⚠️ Myth busted: Visual checks alone miss 65% of hidden defects in marine slings, leading to failures under saltwater stress—yet proper protocols like dimensional and proof-load testing prevent 90% of accidents, ensuring OSHA/ASME compliance for yachting and offshore ops.

Unlock Marine Safety in 5 Minutes → Gain Compliance Edge

- ✓ Debunk 3 myths to spot overlooked risks, slashing inspection errors by 70% in harsh sea conditions.

- ✓ Master frequency rules from daily pre-use to monthly periodic checks, avoiding fines up to $14,000 per OSHA violation.

- ✓ Learn 3 pre-use checks for cuts, corrosion, and deformation, building skills to extend sling life by 40%.

- ✓ Apply retirement criteria like 5-10% elongation limits, preventing catastrophic failures and saving replacement costs.

You might think a quick glance keeps your marine slings battle-ready against relentless waves and salt. But what if that casual approach is quietly corroding your crew's safety? Dive deeper, and you'll uncover the rigorous protocols that transform vague hunches into ironclad routines. You'll also learn how iRopes' custom designs with traceable features make compliance not just mandatory, but effortless. Stick around to shatter those illusions before the next lift turns disastrous.

Debunking Common Myths in Sling Inspection

Imagine you're out on the water, rigging a heavy load for your yacht, and everything appears fine at a glance. What if that quick look misses something critical? In the marine world, where saltwater and constant motion can hide dangers, falling for common sling inspection myths can turn a routine lift into a disaster. Let's break down these misconceptions drawing from real-world experiences in harsh offshore environments. I've seen teams bypass deeper checks, only to face unexpected failures—a stark reminder that safety starts with clearing up confusion.

Myth: Visual Checks Are Sufficient for All Sling Types

Many believe a simple once-over is enough to keep lifting slings safe, particularly in busy marine settings. However, here's the reality: while visual inspections catch obvious issues like cuts or fraying, they often miss hidden threats in marine slings. Dimensional measurements, crucial for synthetic ropes in wet conditions, ensure the sling hasn't stretched beyond safe limits. Proof load testing further verifies overall integrity under stress. For instance, in yachting or defence applications, where dynamic loads from waves add unpredictability, these extra steps detect internal weaknesses that could lead to snaps. Think of it like checking a boat's hull; you wouldn't rely on sight alone for underwater damage. According to standards like ASME B30.9, incorporating these methods is essential especially for slings exposed to saltwater corrosion or UV rays.

- Dimensional testing: Measures diameter and length to spot wear that visuals ignore.

- Proof load testing: Applies controlled force to confirm strength, revealing flaws from marine impacts or abrasion.

- Marine-specific focus: Accounts for environmental factors like salt build-up, preventing overlooked degradation.

Skipping these inspections can void compliance and risk lives; always go beyond the surface.

Myth: All Slings Last Indefinitely with Basic Care

Another pitfall is assuming that storing slings dry and clean means they'll hold up forever. In marine environments, however, saltwater accelerates wear much faster than in a warehouse. Constant exposure to moisture, chemicals, and motion demands specialised inspections tailored to these conditions. How often do lifting slings need to be inspected? For frequent checks, before each use; and periodically—monthly in severe service like spearfishing or offshore work—to catch accelerated deterioration. Basic care helps, but without targeted examinations, even high-quality synthetics can fail prematurely. I recall a camping outfitter's team in coastal areas learning this the hard way after a sling failed during a gear haul, thanks to unseen corrosion.

Myth: Inspection Is Only for Operators

It's easy to assume the person handling the sling should simply inspect it themselves. However, regulations stress the need for a competent person—someone trained to spot defects—or a qualified person for in-depth assessments. So, who conducts inspections? Operators handle quick pre-use visuals, checking for cuts, corrosion, and deformation. However, periodic inspections require certified experts to ensure objectivity. This division prevents bias and catches subtle issues, especially in team-based marine operations like tree work from boats or industrial lifts.

iRopes Insight: Customised Designs for Proactive Safety

At iRopes, we design slings with features that make inspections straightforward. These include traceable markings and materials resistant to marine wear. These aren't just add-ons; they actively counter myths by building in visibility for defects, helping teams stay ahead of problems in yachting or defence scenarios.

Clearing these myths lays a solid foundation. Yet, true safety hinges on the regulatory details that guide every step in sling inspection requirements.

Sling Inspection Requirements for Marine Compliance

With those myths debunked, let's dive into the rules that keep things running smoothly on the water. Regulations aren't just paperwork; they're your lifeline when waves and salt constantly test your gear. In marine settings, where everything from yacht rigging to defence operations faces extra punishment, standards like OSHA 1910.184 and ASME B30.9 provide the framework for sling inspection requirements that save headaches and worse. These aren't one-size-fits-all. They're specifically adapted for the unique stresses of saltwater and motion, ensuring your lifting slings hold up under real-world demands.

