⚠️ Even "best" marine ropes can fail due to mismatches—not just quality—losing up to 50% strength from UV exposure in a single year. Discover how to choose unbreakable options with 30% better shock absorption, tailored for critical tasks like docking or anchoring.

In 8 minutes, master marine rope selection to prevent failures and boost safety →

- ✓ Pinpoint degradation causes like abrasion, cutting equipment damage risks by 70% through proper material matches.

- ✓ Compare Nylon's 30% stretch versus Polyester's superior UV resistance, gaining skills to select the ideal rope for your vessel's unique loads.

- ✓ Follow application guides for docking or mooring, solving common mismatches that lead to 20% strength loss in wet conditions.

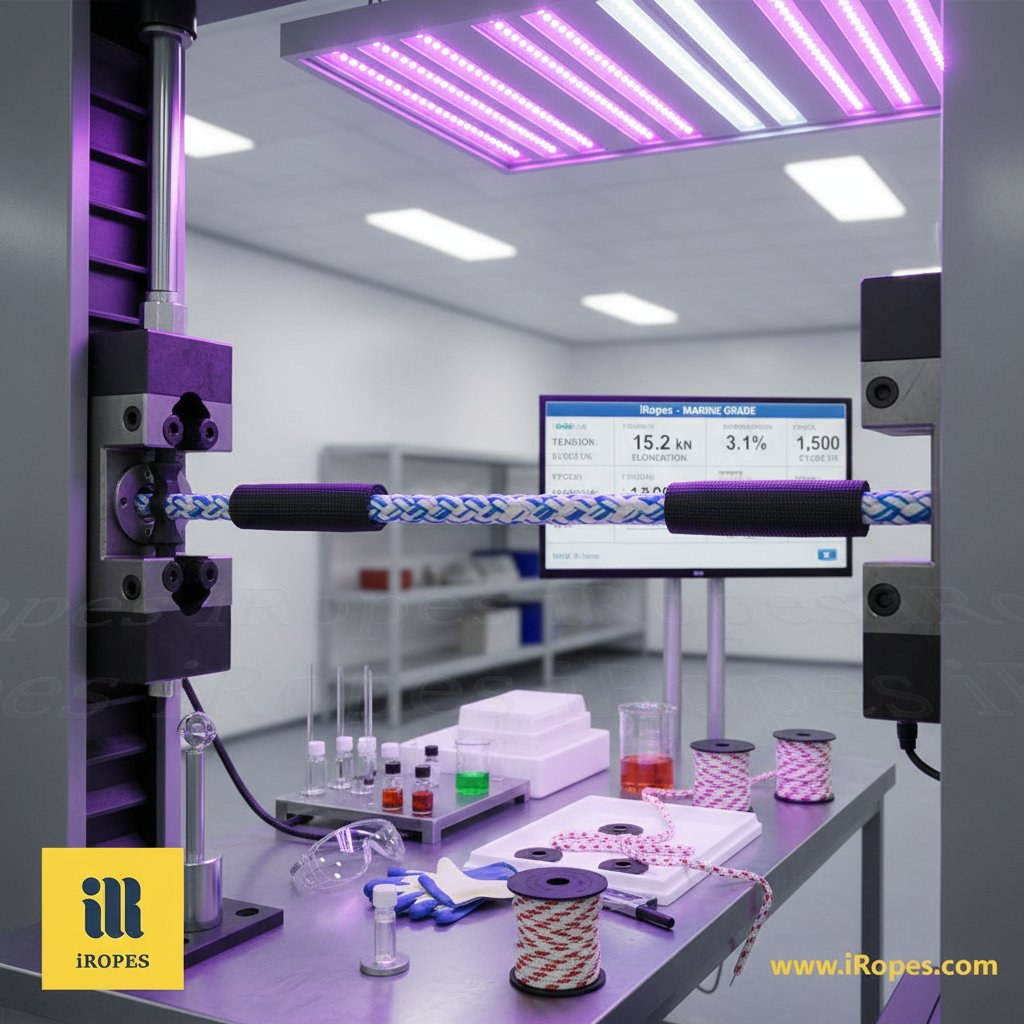

- ✓ Access iRopes' custom ISO-certified solutions, ensuring 15x stronger Dyneema options with efficient global delivery for long-term value.

