Polypropylene rope floats, delivering alongside its buoyancy an impressive 26,800 lb breaking strength in a 1.5‑inch line—gaining you exceptional load capacity without sacrificing the advantages of floatation 🎯.

Quick Wins – 2 min read

- ✓ Floats on water, eliminating lost lines and speeding up inspections.

- ✓ Up to 30 % lower cost per foot versus nylon, while often matching strength.

- ✓ Custom colours, lengths & terminations that align with your branding or safety codes.

- ✓ ISO‑9001 certified quality, guaranteeing consistent performance across global shipments.

Most engineers assume the toughest line must be a heavy, sinking nylon. However, iRopes' 1.5‑inch polypropylene rope disproves this traditional assumption, offering an outstanding 26,800 lb breaking strength while remaining buoyant. This unique combination of buoyancy and power allows for swift wear detection, reduced downtime, and effective budget management. Discover how the efficiency of a floating rope can revolutionise your marine, industrial, or decorative projects without compromising on performance.

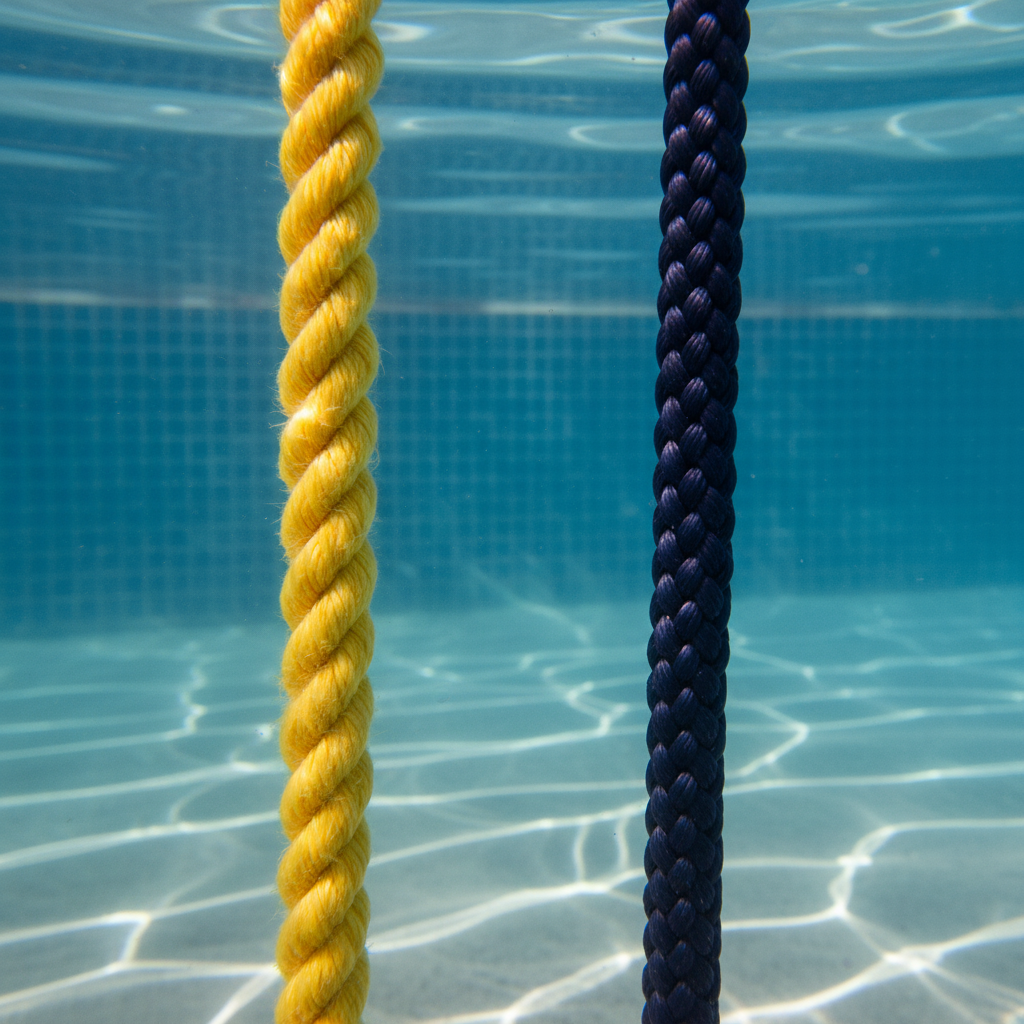

polypropylene rope float

When your project demands a rope that remains on the surface rather than sinking, polypropylene is the ideal material. iRopes, a leading manufacturer of various rope products, produces this lightweight fibre in bulk, ensuring consistent, reliable performance for all water-based applications.

Polypropylene’s chemical composition gives it a density of approximately 0.90 g/cm³, which is significantly lighter than water’s 1.00 g/cm³. This lower density means the rope naturally rises and maintains buoyancy. This isn’t due to trapped air; it's an inherent physical property that allows the rope to float even when fully saturated.

Will polypropylene rope float? Absolutely. Its low density ensures it stays on top of water, unlike materials such as nylon or polyester, which typically sink.

- Marine mooring – The rope remains visible on decks and docks, greatly simplifying line handling and retrieval.

- Pool safety lines – Floating markers alert swimmers and prevent entanglement beneath the water's surface.

- Rescue floatlines – A buoyant lead line enables rescuers to deploy and retrieve equipment efficiently without it sinking.

“Choosing a rope that floats significantly reduces hazards for boaters and pool owners alike – it’s a crucial safety feature that should not be overlooked.” – Marine safety consultant.

Because the rope stays visible on the water's surface, you can inspect it quickly and replace it proactively before any wear becomes a critical issue. If your new project requires buoyancy alongside impressive strength, the next section will compare polypropylene with nylon, helping you select the material that perfectly matches your exact requirements.

