In the ever-evolving world of ropes, one eternal debate rages on: steel cable rope vs. synthetic rope – which is better? For decades, steel cables have reigned supreme, their rugged construction and unparalleled strength making them the go-to choice for heavy-duty applications. But a new contender has emerged, challenging the status quo and promising a revolution in rope technology. Synthetic ropes, crafted from advanced materials like polyethylene and Dyneema, are rapidly gaining ground, offering a range of advantages that make them a formidable alternative to their steel counterparts.

At first glance, synthetic ropes may seem like an unlikely challenger, but their lightweight nature, superior flexibility, and enhanced safety features have turned heads across industries. From rugged construction sites to the serene waters of recreational boating, synthetic ropes are proving their mettle, delivering unparalleled performance and reliability in a wide variety of applications. So, whether you're winching, recovering a vehicle, or embarking on an outdoor adventure, the choice between steel cable rope and synthetic rope could be the decisive factor in your success.

In this comprehensive guide, we'll delve deep into the world of ropes, exploring the key differences between steel cable and synthetic options, their respective advantages and disadvantages, and the diverse industries and markets where each shines. Get ready to discover the game-changing potential of synthetic ropes, and uncover why they are quickly becoming the preferred choice for those seeking a perfect blend of strength, safety, and versatility.

Understanding the Differences Between Cable Steel and Synthetic Rope

When it comes to choosing the right rope for your needs, understanding the differences between cable steel and synthetic rope is crucial. Whether you're winching, recovering a vehicle, or engaging in various outdoor activities, selecting the appropriate rope can make all the difference in terms of safety, performance, and longevity.

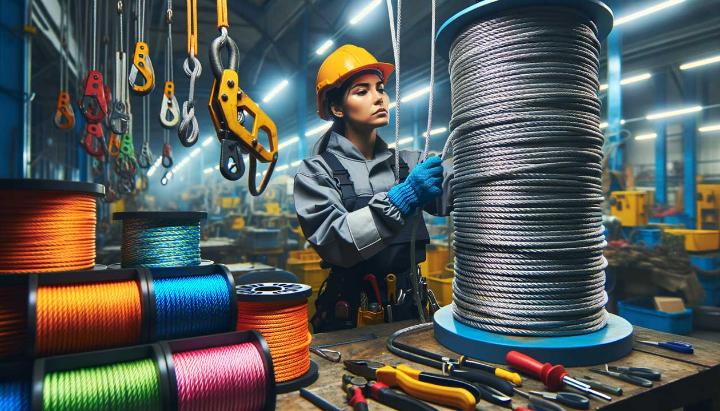

What is Cable Steel Rope?

Cable steel rope, often referred to as wire rope, is a strong and durable rope constructed by braiding or twisting numerous strands of steel wires. Its robust construction provides exceptional strength and resistance to abrasion, making it a popular choice for heavy-duty applications such as winching, rigging, and industrial use.

What is Synthetic Rope?

Synthetic rope, on the other hand, is made from man-made materials like polyester, nylon, or polypropylene. These ropes are lightweight, flexible, and often resistant to certain chemicals or environments. They are commonly used for outdoor activities like camping, yachting, and off-road adventures, as well as in various industrial and marine applications.

Pros and Cons of Cable Steel Rope

- High breaking strength and abrasion resistance, making cable steel rope an excellent choice for heavy-duty tasks and rugged environments.

- Exceptional durability, ensuring a long lifespan even under challenging conditions.

- Potential for kinking, which can compromise the rope's integrity and create potential safety hazards.

- Significant weight, which can make handling and transportation more challenging.

- Potential energy storage, meaning that if the rope fails, it can recoil with tremendous force, posing a safety risk.

Pros and Cons of Synthetic Rope

- Lightweight and easy to handle, making synthetic rope a preferred choice for outdoor enthusiasts and recreational activities.

- Superior flexibility and reduced risk of kinking, ensuring smoother operation and increased safety.

- Lower recoil risk and reduced weight, enhancing safety and ease of use.

- Improved resistance to corrosion and certain chemicals, extending the rope's lifespan in various environments.

- Lower abrasion resistance compared to steel cable, requiring more care and maintenance to prevent premature wear.

- Susceptibility to UV damage or chemical degradation, which can compromise the rope's strength and integrity over time.

- Potential for stretching or fraying, especially under heavy loads or prolonged use.

When deciding between cable steel and synthetic rope, it's essential to carefully evaluate your specific needs, the intended application, and the potential risks involved. Consider factors such as strength requirements, weight limitations, environmental conditions, and safety concerns to make an informed choice that maximizes performance and ensures a safe and successful operation.