You trust the "best" marine rope to hold firm, yet waves crash and lines snap—why? Because overlooked factors like water absorption can weaken them by up to 20%, turning safety nets into hazards mid-voyage. What if one counter-intuitive switch in material and construction could make your setup unbreakable, significantly slashing replacement costs and risks? Dive in to uncover the exact criteria that transform vulnerabilities into vessel confidence, providing genuine value and peace of mind.

Why the Best Marine Rope Fails: Common Reasons and Lessons

Imagine you're out on the water, the sun beating down, and suddenly your docking line snaps under the strain of a sudden wave. That heart-stopping moment isn't just bad luck; it's often a sign that even the so-called best marine rope has its limits when pushed incorrectly. I've seen it happen during weekend boating trips, transforming a relaxing outing into a frantic scramble to avoid damage. The truth is, ropes praised as top performers can fail spectacularly if we overlook the basics. Let's break down why this occurs and what we can learn to keep things secure.

One major culprit is material degradation, which can creep up faster than you might think in the salty, sun-soaked marine environment. Prolonged UV exposure from sunlight breaks down the fibres over time, making the rope brittle and prone to snapping. This can reduce a rope's strength by up to 50% in a single year if left unprotected. Water absorption also plays a sneaky role; some materials soak it up, losing up to 20% of their strength when wet, turning a seemingly reliable line into a liability during storms. Then there's abrasion, that constant rubbing against docks, rocks, or even the boat itself, wearing away the outer layers until the core is exposed and vulnerable. Think of it like sandpaper on your favourite jeans; without protection, it all frays eventually.

Another significant issue is selecting the wrong rope for the job, which is far more common than you'd expect. For instance, choosing a low-stretch option like polyester for docking—where you genuinely need that give to absorb kinetic shocks from boat movement—can easily lead to overload and breakage. It's akin to using a stiff spring in a bumpy ride; it holds steady at first but shatters under excessive pressure. Have you ever wondered why your lines feel too rigid during rough ties, causing abrupt jerks? That's the mismatch in action, transforming an otherwise solid choice into a potential safety hazard.

And let's not forget maintenance—or the glaring lack thereof—which seals the fate for many ropes prematurely. Skipping regular inspections for chafe, those insidious cuts from friction, allows small issues to balloon into full-blown failures. What about improper storage? Coiling a wet rope tightly or leaving it exposed to direct sunlight invites kinking, weakening the structure from the inside out. I once had to untangle a deplorable mess from a friend's locker after an unused season, only to find the rope was half as strong as new—a hard lesson learned.

So, what is the best type of rope for marine use? There's truly no one-size-fits-all answer; it critically hinges on your specific setup and application. Nylon excels for its stretch in anchoring, while polyester demonstrates superior resistance against UV rays when used in rigging. Failures often stem from mismatched types—for instance, choosing polypropylene's buoyant lightness for heavy mooring lines overlooks its rapid UV breakdown and lower inherent strength. Getting the fit right is paramount to safety and longevity, positioning you miles ahead in preventing unexpected breakdowns.

Understanding these critical pitfalls clearly demonstrates that smart choices begin with selecting the right materials, precisely engineered to *thrive* in the relentless and demanding marine environment.

- UV Exposure: Sunlight actively degrades fibres, potentially reducing strength by up to 50% over a year if left unprotected.

- Water Absorption: Certain rope materials swell and significantly weaken when saturated, which is particularly critical during prolonged wet conditions.

- Abrasion: Friction from various surfaces erodes the rope's outer sheath, exposing and damaging the crucial inner core over time.

