Polyester line shows about 5 % elongation at break, retains ≥ 90 % tensile strength after 500 h UV exposure, and reaches up to 50,000 lb on a 2″ double‑braid.

Read in 2 min – What you’ll gain

- ✓ Cut stretch in half vs nylon – ≈ 5 % vs ≈ 10 % elongation.

- ✓ Retain ≥ 90 % tensile strength after 500 hours of UV testing (ASTM G154).

- ✓ Strength scales with diameter and braid; confirm with a size–strength chart.

- ✓ Custom OEM/ODM options (colour, branding, core) with bulk pricing as low as $0.04 / ft, depending on specification.

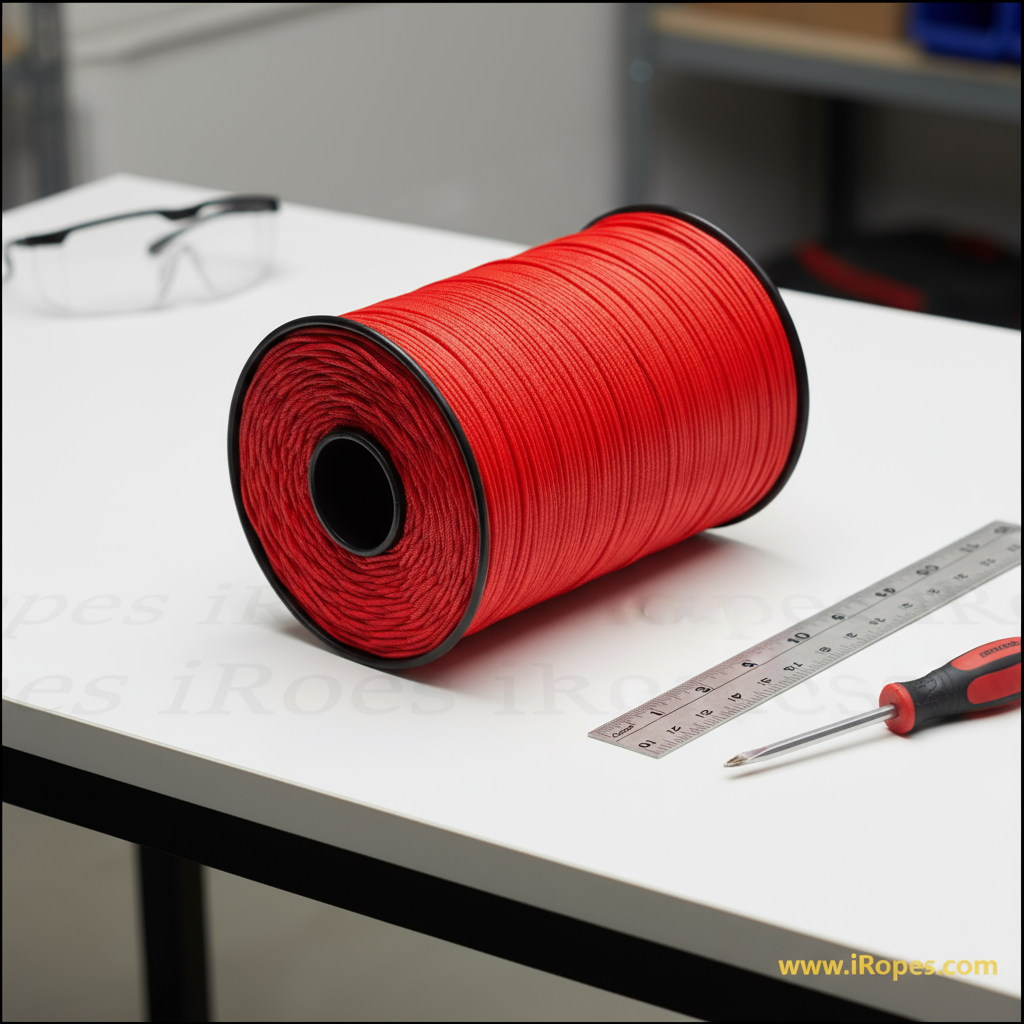

You’ve probably heard that any synthetic rope will stretch like a rubber band, yet polyester line defies that idea—its elongation sits at about 5 % at break, keeping knots tight and loads steady. This isn’t a marketing claim; ASTM‑referenced testing shows ≥ 90 % strength retention after 500 hours of UV exposure. In the sections that follow, we’ll outline key numbers, braid options, and how iRopes can tailor a low‑stretch solution for your toughest projects.