polypropylene nylon rope

Having explored the floating characteristic of polypropylene, a direct comparison with nylon is essential. This will help you determine which material best suits the specific demands of your project.

- Buoyancy – Polypropylene remains afloat, which enhances line visibility. Nylon, conversely, tends to sink.

- Elasticity – Nylon stretches significantly under load, offering effective shock absorption. Polypropylene, by contrast, has very limited stretch.

- Durability – Polypropylene notably resists rot, mildew, and many chemicals. Nylon, however, excels in resisting abrasion and high temperatures.

- UV resistance – Nylon generally performs better under prolonged sunlight exposure. Without adequate protection, polypropylene can degrade more quickly.

So, which is better, polypropylene or nylon rope? The optimal choice genuinely depends on your specific priorities. Choose polypropylene when you need a rope that is highly visible on water, tolerant of chemicals, and offers cost‑effective strength. Opt for nylon if properties like stretch, superior abrasion resistance, and robust performance under long‑term UV exposure are more critical for your application.

Selecting the right rope

Begin your selection by considering the operational environment. Water‑based applications typically favour polypropylene, whereas tasks involving high stress or extensive sun exposure benefit more from nylon. Next, evaluate the importance of stretch: a forgiving nylon line is ideal for tasks requiring shock absorption, while a low‑stretch polypropylene line excels in secure tie‑down scenarios. Finally, weigh your budget constraints; polypropylene often provides comparable strength at a lower price point.

With a clear understanding of the trade‑offs between these materials, the next logical step is to examine a specific size that many wholesale buyers frequently request: the 1.5‑inch polypropylene rope.

1.5 inch polypropylene rope

After exploring the differences between rope materials, you’ll discover that the 1.5‑inch diameter is a workhorse, frequently requested by wholesale buyers. This substantial diameter translates into a remarkable breaking strength of approximately 26,800 lbs, providing a massive safety margin for even the most demanding tasks.

Because this rope can handle such significant loads while remaining lightweight, it is highly valued across several heavy‑duty environments. Below is a concise visual guide to its most common applications and the various ways iRopes can precisely tailor this product to your exact specifications.