The Best Rope for Marine Use: Essential Materials and Their Strengths

Building on those critical failure points we've identified, let's now dive deep into the specific materials that genuinely make or break a rope's reliability at sea. Choosing the right one ultimately means matching material properties *perfectly* to your operational needs, whether it's handling sudden jerks from unforgiving waves or standing up to constant sun and corrosive salt spray. I've spent enough time on boats to know that the wrong pick can transform a smooth voyage into a logistical nightmare, so getting this selection right is crucial. What works best? It depends entirely on your specific application, but we'll walk through the key options step-by-step to clarify all considerations.

Nylon stands out for its impressive elasticity, capable of stretching up to 30% under load to effectively absorb powerful shocks from wind or tides. That inherent 'give' is an absolute lifesaver for anchoring and mooring, tasks where lines consistently face erratic and sudden pulls—picture it like a strong rubber band easing the jolt instead of snapping abruptly. It's also remarkably strong and offers good abrasion resistance, making it a reliable go-to for vital dock lines. However, here's the catch: when wet, nylon can temporarily lose some strength, and prolonged UV exposure will degrade it over months. For those dynamic, shock-absorbing jobs, though, it's genuinely hard to beat.

Polyester offers a distinctly different performance profile, featuring far less stretch—typically around 10-15%—which keeps things exceptionally precise for running rigging like halyards and sheets. It truly shines in UV resistance, holding its vibrant colour and structural integrity even after multiple seasons under intense sun. Moreover, it shrugs off abrasion far better than most alternatives. Think of it as the steady, dependable workhorse for sails and control lines, where any unwanted stretch leading to slack could compromise performance. On the downside, that inherent low flexibility means it transmits more direct force through the boat, rendering it less suitable for high-impact mooring situations requiring significant shock absorption.

Polypropylene maintains a lightweight and straightforward functionality, effortlessly floating on water thanks to its uniquely low density. This makes it perfect for tow lines or rescue gear, where anything dropped overboard simply must not sink—useful for pulling a skier or retrieving a stray fender. It's often more economical and quick-drying, but its inherently lower strength and rapid UV breakdown make it largely unsuitable for heavy loads; expect it to significantly weaken after a single year in direct sunlight. This material is best reserved for casual, low-stakes tasks where strength is not a primary concern.

For truly extreme demands, Dyneema—manufactured from ultra-high-molecular-weight polyethylene (UHMWPE)—delivers an unmatched strength-to-weight ratio, boasting capabilities up to 15 times stronger than steel on a per-pound basis. It exhibits minimal stretch, making it ideal for high-load applications like lifelines or winch lines, and resists abrasion like an absolute champion. The primary trade-off? It typically carries a higher price tag and can be tricky to splice without specialised tools. So, when considering if nylon or polyester rope is better for general marine use, remember this differentiation: Nylon excels for shock-heavy jobs due to its inherent stretch, while polyester leads in long-term durability for steady tasks where minimal give is required. It's always about balancing dynamic absorption abilities against unwavering longevity, depending on whether waves or wind pose your biggest challenge.

These materials form the fundamental backbone of performance, yet their true power is unleashed only when thoughtfully paired with the correct construction methods tailored for each specific task at hand. This strategic pairing is where true value and reliability are created.

Stretch-Focused

Shock Absorbers

Nylon

High elasticity for anchoring; absorbs waves but can be UV-sensitive when wet.

Polypropylene

Floats for rescues; lightweight yet weakens under prolonged UV exposure.

Best For

Dynamic loads like mooring, where inherent give prevents sudden breaks.

Durability-Focused

Steady Performers

Polyester

Low stretch for rigging; offers top UV and abrasion resistance.

Dyneema

Ultra-strong for high loads; minimal stretch, though at a premium cost.

Best For

Precision tasks like halyards that demand consistent reliability over time.

Marine Rope Guide: Matching Constructions and Applications to Prevent Failures

Now that we've thoroughly covered the core materials and their individual strengths, the next crucial layer is understanding how those fibres get meticulously woven—or twisted, in some cases—to create marine ropes that genuinely hold up in real-world scenarios. Rope construction isn't just about aesthetics; it's the fundamental factor that dictates how a rope handles twists, constant pulls, and continuous use without giving way. I've personally tinkered with various types during my own outings, and matching the specific build to your exact operational needs has saved me from more than a few logistical headaches. Let's explore the primary constructions and how they effectively pair with specific applications to completely dodge those common pitfalls we discussed earlier.