Definition and Core Characteristics of polyester line

Polyester line is a synthetic rope made from polyethylene terephthalate (PET) fibres. It combines high tensile strength, low stretch, and strong resistance to UV, abrasion, and moisture, which makes it a reliable choice for demanding outdoor and industrial tasks across many applications.

- Low stretch – elongates roughly 5 % at break, preserving line length.

- UV resistance – retains strength after prolonged sun exposure.

- Abrasion resistance – endures harsh surfaces without rapid wear.

Manufacturers often label the same material as Terylene, Trevira, or Dacron, so you may encounter any of these names when sourcing the rope.

The rope can be built with PET fibres into solid braid or double‑braid constructions, providing options for strength, handling, and flexibility to suit different load requirements.

“Polyester’s low‑stretch characteristic combined with its UV stability makes it the go‑to rope for any project that demands dimensional consistency under the sun,” notes Dr L. Chen, rope engineer.

Mechanical Performance and Diameter‑Strength Matrix

Now that you know what polyester line is, let’s look at how it behaves under real‑world loads. Its low stretch helps keep tension steady, and strength generally increases with diameter—an advantage that makes sizing decisions more straightforward when you consult manufacturer specifications.

When you pull on polyester line, it elongates roughly 5 % at break—about half the stretch you’d expect from nylon. That modest give translates into tighter knots, precise sail‑trim, and steadier tension when rigging a tree‑work system.

Performance Highlights

Key numbers that matter on the job

Stretch

≈ 5 % elongation at break, offering tighter control than nylon’s ≈ 10 %.

Strength Range

From 100 lb on a 1/8″ solid braid up to 50 000 lb on a 2″ double‑braid.

Load‑to‑Diameter Matrix

Breaking strength rises with diameter and varies by construction—verify with supplier charts for your exact specification.

Environmental Resistance

Durability when the elements bite

UV Stability

Retains ≥ 90 % strength after 500 h of ASTM G154 UV exposure.

Abrasion Index

Scores 7+ on ASTM D 3884, resisting harsh surfaces on docks and construction sites.

Water Absorption

Less than 0.1 % uptake, keeping performance steady in wet conditions.

While exact values depend on construction, larger diameters deliver higher breaking loads. For example, a 1/4″ solid braid is about 1 200 lb, and a 1″ double‑braid is about 6 000 lb—enough for many marine and industrial rigging tasks.

All performance figures reference ASTM standards: stretch (ASTM D 2256), UV (ASTM G154), and abrasion (ASTM D 3884). Verify that suppliers cite these tests for reliable quality.

When you compare polyester line to nylon, the advantages become clear: lower stretch, superior UV protection, and virtually no water absorption. Consequently, the rope stays true longer, especially under high‑sunlight conditions like boat decks or arid construction sites.

Armed with the diameter‑strength guidance, you can match the rope size to the expected load and confirm environmental ratings for your project’s conditions. Next, we’ll explore braid constructions and show which configuration shines in each application.

Construction Types, Braid Options, and Application Areas

Now that you understand how breaking strength relates to size, it’s time to look at the rope’s architecture. The way polyester fibres are formed determines how the line handles and which jobs it excels at.

Polyester line can be built in several ways:

- Solid braid – a single‑layer weave that’s straightforward to splice and works well for moderate loads.

- Double braid – a core covered by an outer sheath, delivering higher tensile capacity and extra abrasion protection.

- Diamond braid – interlaced strands form a rhombus pattern, offering flexibility without sacrificing strength.

- Twisted rope – strands are laid in a spiral (not braided), giving a softer hand that’s useful for general utility.

- Poly‑outer/PP‑core combos – a polyester exterior paired with a polypropylene core, balancing low weight and robust load‑bearing.