Advantages of Synthetic Rope Over Steel Cable

In today's ever-evolving world, synthetic ropes have emerged as a game-changer, offering unparalleled advantages over traditional steel cables. As industries and outdoor enthusiasts seek innovative solutions, the demand for synthetic ropes continues to soar. This section delves into the key advantages that make synthetic ropes a superior choice, highlighting their lightweight yet high-strength properties and enhanced safety features.

Lightweight and High Strength

One of the most compelling advantages of synthetic ropes is their lightweight nature. Crafted from advanced materials like polyethylene or the renowned Dyneema – the world's strongest man-made fiber – these ropes pack an incredible punch in terms of strength while remaining incredibly lightweight. Imagine a rope that outperforms steel cables of the same diameter in terms of breaking strength, yet feels like a feather in your hands.

This unbeatable strength-to-weight ratio not only makes synthetic ropes easier to handle, transport, and maneuver but also ensures durability and longevity. Whether you're tackling heavy-duty jobs or embarking on outdoor adventures, the high breaking strength and resistance to wear and tear ensure that your synthetic rope will be a reliable companion for years to come.

Safety and Ease of Use

Safety should always be a top priority, and synthetic ropes excel in this regard. Unlike steel cables, which can store tremendous potential energy when under load, synthetic ropes are designed to minimize recoil risk. In the unlikely event of a rope failure, the low potential energy stored means a significantly reduced risk of injury or damage.

But the safety advantages don't stop there. Synthetic ropes are less likely to form burrs or kinks, further reducing the risk of injury or equipment damage. Their flexibility and ease of handling make them incredibly user-friendly, allowing you to work with confidence and precision.

Have you ever experienced the frustration of a rope stretching excessively or losing its shape under load? With synthetic ropes, you can bid farewell to such concerns. Thanks to their low elongation factor, these ropes maintain their form and performance consistency, ensuring reliable and predictable behavior no matter the application.

And let's not forget about the abrasion resistance that synthetic ropes offer. Whether you're navigating harsh environments or dealing with rugged terrain, these ropes are up for the challenge, providing exceptional durability and longevity even in the face of wear and tear.

As you can see, synthetic ropes offer a remarkable combination of strength, safety, and ease of use, making them an ideal choice for a wide range of applications. So, why settle for less when you can embrace the future of rope technology and experience the unparalleled advantages that synthetic ropes have to offer?

Diverse Applications and Markets of Synthetic Rope

The versatility of synthetic ropes has opened doors to a multitude of applications across various industries and markets. From the rugged environments of construction sites to the serene waters of recreational boating, these innovative ropes have carved a niche for themselves, offering unparalleled performance and reliability.

Industrial and Construction Applications

Synthetic ropes have become an indispensable tool in the industrial and construction sectors, where strength, durability, and lightweight handling are paramount. High-Modulus Polyethylene (HMPE) ropes, such as those made from Dyneema, are highly sought after for their exceptional tensile strength and resistance to abrasion and chemicals.

These ropes excel in applications like heavy machinery rigging, crane operations, and overhead lifting, where their lightweight nature and high strength-to-weight ratio provide a distinct advantage over traditional steel cables. Additionally, synthetic ropes are less susceptible to corrosion, making them suitable for harsh environments and prolonged outdoor use.

Marine and Fishing Applications

The marine industry has wholeheartedly embraced synthetic ropes for their exceptional performance in aquatic environments. Nylon and polyester ropes are particularly popular for their resistance to moisture, UV radiation, and chemical degradation, ensuring longevity even in the harshest maritime conditions.

Commercial fishing operations rely heavily on synthetic ropes for activities like trawling, longline fishing, and anchoring. Their low stretch and high strength make them ideal for withstanding the immense forces exerted by ocean currents and the weight of heavy loads.

Recreational boating and yachting enthusiasts also appreciate the benefits of synthetic ropes. Their user-friendly nature, coupled with resistance to kinking and ease of handling, make them a preferred choice for dock lines, halyards, and other applications where safety and convenience are paramount.

Outdoor, Sports, and Recreational Applications

Beyond their industrial and marine applications, synthetic ropes have also gained immense popularity in the outdoor, sports, and recreational sectors. Rock climbers, for instance, rely on the low stretch and abrasion resistance of synthetic ropes to ensure a secure and reliable ascent.

Adventure sports enthusiasts, such as those engaged in canyoning, caving, or zip-lining, benefit from the lightweight and easy-to-maneuver nature of synthetic ropes, enabling them to navigate challenging terrains with confidence.