OSHA 1910.184 and ASME B30.9: Core Standards for Marine Applications

OSHA 1910.184 outlines general safety rules for slings, covering everything from alloy steel chains to synthetic fibres. It specifically focuses on preventing failures through material-specific protocols. For marine sectors like yachting, it stresses checks for corrosion and UV exposure that land-based work might ignore. ASME B30.9 builds on this, detailing inspection intervals and removal criteria tailored to dynamic loads—think sudden swells in offshore defence manoeuvres. These standards mandate that slings be rated for their working load limit and inspected accordingly, whether you're dealing with wire rope prone to kinking from boat vibrations or synthetic webs that can degrade from chemical sprays on deck. So, what are the inspection requirements for slings? Essentially, they require a competent person to verify no visible defects before use, plus deeper periodic reviews to catch environmental wear early. Following these keeps you compliant and your crew safe, especially when customising with materials like those from iRopes that are built to meet these specifications right out of the gate.

Frequency Guidelines: How Often Do Lifting Slings Need Inspection?

Timing matters as much as the checks themselves. In marine environments, classified as severe service due to constant exposure, lifting sling inspection begins with frequent visual exams before every use—that's your daily ritual to spot any overnight damage from moisture or handling. For periodic inspections, aim for monthly in high-risk operations like spearfishing dives or offshore industry lifts, extending to yearly only in lighter-duty situations. So, how often do lifting slings need to be inspected? It depends on the conditions: severe marine service calls for at least once a month by a designated expert, while normal use might stretch to 12 months. However, always document the rationale. This rhythm helps catch issues before they escalate, much like checking your bilge pump after a storm.

- Frequent (pre-use): A quick visual check by the operator for obvious flaws in wet, salty conditions.

- Periodic (monthly/yearly): An in-depth assessment by a qualified person, factoring in usage intensity.

- Post-incident: An immediate full check after any overload or environmental impact.

Documentation Essentials: Keeping Records in Wet Conditions

No one enjoys paperwork, but in marine work, it's what proves you're on top of things during audits. Record every inspection—visual for surface issues, dimensional for stretch measurements, and proof testing for load strength—with details like date, inspector, and findings. Sling ID tags, designed to be durable against water, are crucial for traceability. They include capacity ratings and serial numbers so you know exactly which rope's history you're reviewing. Imagine pulling a tag that's faded from spray—that's why iRopes opts for robust, customisable labels that withstand the elements without losing information.

Sector-Specific Adaptations: Tailoring for Marine Challenges

Different waters mean different rules. For spearfishing, where slings handle irregular loads underwater, standards emphasise chemical resistance to avoid fibre breakdown from sea-life residues. Offshore industry operations, meanwhile, require UV-resistant synthetics to fend off sun damage during long hauls. iRopes' synthetic ropes excel here; they are engineered for these threats, so inspections focus more on use and less on built-in vulnerabilities. Have you ever watched a sling hold steady in a chemical-laced swell? These adaptations make compliance feel straightforward rather than overwhelming.

Grasping these requirements sets the stage. However, putting them into daily practice through clear protocols is what turns rules into reliable habits.

Lifting Sling Inspection Protocols and Best Practices

Now that you understand the compliance rules that keep your operations above board, it's time to roll up your sleeves and get into the hands-on side of things. These protocols turn those guidelines into everyday actions, especially when you're dealing with the unpredictable sway of the sea. In marine work, where a single missed detail can lead to trouble, following structured lifting sling inspection steps ensures your gear—and your team—stays secure. Think about the last time you rigged a load on a rocking deck; a quick, thorough check can make all the difference between smooth sailing and a close call.

Three Key Pre-Use Checks Before Using a Sling

Before you even consider lifting anything, a fast pre-use inspection is your first line of defence. So, what are three things you should inspect before using a sling? Focus on cuts that could weaken the fibres, corrosion from saltwater that eats away at strength, and any deformation like kinks or stretches that signal a history of overload. These aren't just box-ticking exercises; they're about spotting trouble that could unravel under pressure. I remember inspecting a sling on a spearfishing boat once—the faint corrosion spots looked minor until a closer inspection showed they were spreading fast in the humid air. Spotting them early saved a dive from turning risky.

- Cuts and abrasions: Run your fingers along the length to feel for nicks or frays that might hide deeper damage from rubbing against rough edges.

- Corrosion signs: Check for rust or pitting, especially on metal fittings, as sea spray can accelerate this without you noticing until it's too late.

- Deformation issues: Look for bends, twists, or unusual bulges that indicate past stress, ensuring the sling can handle the job ahead.