Heavy‑Duty Uses

Where strength meets reliability

Mooring

Secure dock lines that remain visible and resist rot in harsh marine environments.

Restraints

Industrial tie‑downs capable of handling substantial loads without unwanted stretching.

Stanchions

Robust decorative posts for events or landscaping that require high load capacity and aesthetic appeal.

Custom Options

Tailor‑made to fit your project

Lengths

Order standard spools from 100 ft to 2,000 ft or request precise custom cuts to size.

Colors

Choose high‑visibility yellows, essential safety reds, or specific brand‑aligned hues.

Construction

Select from 3‑strand, hollow braid, or double‑braid designs for specific splicing requirements or enhanced durability.

Whether you require a rope capable of mooring a large vessel or a resilient line for an industrial safety barrier, the 1.5‑inch polypropylene option offers the ideal combination of strength and flexibility. iRopes’ comprehensive OEM/ODM capabilities allow you to specify the exact length, colour, and braid type, ensuring the rope arrives perfectly suited for its intended application. Next, we will detail how iRopes guarantees exceptional quality and safeguards your intellectual property throughout the entire manufacturing process.

Custom Solutions and Quality Assurance

iRopes operates a state‑of‑the‑art manufacturing facility, proudly holding ISO 9001 certification. This means that every coil—whether it’s a buoyant polypropylene rope float or a heavy‑duty 1.5 inch polypropylene rope—undergoes rigorous inspections before leaving the factory. This certification system also meticulously safeguards the intellectual property of every custom design, ensuring your brand‑specific patterns and specifications remain confidential from raw material sourcing to the final packaging. Our portfolio also includes high‑tensile nylon ropes, detailed in our Super Strong Rope guide.

Material

Choose from pure polypropylene, specialised nylon blends, or innovative polypropylene‑nylon hybrids to perfectly meet your buoyancy, stretch, or chemical‑resistance requirements. For high‑visibility needs, consider our yellow polypropylene rope.

Size & Colour

Specify any diameter—from ¼‑inch up to 1.5 inch—and select from high‑visibility yellows, essential safety reds, or your precise corporate palette.

Accessories

Add essential accessories like thimbles, eye‑splices, loops, or custom‑printed tags. Packaging options include individual bags, branded colour boxes, or durable cartons tailored to your needs.

IP Protection

Every custom specification is comprehensively covered by robust non‑disclosure agreements and secure data handling procedures throughout the entire production cycle.

ISO 9001

Continuous improvement audits guarantee material consistency, product traceability, and reliable on‑time delivery for all bulk orders.

Global Shipping

Direct pallet dispatch to locations worldwide ensures your customised ropes arrive ready for immediate deployment, streamlining your logistics.

Wholesale partners gain significant advantages from tiered pricing, fast‑track production slots, and dedicated account support for every project.

Whether you're ordering a standard reel of floating rope for marine safety or a bespoke 1.5‑inch polypropylene rope for a specialised industrial rig, iRopes integrates certification, intellectual property security, and worldwide logistics into a single, highly reliable supply chain. The final section of this guide will summarise the key takeaways and explain how you can initiate a custom‑order conversation today.

Ready for a customised rope solution?

Need more tailored advice? Complete the enquiry form above, and we’ll help you choose the ideal rope for your specific application.

iRopes, a leading specialist in nylon woven rope manufacturing, also supplies high‑performance polypropylene solutions. You now understand that a polypropylene rope float will remain on the water’s surface, that a polypropylene nylon rope offers a clear trade‑off between buoyancy and stretch, and that the 1.5‑inch polypropylene rope delivers approximately 26,800 lb breaking strength for vital marine mooring or industrial restraints. You can also explore the detailed polypropylene rope breaking strength tables. Our ISO‑9001 certified OEM/ODM facilities can tailor diameter, colour, construction, and packaging to your precise specifications, ensuring a perfect fit for your needs.