Let's start with three-strand twisted ropes, a classic choice that's as straightforward as its name suggests: three bundles of fibres meticulously twisted around each other in a helical pattern. This time-tested design offers robust durability and makes splicing—a technique where you intricately weave the ends together for an incredibly strong and seamless connection—remarkably straightforward, even for beginners. It possesses inherent shock absorption capabilities because the twist provides some 'give' under load, which is precisely why it's perfect for both anchor and mooring lines. Picture securing your boat in genuinely choppy waters; that natural flex effectively cushions against sudden surges without kinking up excessively.

Moving to double braid, this construction represents a significant step up in sophistication: an outer braided sheath expertly covers an inner braided core, collectively creating a smooth, round profile that is both flexible and incredibly strong. It demonstrates superior resistance to kinking compared to twisted styles, gliding effortlessly through blocks and winches, which is an absolute game-changer for halyards—the lines that raise your sails—and sheets that precisely control them. On a yacht, where handling efficiency matters as much as outright strength, this sophisticated construction keeps operations smooth and significantly reduces wear from repeated adjustments. I distinctly remember swapping to double braid on a friend's rigging; the dramatic difference in smoothness during a windy tack was undeniable. For more on mastering double braid yacht rope splice secrets, explore advanced techniques that elevate performance.

Then there's single braid, which ingeniously omits the core for a simpler, fully braided tube that boasts exceptional lightness and superior flexibility. This makes it ideal for dynamic control lines in racing sails or even specific spearfishing setups where rapid, tangle-free deployment is absolutely critical. While it's not designed for the heaviest loads, its ease of handling truly shines in dynamic, low-weight applications. Have you ever struggled with bulky, cumbersome lines during an intense race? This specific style effectively cuts down that frustration, offering a smoother, more responsive experience.

Putting it all together, the real magic happens when you meticulously match construction to the exact task. For docking a boat, confidently choose

These precise pairings transform potentially weak links into genuinely reliable assets. However, to achieve truly

Twisted Builds

Durable for anchors; easy splicing and absorbs shocks in rough seas.

Braided Cores

Flexible for rigging; resists kinks efficiently in high-movement yacht tasks.

Docking

Nylon double braid for superior bump absorption and easy cleat handling.

Anchoring

Nylon three-strand with chain for optimal scope and unwavering stability.

Choosing Unbreakable Marine Ropes: Quality Indicators, Criteria, and iRopes Solutions

Those smart pairings of construction and application we just explored provide a solid groundwork, but what truly separates genuinely

At the very heart of any truly reliable line are its intrinsic performance characteristics, starting unequivocally with tensile strength—the maximum specific load a rope can effectively bear before breaking. This is often rated in thousands of pounds for marine grades. Always look for options where the working load limit, typically about one-fifth of that breaking point for optimal safety, perfectly matches your vessel's unique needs; for a 30-foot vessel, that might practically translate to at least 5,000 pounds for critical docking lines. Elongation, or precisely how much the rope stretches under pressure, directly correlates to its shock-absorbing capability—high values, such as 20-30% for nylon, critically help absorb sudden jerks from waves, thereby actively preventing abrupt snaps. Energy absorption goes hand in hand with elongation, measuring exactly how well the rope dissipates force from impacts; think of it as a built-in, dynamic buffer that transforms potential disasters into manageable tugs. Without these characteristics perfectly balanced, even the most robust build can fail precisely when it counts most. For deeper insights into understanding marine rope specifications and uses, review detailed guides on performance metrics.