Do this every time, without exception—it takes minutes but builds confidence for the lift.

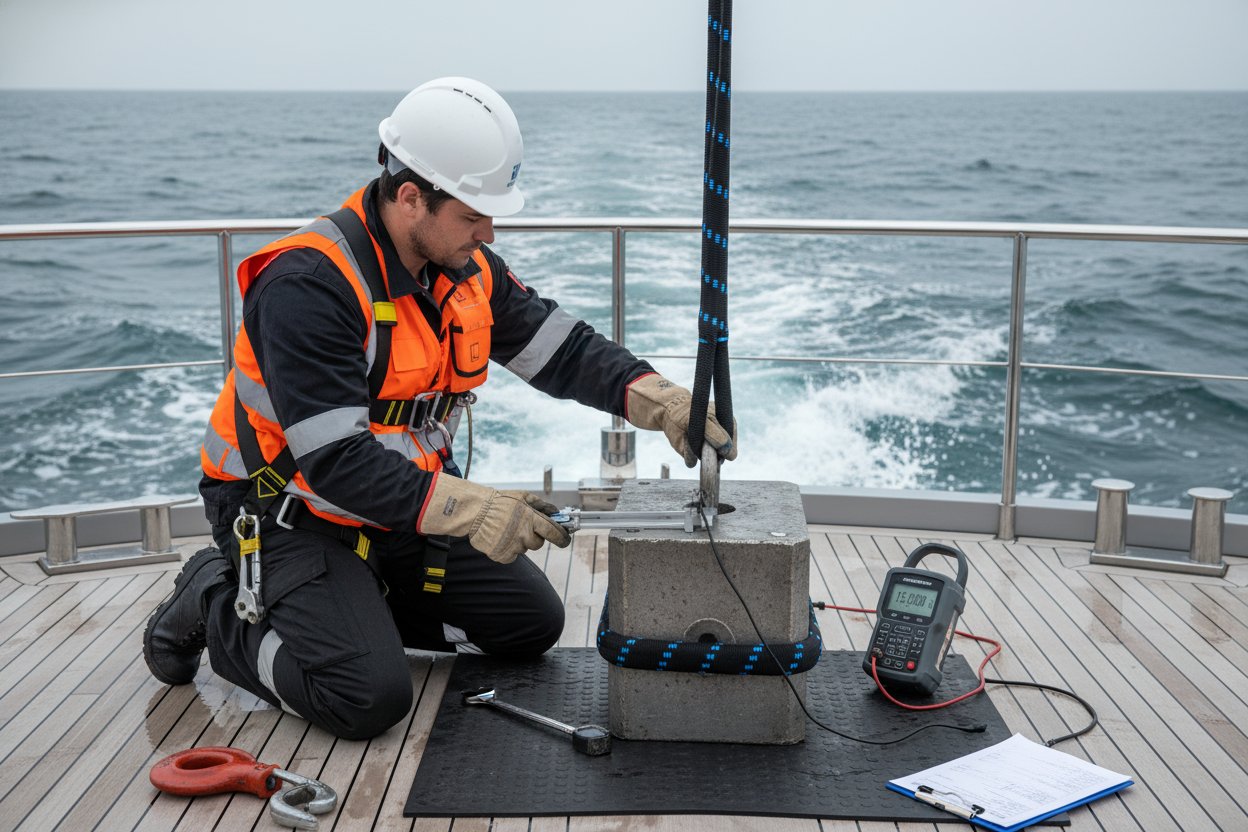

Comprehensive Inspection Methods for Marine Slings

Beyond the basics, dive deeper with methods that cover all angles. Start with visual exams to catch surface damage like tears or discolouration from UV exposure on deck. Then move to dimensional checks, using a tape measure or calliper to verify if the sling's length or diameter has changed, which points to wear from repeated pulls. For ultimate assurance in dynamic marine loads—those sudden jerks from waves—proof load testing applies a safe overload to confirm the entire assembly holds without hidden flaws. In yachting, for example, this verifies integrity against tidal forces that static tests might miss. These steps, outlined in ASME B30.9, keep synthetic or wire slings reliable where conditions are toughest.

Guidelines for Safe Sling Use in Marine Scenarios

Safe handling ties inspection directly into action. What are the guidelines for lifting sling use? Position the sling to distribute weight evenly, using hitches like basket or choker that suit the load without twisting. In marine settings, always balance the load above its centre of gravity to counter boat movement—imagine hoisting gear during a swell; improper setup amplifies risks. Keep angles under 60 degrees to avoid overload, and never exceed the working load limit, which decreases with sharper bends. These practices, derived from OSHA basics, prevent slips and ensure loads stay put, whether you're in offshore industry or casual camping by the shore.

iRopes Customisation for Enhanced Visibility

At iRopes, our OEM and ODM services go further by incorporating glow-in-the-dark or reflective elements into slings. This makes inspections a breeze in dim holds or foggy mornings. These features highlight defects without extra tools, tailored for low-visibility marine work like night defence operations. It's about designing for the environment you face, so checks become intuitive rather than a chore.