These constructions map directly onto the industries that rely on polyester line. Marine crews typically favour double‑braids for halyards and dock lines, with solid braid for onboard utility. Arborists value predictable, low‑stretch handling from double or diamond braids when rigging trees. In fishing, a poly‑outer/PP‑core combo offers reduced weight and buoyancy, while the polyester sheath shields the line from UV. Landscaping and general industrial work often favour solid braid for ease of handling and cost‑effectiveness.

Solid Braid

Single‑layer construction, easy to handle, ideal for general‑purpose loads up to medium strength.

Double Braid

Two‑layer core‑cover design, higher load capacity and better abrasion resistance for heavy‑duty work.

Marine

Mooring lines, halyards and dock ties that demand UV stability and low stretch on boat decks.

Arborist

Rigging for tree climbing and canopy work where precise tension and durability are critical.

When you wonder “Is polyester fishing line better than nylon?”, the answer hinges on stretch and water absorption. Polyester’s roughly 5 % elongation and near‑zero water uptake give a firmer feel and consistent performance, while nylon’s higher stretch can feel softer but reduces precision.

Choosing the right diameter and braid follows a simple decision tree. Start with the maximum load you anticipate, match it to a braid that meets or exceeds that load, then choose a safety factor suitable for your industry (many general‑purpose jobs use ≈ 5 × the working load).

- Identify the maximum load you expect.

- Select a braid that matches that load – solid for light, double for heavy, diamond for flexible.

- Choose a diameter that provides a suitable safety factor (often 5 × the working load).

Armed with this framework, you can move confidently toward the buying guide, where iRopes’ OEM/ODM options let you customise colour, branding, and core material to suit the exact scenario you’ve mapped out.

Buying Guide, Customization, and Frequently Asked Questions

Now that you’ve matched braid and diameter to your load, turn that plan into a purchase that fits your budget and branding. Below are practical items to review before you click “add to cart”.

Buying considerations

- Size selector – choose the diameter that meets or exceeds the required breaking load, then confirm the safety factor you need.

- Price per foot – bulk rolls (500 ft + ) often drop to under $0.05 / ft; specialty colours may carry a modest premium.

- Packaging options – spools, bulk bags, or customer‑branded/non‑branded cartons; ask for colour‑coded labels if you manage several projects.

- Bulk discounts – multiple pallets typically unlock tiered discounts; iRopes ships palletised orders worldwide.

When you need a rope that carries your brand or a unique colour palette, iRopes’ OEM/ODM service can turn those ideas into a finished product. The team will work with you on:

Custom OEM/ODM

Select colours and patterns, specify accessories (loops, thimbles, terminations), and choose the core type (all‑polyester or PP‑core combo). iRopes provides ISO 9001‑backed quality assurance, dedicated IP protection, customer‑branded or non‑branded packaging, and direct pallet shipping to your warehouse worldwide.

Frequently asked questions

What is a polyester line? It is a synthetic rope made from PET fibres, sold under names such as Dacron, Terylene or Trevira. It’s valued for low stretch, UV stability, and durability in harsh conditions.

Does polyester line stretch? Yes—about 5 % elongation at break, roughly half nylon. It also stretches far less than polypropylene, which can reach ≈ 30 %.

Is polyester fishing line better than nylon? It depends on your goal. Polyester offers lower stretch and better UV performance, so it feels crisper under load; nylon’s higher stretch can provide shock absorption.

How do I choose the right diameter for my project? Start with the maximum load, pick a braid that meets it, then apply an appropriate safety factor. For help, speak with iRopes specialists for a tailored recommendation.

Where can I buy polyester line near me? Large hardware chains stock standard sizes, while marine and arborist suppliers carry higher‑strength options. For customised wholesale orders, iRopes ships pallets globally.

Get a personalised rope recommendation

This article outlined the key characteristics of polyester line – its low ≈ 5 % stretch, excellent UV and abrasion resistance, minimal water absorption, and how diameter and construction influence predictable breaking loads. It also compared braid constructions and highlighted iRopes’ OEM/ODM options for colour, branding and core selection.

Ready to apply these insights to your specific project? Our specialists can help you choose the ideal polyester line, size and custom features to meet your load and environmental requirements. Simply fill out the form above and we’ll provide a personalised solution.

For any further questions or a detailed quote, complete the inquiry form above and our team will get back to you promptly.