Durability extends these considerations further, actively guarding against the environment's relentless toll. UV resistance is a paramount criterion, with premium ropes engineered to retain up to 80% of their strength even after a full year in direct sunlight, unlike cheaper alternatives that crumble much sooner. Abrasion protection necessitates robust outer layers or the strategic use of chafe gear—simple tubular sleeves that wrap vulnerable spots, significantly extending a rope's lifespan by shielding it against sharp dock edges or rough hawse pipes. Chemical resistance also holds significant importance, especially in areas frequently exposed to fuels, oils, or harsh cleaners; modern synthetics excel here, holding up reliably without degrading or rotting, unlike older natural fibres. Have you ever noticed how salt spray seems to accelerate wear? These critical factors collectively ensure ropes remain functional and reliable through countless seasons of vigorous marine exposure.

What about overall value? This extends far beyond just the initial upfront cost—longevity means significantly fewer replacements, potentially saving commercial fleet operators thousands of dollars over several years. Always seek out ISO 9001-certified manufacturers, as this certification guarantees consistent, premium quality resulting from precise manufacturing processes and rigorous quality assurance. Customisation significantly amplifies this value: you can precisely tweak diameters from perhaps 1/2 inch up to 2 inches for a perfect load-bearing fit, incorporate high-visibility colours for enhanced safety, or include essential accessories like thimbles—which are metal inserts that flawlessly prevent crushing at eye splices. What is marine rope primarily made of? Today, it's typically crafted from advanced synthetics like nylon and polyester, prized for their truly premium durability and performance in constantly wet, corrosive, and salty marine environments, vastly outperforming natural alternatives that degrade rapidly. To learn more about the benefits of 12-strand nylon and braided rope options, check out specialized applications for marine settings.

For a comprehensive buying guide, especially if you're sourcing wholesale, commence by meticulously assessing all your specific applications—calculate precise loads, then expertly match appropriate materials and constructions. Partner with specialised providers like iRopes for comprehensive OEM and ODM setups, where you can precisely dictate specifications for custom-branded lines. iRopes proficiently handles everything from intricate design tweaks to robust intellectual property (IP) protection, diligently safeguarding your innovations. Opt for efficient direct pallet shipping to streamline logistics and minimise hassles, with production and delivery timelines as impressively tight as four weeks for global destinations. This highly streamlined path consistently delivers cost-effective, custom-tailored, and genuinely unbreakable ropes that significantly boost overall operational efficiency.

- Assess Needs: Meticulously list all operational loads and environmental conditions to precisely guide material selections.

- Specify Custom: Precisely choose diameters, crucial colours, and essential add-ons through bespoke OEM/ODM services.

- Verify Quality: Always confirm ISO certification and meticulously review all test data to ensure peak performance.

- Secure Delivery: Conveniently arrange efficient global shipping with robust IP safeguards for complete peace of mind.

Prioritising these crucial elements not only effectively averts unexpected breakdowns but also significantly streamlines marine operations, ensuring lasting success and reliability.

Armed with comprehensive insights into why even the best marine rope can tragically fail—from insidious UV degradation and material mismatches to neglected maintenance—you are now thoroughly equipped to make genuinely smarter, safer choices for all your boating adventures. This detailed marine rope guide precisely highlights how selecting the best rope for marine use, such as high-stretch nylon for dynamic anchoring or durable polyester for unwavering rigging, strategically paired with optimal constructions like double braid for secure docking, consistently ensures truly unbreakable performance. Always prioritise critical factors like tensile strength, superior UV resistance, and bespoke custom features from ISO-certified manufacturers like iRopes to perfectly match your specific applications, ultimately delivering exceptional long-term value and paramount safety on the water.

Whether you're meticulously outfitting a single yacht or managing a large wholesale fleet, applying these stringent criteria transforms potential pitfalls into confidently reliable assets, effectively saving both precious time and unnecessary hassle in even the harshest marine conditions.

Need Tailored Advice for Your Marine Rope Needs?

If you're ready to thoroughly explore custom solutions or have specific questions about sourcing genuinely unbreakable ropes for your exact setup, the inquiry form above connects you directly with expert iRopes specialists for personalised guidance and unparalleled support.