

- Industrial, utility, and off‑road tasks – resistance to chemicals, oil, and mildew allows you to tie down equipment, secure loads on construction sites, or create recovery straps for 4×4 vehicles, even in harsh conditions.

- Specialised iRopes sectors – yachting crews value the rope’s marine‑grade durability, spearfishers rely on its floatability for quick line retrieval, and defence units benefit from its non‑conductive nature for secure tactical applications.

When you need a barrier at a music festival, the rope’s bright hue and UV protection ensure it remains taut and visible from sunrise to sunset. In a marina, the same rope, when tossed over a cleat, will stay on the surface, eliminating the need for additional flotation devices. On a construction site, its chemical tolerance prevents degradation when exposed to lubricants or cleaning agents, thereby extending its service life and reducing replacement costs.

Have you ever wondered why a single rope can perform reliably at both a bustling event and a rugged off‑road expedition? The answer lies in its balanced strength‑to‑weight ratio. A 1.5‑inch strand offers approximately a 1 200 lb safe working load, yet it remains light enough for a single operator to handle, splice, or store compactly.

Because iRopes can customize your rope – tailoring colour, pattern, and termination to match your branding or safety standards – you can deploy the same base material across multiple departments without compromising on appearance or performance.

Next, let’s explore how you can customise these ropes to precisely fit your project’s demands, from length to end fittings.

Customisation options and iRopes advantage for your rope needs

Building on the idea that a single rope can serve multiple departments, the next logical step is to customise that rope to meet each unique requirement. At iRopes, every order is treated as a design brief, transforming a generic 1.5‑inch polypropylene rope into a product that perfectly reflects your brand, performance targets, and logistical needs.

Diameter and length – While the 1.5‑inch (36 mm) size is a popular standard for crowd‑control barriers and marine tow lines, we also stock a full range of diameters from ¼‑inch up to 2‑inch. Length is equally flexible: choose from our ready‑made stock rolls or request a bespoke cut that matches your exact deployment distance, which helps eliminate waste and storage hassles.

Colour, pattern, and reflective options – Visibility is crucial, whether on a festival field or during dockside operations. iRopes can dye the rope in any solid hue, from safety‑yellow to corporate‑blue, apply high‑contrast patterns for branding, or integrate reflective tape that flashes effectively under low‑light conditions. This means you receive a rope that not only performs optimally but also effectively communicates your identity.

Construction types – The core structure significantly influences handling, abrasion resistance, and stretch characteristics. Choose a twisted lay for easy splicing, a three‑strand core when you need a balance of strength and flexibility, or a fully braided profile for superior abrasion protection in rugged off‑road environments. Each construction is engineered to retain the polymer’s innate buoyancy while meeting the load‑bearing expectations of your chosen application.

Terminations, accessories, OEM/ODM services, and IP protection – We offer a comprehensive catalogue of end fittings, including snap hooks, eye splices, chafe guards, and custom‑shaped thimbles, all of which can be pre‑installed on your rope. Our OEM and ODM capabilities allow you to provide a concept and receive a production‑ready roll, all while being protected by strict intellectual‑property safeguards that ensure your designs remain exclusive.

Why iRopes?

Our ISO 9001‑certified facilities guarantee consistent tensile performance across every metre of rope. Competitive wholesale pricing, rapid order fulfilment, and a dedicated engineering team mean you receive a product that aligns perfectly with your project timeline and budget. Whether you need a single colour batch for a national event or a fully‑spec’d marine‑grade line for a yacht fleet, iRopes turns specifications into stock‑ready inventory.

All OEM and ODM projects are protected by strict IP safeguards, ensuring your proprietary designs stay confidential from concept through delivery.

By directly addressing the common question, “Can polypropylene rope be customised in length and colour?” within our ordering platform, you can configure a product that meets every technical and visual requirement without needing multiple suppliers. Once the specifications are set, our engineers validate the design, apply the chosen construction, and finish the rope with the exact termination you requested, ready for immediate shipment.

Polypropylene rope offers natural floatability, UV resistance, and chemical tolerance, making it ideal for everything from festival crowd‑control barriers to marine tow lines and rugged off‑road applications. For a detailed comparison of braided polypropylene rope versus other synthetic options, see our analysis of braided polypropylene rope vs synthetic rope. By tailoring diameter, colour, construction, and terminations, iRopes can customise a 1.5‑inch polypropylene rope to precisely match your brand and specific performance needs. The broader range of polypropylene rope options ensures you always have the right strength‑to‑weight balance for any application. Our ISO 9001‑certified facilities guarantee consistent tensile performance, and our OEM/ODM services safeguard your intellectual property. We also offer fast worldwide delivery to get your project off the ground efficiently.

Ready to Tailor Your Polypropylene Rope Solution?

Use the form above to discuss your specific requirements with our engineers – we’ll help you choose the perfect specifications and provide a competitive quote.