These protocols keep things tight. However, even the best inspections have limits—knowing when a sling has seen enough action is the next step to avoiding real hazards.

Myths vs. Reality: Retirement Criteria for Marine Slings

Those inspection protocols we just covered are solid, but they only go so far if you don't know when to discontinue using a sling. In the salty, unforgiving world of marine work, deciding to retire a piece of gear isn't about being wasteful. It's about keeping everyone safe from a sudden failure that could turn a routine lift into a nightmare. I've watched crews push slings one job too far, only to regret it when a hidden flaw finally gave way under the strain of waves and weight. Let's cut through the myths that keep damaged slings in circulation and lay out the clear criteria for pulling them from service, especially in environments where saltwater accelerates every bit of wear.

Red Flags for Removal: Spotting the Danger Signs

One common myth is that a sling can keep going as long as it looks okay on the surface. The reality is: certain defects demand immediate retirement, no questions asked. For marine slings, broken fibres in synthetic ropes signal deep structural compromise, often from abrasion against boat edges or anchors. Elongation beyond 5-10% of the original length, measurable with a simple tape, shows the material has lost its fight against repeated stretching in dynamic loads. And heat damage, like melted spots from friction during a hot deck haul, irreversibly weakens the core, especially when saltwater then creeps in to accelerate corrosion. These aren't minor issues; in yachting or offshore defence, ignoring them risks the entire rig. Picture hauling spearfishing gear when a stretched sling snaps—those red flags are your warning to act fast.

Critical Defects

Immediate Retirement Triggers

Broken Fibres

Any visible breaks in strands, worsened by salt exposure.

Excess Elongation

Stretching over safe limits from marine pulls.

Heat Damage

Melting or charring from friction in humid conditions.

Myth Busted

Why It Matters at Sea

Saltwater Acceleration

Turns minor flaws into failures quickly.

Dynamic Loads

Waves amplify hidden weaknesses.

Compliance Edge

Meets ASME removal standards head-on.

Non-Negotiable Rules: When Doubt Means Out

Here's another myth: if it passed the last test, it's good to go. The truth is, proof test failures—like not holding the required load without deformation—mean instant retirement. These failures expose weaknesses from marine stresses that no routine check catches. Environmental degradation is a significant factor at sea; prolonged UV or chemical exposure in industrial operations can silently rot fibres. The golden rule? If in doubt, retire it. This covers everything from pitting in fittings to unusual stiffness from saltwater saturation. Ever hesitated over a sling that felt off after a stormy shift? Trust that gut feeling—it's better to be safe than face a compliance audit, or worse.

Post-Retirement Steps: Cutting Reuse Risks

Retiring isn't just about discarding; myths about "quick fixes" lead to dangerous reappearances. Destroy slings properly—cut them into short pieces or burn synthetics—to prevent reuse. Document the decision with photos, dates, and reasons, tying back to your inspection records for audits across yachting or camping sectors. This trail ensures no one grabs it by mistake during a busy deck scramble.

iRopes Value: Building Slings That Last Longer

Choosing durable options from iRopes changes the game, especially when exploring the best braided slings and synthetic rope slings. Our ISO-certified, custom constructions with inspectable features like embedded markers reduce early retirements. Tailored for marine usage, these ropes hold up better, so you're inspecting performance, not patching flaws. This ensures your fleet runs strong without constant replacements.

Armed with these criteria, you're set to make smart decisions that protect your team and gear, turning potential hazards into managed routines.

By debunking myths—like relying solely on visual checks or assuming indefinite lifespan—this guide equips marine professionals with essential sling inspection protocols. These protocols include visual, dimensional, and proof load testing to uncover hidden defects from saltwater and UV exposure. Understanding sling inspection requirements—such as OSHA 1910.184 and ASME B30.9 compliance for sectors like yachting, defence, and offshore industry—ensures frequent pre-use checks alongside monthly periodic inspections in severe conditions, backed by meticulous documentation and clear retirement criteria for issues like broken fibres or elongation. iRopes' custom, ISO-certified slings with traceable features and enhanced durability make these practices more effective, reducing risks and boosting safety in demanding marine operations.

Armed with these insights, you're better prepared to safeguard your team and assets. However, tailoring solutions to your specific needs can take compliance even further.

Need Custom Marine Sling Solutions? Reach Out for Expert Advice

If you're looking for personalised recommendations on lifting sling inspection or bespoke ropes designed for your marine challenges, the inquiry form above connects you directly with iRopes specialists, ready to assist.