In the world of arboriculture and tree work, synthetic ropes have become an essential tool. Their high strength and low weight make them ideal for rigging and lowering operations, ensuring the safety of both workers and the surrounding environment.

As you can see, the versatility of synthetic ropes has opened up a world of possibilities across diverse industries and markets. With their unique combination of strength, durability, and specialized properties, these innovative ropes continue to revolutionize the way we approach challenging tasks, pushing the boundaries of what's possible and setting new standards for performance and safety.

Unleashing the Power of Customized Synthetic Ropes

In the ever-evolving world of ropes, one trend has emerged as a true game-changer: customized synthetic ropes. As industries and outdoor enthusiasts seek tailored solutions to meet their unique needs, the ability to customize synthetic ropes has become a highly sought-after advantage. Discover the versatility of synthetic jute rope and jute cord, to see an example of innovative customization options.

From construction sites to marine environments, and from adventure sports to tree care, customized synthetic ropes are revolutionizing the way we approach challenging tasks. Imagine being able to design a rope that perfectly aligns with your specific requirements, whether it's a particular strength rating, stretch factor, or even a branded color scheme. The possibilities are truly endless.

Customization Options for Synthetic Ropes

The beauty of synthetic ropes lies in their ability to be tailored to meet your exact specifications. From the rope's core composition to its outer sheath, a world of customization options awaits:

- Colors and Patterns: Whether you need high-visibility ropes for safety or branded colors to represent your company, synthetic ropes can be customized to meet your visual requirements.

- Diameters and Lengths: Depending on the application and load requirements, you can choose the perfect diameter and length for your synthetic rope, ensuring optimal performance and efficiency.

- Material Composition: Different synthetic materials, such as nylon, polyester, or high-performance fibers like Dyneema, can be combined to create a rope with the desired strength, stretch, and abrasion resistance. Discover the advantages of synthetic winch rope for off-road use for an in-depth look into material composition benefits.

- End Fittings and Terminations: From splices to thimbles, synthetic ropes can be customized with various end fittings and terminations to seamlessly integrate with your equipment and ensure secure connections.

The possibilities are truly endless, and the ability to customize your synthetic rope opens up a world of opportunities to enhance safety, improve efficiency, and tailor the rope's performance to your specific needs.

Versatility of Synthetic Ropes Across Industries

One of the key advantages of synthetic ropes is their versatility, which has led to their widespread adoption across a diverse range of industries. From the rugged demands of construction sites to the serene waters of recreational boating, synthetic ropes have proven their worth time and time again.

- Marine and Fishing: The resistance of synthetic ropes to saltwater, UV radiation, and chemical degradation makes them an ideal choice for marine applications. From securing docks to anchoring vessels and trawling lines, these ropes are a trusted companion on the open seas.

- Construction and Rigging: The high strength-to-weight ratio and durability of synthetic ropes make them a popular choice for heavy machinery rigging, crane operations, and overhead lifting in construction sites. Their lightweight nature and resistance to abrasion ensure efficient and safe operations.

- Outdoor Recreation and Adventure Sports: Rock climbers, cavers, and adventure enthusiasts rely on the low stretch and abrasion resistance of synthetic ropes to navigate challenging terrains with confidence. The ropes' lightweight and easy-to-handle nature make them a perfect companion for outdoor adventures. Discover the versatility of 1.5 polypropylene rope for outdoor adventures.

- Tree Care and Arboriculture: In the world of tree care, synthetic ropes have become an essential tool for rigging and lowering operations. Their high strength and low weight ensure the safety of both workers and the surrounding environment, making them invaluable in this industry.

As you can see, the versatility of synthetic ropes, combined with the ability to customize them to meet specific needs, has opened up a world of possibilities across a wide range of industries and applications. Whether you're tackling heavy-duty tasks or embarking on outdoor adventures, customized synthetic ropes offer a tailored solution that ensures optimal performance, safety, and reliability.

Choose the Best Rope for Your Needs: Steel Cable Rope vs Synthetic Rope

When deciding between steel cable rope and synthetic rope, the choice hinges on understanding their unique advantages. A cable steel (or 1 steel cable) is strong, durable, and resistant to abrasion, ideal for heavy-duty applications but poses safety risks like kinking and recoil. In contrast, synthetic rope is lightweight, flexible, and safer with minimal recoil risk, making it favoured for its ease of handling and broad industry applications from marine to adventure sports. Given these benefits, synthetic rope is increasingly seen as a superior alternative. Fill in the form above to learn more about finding the perfect rope solution for your needs.